Premier manufacturer of industrial and consumer 3D printers Stratasys Ltd. has announced today a partnership with the UK’s brand new robotics facility, the Engineering and Physical Sciences Research Council (EPSRC) National Facility for Innovative Robotic Systems at the University of Leeds. The new center will house, in addition to advanced robotic building equipment, the Objet1000 from Stratasys, the largest multi-material 3D printer in the world, and the Objet500 Connex3, the company’s multi-material, multi-color 3D printer – supplied by Stratasys UK reseller Tri-Tech 3D.

The facility, backed by £4.3 million in funding, will act as a site for researchers and local industry to partner with companies to create cutting edge robotics. Director of the center, Dr Robert Richardson, explained the facility’s mission, “Robotics has been identified by the Government as one of the areas where the UK can develop a technological edge, therefore it’s our vision to build a world-leading centre for robotics and autonomous systems. We looked at the most innovative and exciting robots being developed across the world and asked ourselves what kit we’d need to build something even better. With our 3D printing technology, we’ll be able to make robots that are smaller, more intricate, more flexible and more integrated than ever before. Leeds already has a great track record in robotics for surgical applications, patient rehabilitation, prosthetics, and exploration, but the new facility will revolutionise our ability to turn new concepts into reality.”

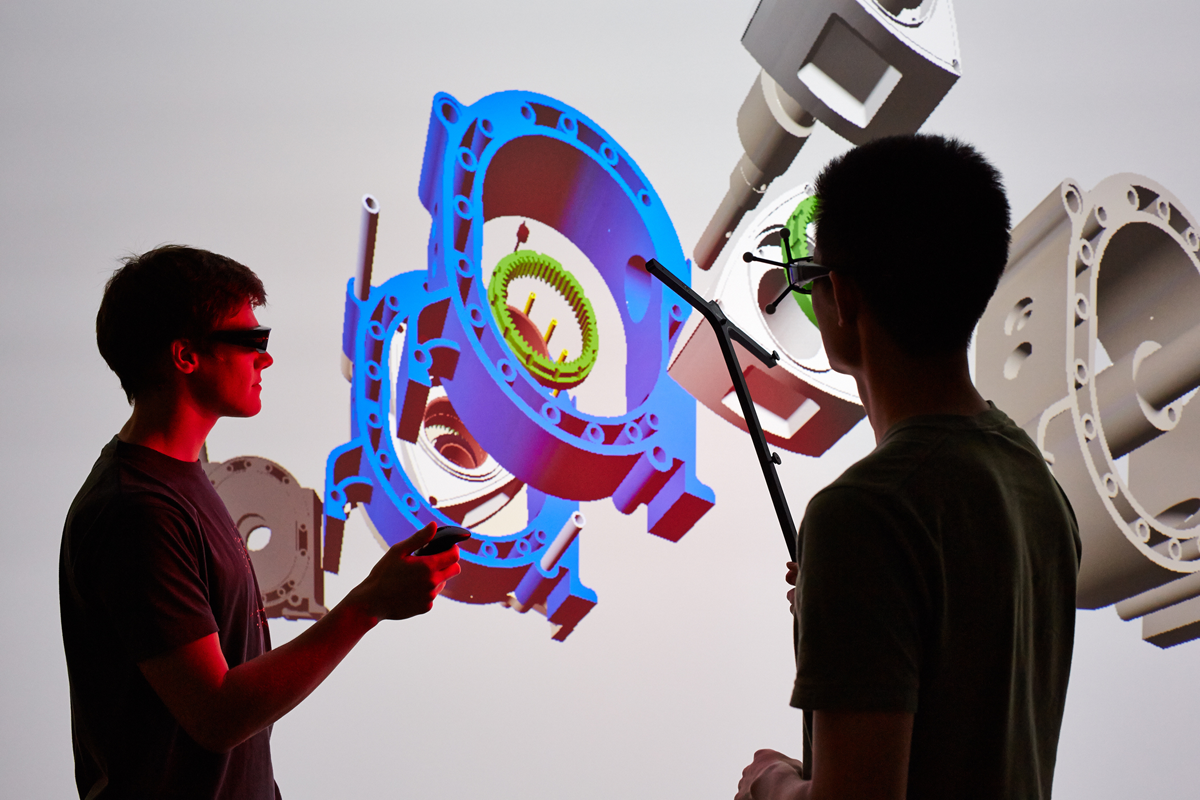

In addition to the Stratasys machines, the National Facility for Innovative Robotics features the Perfactory 3 Mini Multi Lens 3D Printer, a Fusion3D 1100 Laser Structuring System, and a LASER CAB Laser Welding System. Outside of 3D printing, the center has a complete 3D visualization studio for the creation and inspection of 3D models before being 3D printed and a number of subtractive manufacturing tools, such as a CNC mill and laser cutter. If all of that isn’t enough to make you fly to the UK and study robotics, then I don’t know what is!