Engineers in the US and Australia have gained a significant amount of funding to further their research into novel aerospace and electronics 3D printing applications.

Over in Australia, Hypersonix Launch Systems has been awarded $2.95 million by the nation’s government to fund the development of a hydrogen-powered UAV, which it’s building using 3D printing ‘where possible.’ In the US, meanwhile, NextFlex has issued $17 million to projects seeking to advance the R&D of flexible electronics, including 3D printed Radio Frequency (RF) and hypersonic flight-related parts.

”This latest round of projects focus broadly on critical FHE manufacturing developments that have been prioritized in the NextFlex FHE Manufacturing Roadmaps,” said Malcolm Thompson, PhD, an Executive Director at NextFlex. “These projects will develop groundbreaking capabilities that will transition to industrial practice and benefit US manufacturing.”

NextFlex in ‘FHE’ development

Founded under a US Air Force Research Laboratory agreement in 2015, NextFlex is an organization that represents electronics firms, academic institutions, nonprofits and government partners, with the shared goal of facilitating the R&D of Flexible Hybrid Electronics (FHEs) with the potential to advance US manufacturing interests.

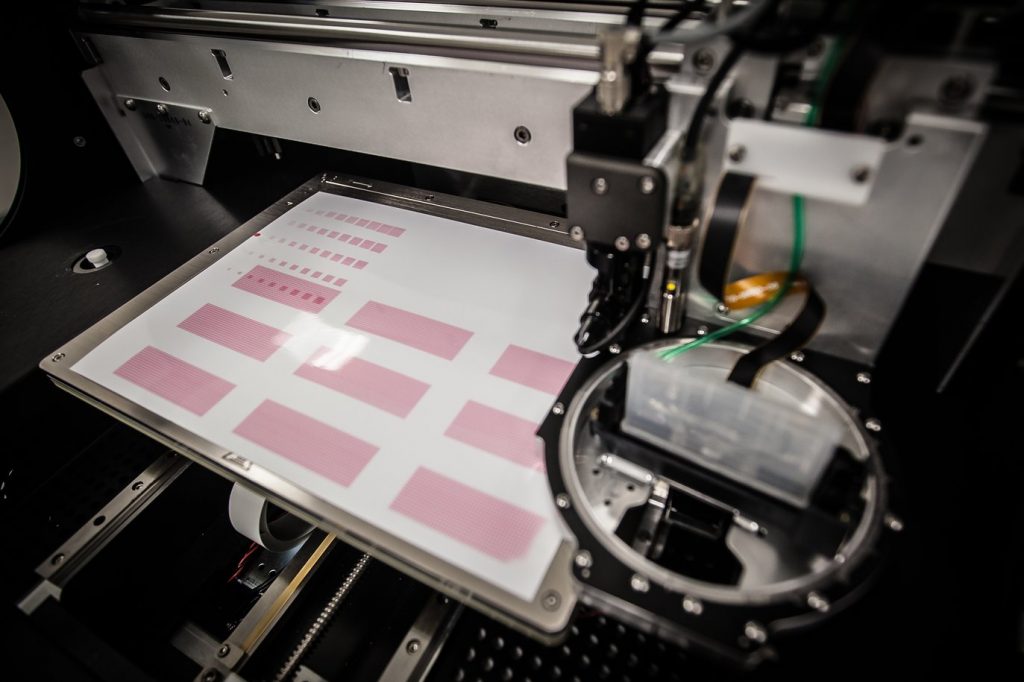

To achieve its goal of fostering FHE adoption, NextFlex continues to build public-private partnerships with those developing approaches that have the potential to drive the technology’s commercialization. In the past, the group has sought to facilitate such advances via its in-house Technology Hub, which is fitted with inkjet, aerosol jet and extrusion 3D printers, as well as production and testing spaces.

The consortium has also gained a huge amount of AFRL funding to pass onto any promising FHE development projects it can find, including an initial $75 million upon its foundation. Since then, the group has gone on to enter into a further cost-sharing agreement that has seen the US DoD commit to providing it with up to $154 million more, lending it the spending power needed to support cutting-edge R&D.

Most recently, in February, NextFlex also launched its seventh Project Call, through which it made another $11.5 million available to those honing novel methods of FHE production, and having concluded its sixth, it has now revealed the winners.

The beneficiaries of Project Call 6.0

As part of its sixth Project Call, NextFlex has awarded $17 million to fund a total of 18 projects working to promote FHE technology R&D, as well as its adoption across the USA’s advanced manufacturing sector. These winning entries are set to focus on developing a wide range of electronics, ranging from those optimized for use in harsh environments to low-cost 5G antennas, but not all relate to 3D printing.

Of the projects fortunate enough to receive backing, it’s been confirmed that four of these are basing their approaches around additive manufacturing. Using some of the funding provided by NextFlex, for instance, a team at GE Research is said to be 3D printing RF parts for hypersonic flight applications, while another is honing Integrated Deposition Solutions (IDS) for additive manufactured circuitry.

Given the sensitive nature of some of the defense research being conducted, only a minute amount of detail has been published about the winning projects. However, from what’s been released, we know that Lockheed Martin is also looking into the reliability of 3D printed RF devices, albeit those created via Direct Ink Writing (DIW), and a team at Auburn University is focusing on closed-loop inkjet control.

As with NextFlex’s other Project Calls, its sixth edition will see participants cover cost share contributions, hence its $17 million funding announcement does include $8.5 million from the winners themselves. That being said, the initiative takes the group’s total funding issued over the $116 million mark, with more set to be awarded in the near future.

Hypersonix’s UAV 3D printing project

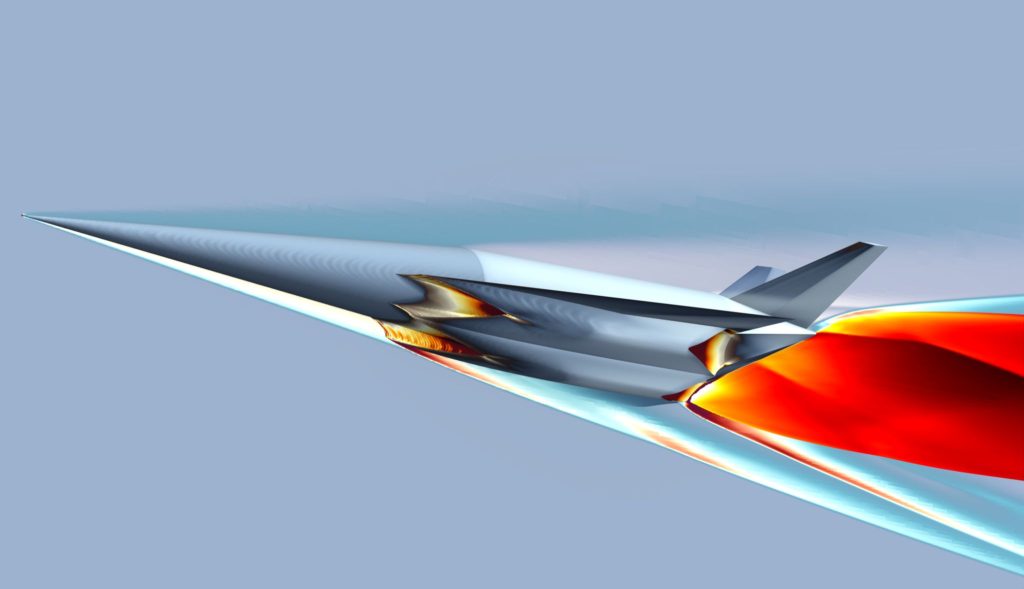

In other hypersonic technology-related news, Hypersonix has gained a $2.95 million grant, along with the University of Southern Queensland, LSM Advanced Composites and Romar Engineering to aid its ambition of building a unique reusable UAV.

Designed to disrupt the global aerospace launch market, the DART CMP is a composite version of the DART AE vehicle, which is set to be powered by the SPARTAN hydrogen-fuelled scramjet engine, enabling it to hit speeds of up to Mach-12. Successfully tested in a shock tunnel last year, the propulsion system is also said to provide a five times higher specific impulse than traditional rocket engines, while weighing around 60% less to boot.

Leveraging the funding received via their Cooperative Research Centres Projects (CRC-P) grant, the program’s engineers aim to develop a process of building the vehicle’s frame from high temperature oxide-oxide ceramic matrix composites (CMCs).

While the exact role 3D printing will play in the build of the UAV remains unclear, it’s understood that the technology will be used to produce its lightweight parts whenever feasible. In fact, a dedicated additive manufacturing team led by ex-SpaceX man Steve Milanoski is already being assembled for the project, providing a strong indication of the extent to which the technology will be utilized.

Having already gained an Accelerating Commercialisation program or ‘ACA’ federal grant, Hypersonix is now seeking to push ahead with the development of its UAV, with the project expected to enter full swing in July 2022, and yield specialized materials for its aeroshell, control surfaces, flight avionics and fuel system by 2025.

“We are very excited to be working with Hypersonix, USQ and LSM on the development of the DART CMP,” concludes Romar Engineering CEO Alan Lipman. “The project represents a significant leap forward in technology for the fast-growing Australian space industry.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a diagram of Hypersonix’s upcoming ‘DART AE’ UAV. Image via the University of Southern Queensland.