Polish deep-tech hardware company Sygnis has entered into an agreement with Adam Mickiewicz University, granting it an exclusive license to utilize a new method for modifying filament.

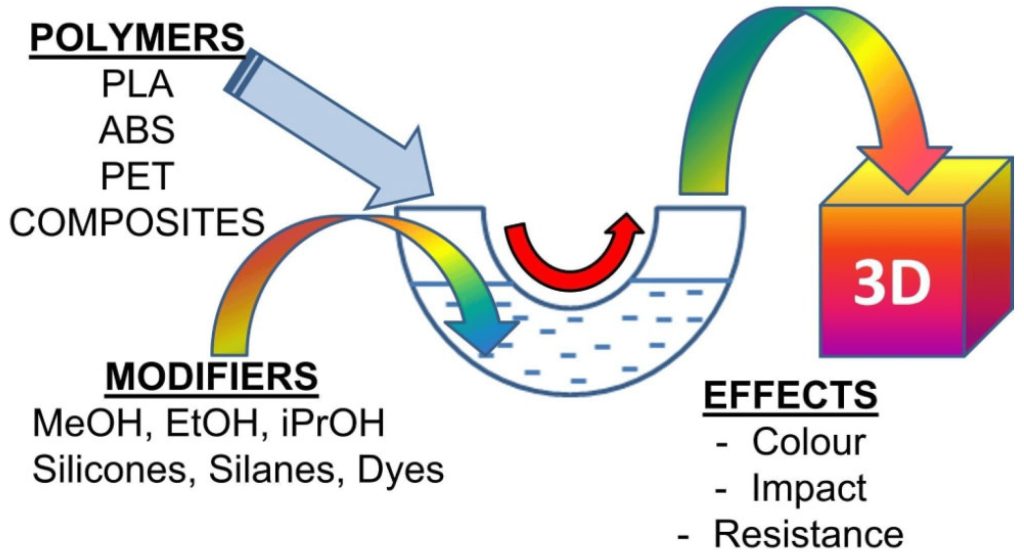

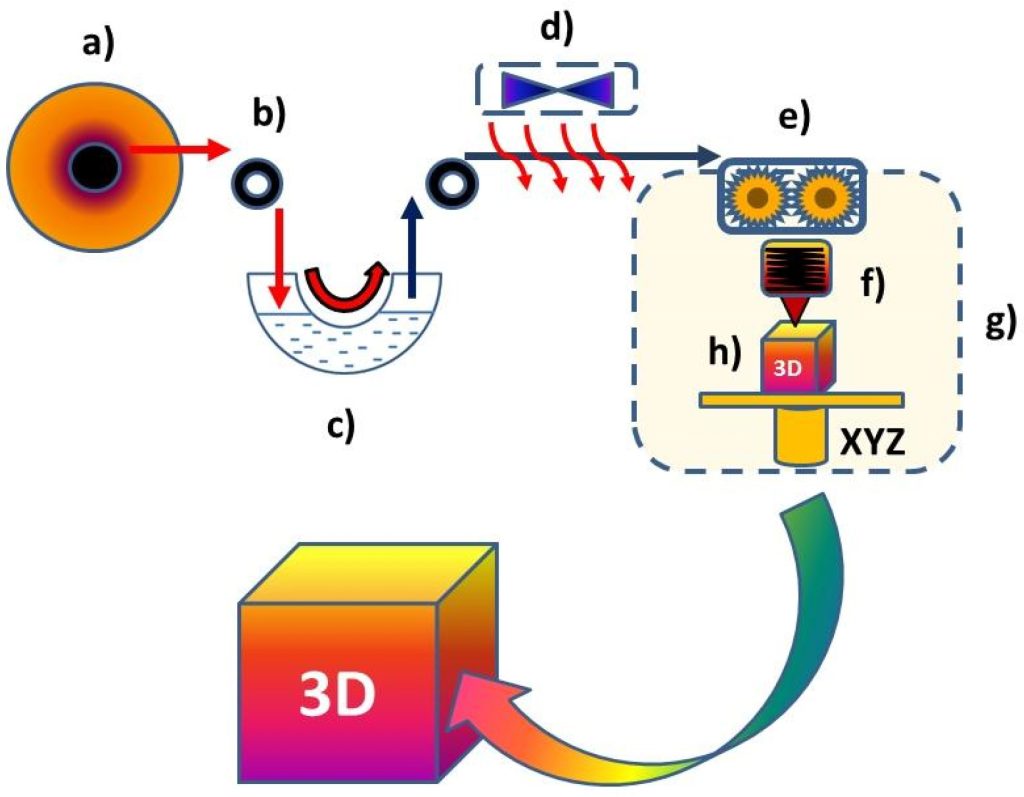

The Liquid for Fused Deposition Modeling Technique (LFDM) allows for the direct incorporation of various chemical substances such as chemicals, antibiotics, dyes, pesticides, trace elements, radioactive materials, nanoparticles, proteins, fertilizers, peptides, phosphors, monomers for polymerization, and active ingredients during the 3D printing process using a standard FDM 3D printer with polymer material. With the introduction of the proposed LFDM technology, it becomes feasible to incorporate chemical substances into polymer filaments that were previously difficult to apply due to undergoing chemical or physical transformations during traditional processing. Additionally, LFDM eradicates the requirement for expensive and energy-intensive processing equipment, making it accessible for use in any laboratory by users without access to specialized devices.

Combining chemistry with 3D printing

The agreement’s license serves as a focal point covering the manufacturing, marketing, sale, and distribution of products resulting from the implementation of the mentioned method. This license has been granted for the territory of Poland until June 27, 2033, in exchange for royalties, which will be determined based on the revenue generated from the sale of products utilizing this method.

Acquiring the license is expected to boost the company’s revenue from 3D printing accessories/peripherals over the 10-year license term, while also expanding its presence in the processing and chemical markets. Successful collaboration with Adam Mickiewicz University in Poznań for the method’s commercialization will further foster the company’s partnerships with scientific institutions.

“It is a unique and simple concept of how to directly combine chemistry with 3D printing. The method was developed in our team 3 years ago. After preparing the patent application, we have published our solution and encourage you to use the LFDM method and its further creative development,” says Prof. Robert E. Przekop from Adam Mickiewicz University in Poznań.

Reflecting on Sygnis’ 3D printing journey

In response to the former Russian military invasion in Poland, 3D printing software developer 3YOURMIND collaborated with Sygnis and start-up backer TeenCrunch to support the ‘Tech Against Tanks’ initiative. The project aimed to facilitate the production and distribution of 3D printed medical, tactical, and protective equipment from various 3D printing hubs and makers located in Poland, Germany, and Ukraine. As part of the initiative, Sygnis provided more than twelve machines and 3D printing materials on-site in Lviv, Ukraine.

Sygnis was successful in recreating two historical artifacts using 3D modeling techniques. The first ideal replicas of the Order of the John III Sobieski and the Order of Immaculate Conception of the Holy Virgin Mary were created after nearly 300 years of absence. Utilizing Digital Light Processing (DLP) technology in 3D printing, Sygnis achieved a high level of precision during the process, with accuracy reaching tens of microns. After being cast in brass and carefully hand-painted, the Orders were transported to the Foundation of the Order of John III Sobieski for safekeeping.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows LFDM technique 1. Image via Sygnis.