In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions across our industry.

Today’s edition features a host of new partnerships from within the industry, new aerospace and army additive applications, reimagined 3D printing facilities, industry partnerships and of course, 3D printed 300 year old Polish artefacts.

Read on for the most recent updates from FIT AG, Fictiv, Rapid Application Group, Elementum 3D, ExOne, DI Labs, Jabil and more.

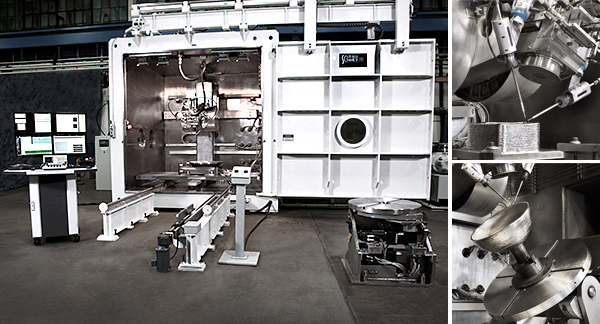

Business: Sciaky’s surge in demand, FIT AG founds subsidiary

Starting with business news, metal 3D printer manufacturer Sciaky Inc has announced that despite the COVID-19 pandemic, it has seen a surge in demand for its Electron Beam Additive Manufacturing (EBAM) and EB welding solutions. Over the past two months, the company has reported a dozen new aerospace projects, ranging from high-level R&D to the manufacturing of prototypes and production parts. While the exact details of the work cannot be revealed as the company signed nondisclosure agreements (NDAs), the projects involved a variety of high-value materials, such as titanium, Inconel, niobium and copper-nickel.

“Sciaky’s EBAM metal 3D printing technology provides the widest availability of cost-saving options for selecting high-value metal materials and producing large-scale parts,” said Scott Phillips, President and CEO of Sciaky, Inc. “Every project is a new opportunity for Sciaky to prove the benefits of EBAM, which proves the industry is actively looking for new solutions to improve upon old processes.”

German 3D printing service bureau FIT AG has founded a Czech subsidiary named FIT Eurazio. The new company has already agreed to cooperate extensively with fellow Czech 3D printing laser technology specialists 4ISP, in order to broaden the FIT Group’s range of products and services. As part of the deal, the FIT Group will integrate the services and products of 4ISP into its portfolio, including the production of prototypes and small series parts made using sheet metal. A production facility will be established in the Czech town of Modletice for this purpose, and in return, FIT Eurazio will market the additive development and manufacturing services of the FIT Group in Central and Eastern Europe.

“4ISP and FIT are both specialists in the use of lasers in the production of metal components, each with their own focus,” said Carl Fruth, CEO of FIT AG. “With this cooperation, we are launching the new Laser Technology division in the FIT Group, in which we will make our specialist know-how available to manufacturing companies of all kinds. This means, we will also be able to offer technical prototypes made of sheet metal to our existing prototyping customers.”

ADM’s 3D printed COVID-19 swabs given approval

Additive manufacturing service provider Precision ADM has announced that their CANSWAB nasopharyngeal swabs are the first Canadian-made COVID-19 testing product to receive Health Canada approval. The 3D printed swab demonstrated the necessary collection capability, and has been clinically tested and proven statistically to be equivalent to a traditional flocked swab. Having received approval, Precision ADM has secured an additional 20,000 square foot facility in order to manufacture and ship hundreds of thousands of CANSWAB nasopharyngeal swabs per week. The company has received multiple orders from Canadian Provincial Governments, and aims to produce two to four million swabs per month, in order to meet the needs of Canadians and other countries.

“We have been manufacturing surgical products such as spine devices and joint replacements for a long time, but during this pandemic, we have taken steps to make sure we are doing all we can to support a secure domestic supply chain for our healthcare system in Canada,” said Precision ADM’s CEO, Martin Petrak. “Adding additional 3D printing capacity to our operations will enable us to produce essential testing equipment in North America and help our communities faster.”

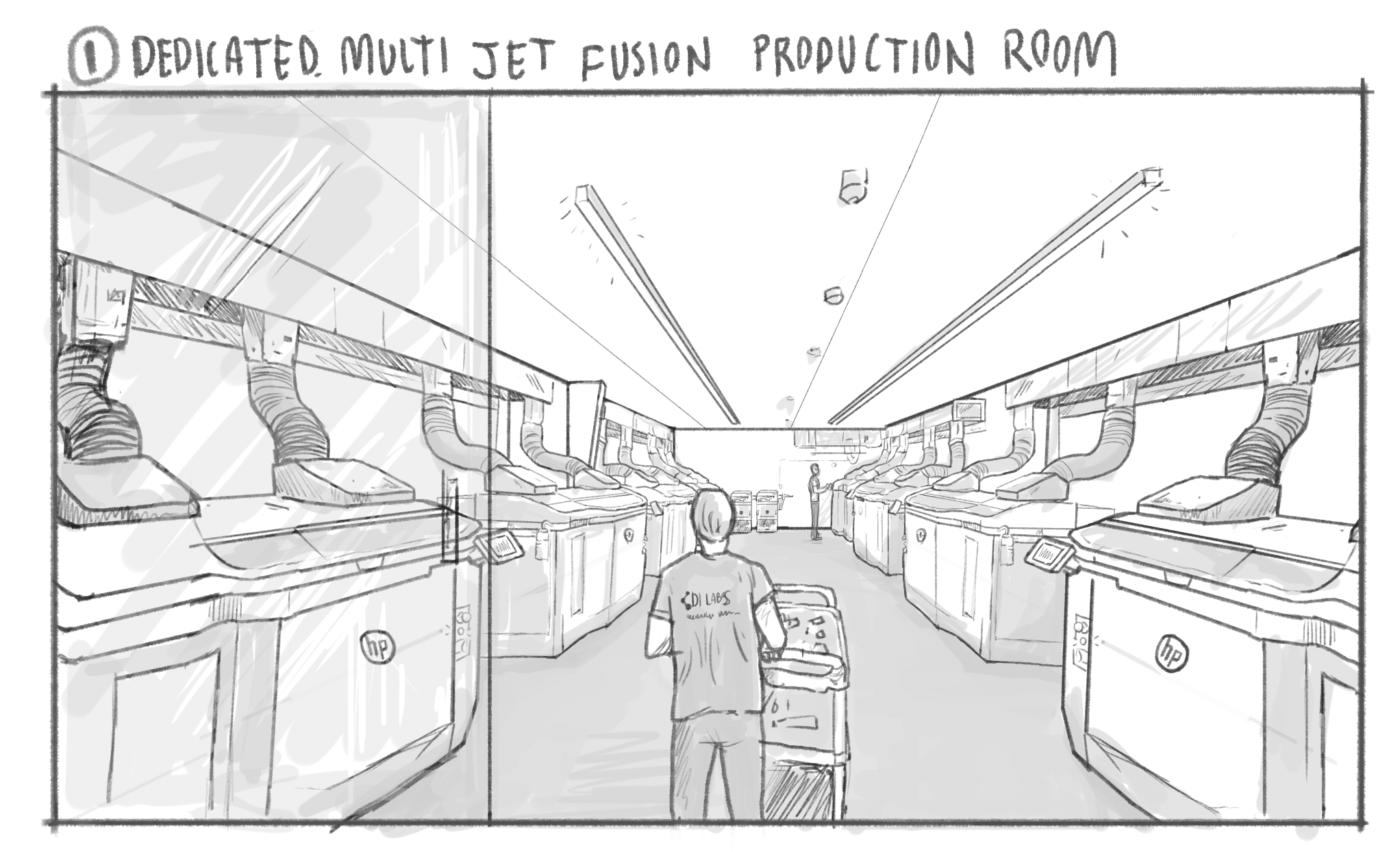

DI Labs to open new 3D printing facility

3D printing services company DI Labs has announced that it will be opening a new “completely reimagined” 20,000 sq/ft innovation lab next month. The lab is being constructed in order to meet market demand, and to tackle industry challenges, including medical equipment shortages caused by COVID-19. In addition, the facility will also act as a testing center for 3D printing technologies and a resource for companies looking to leverage additive manufacturing for competitive advantage. Set to be completed this summer, the company will reveal the inner workings of the lab via an interactive livestream on August 19th, 2020.

“History has shown that success in product development and manufacturing requires extreme flexibility, especially in volatile times like these,” said Carl Douglass, Co-Founder and President of DI Labs. “With our product innovation experience and our unique additive capabilities, we have a significant opportunity to help clients leverage additive technologies to accelerate their innovation process, adapt to market changes, reduce capital expenses and pivot their strategies to meet changing market conditions.”

The latest industry printing partnerships

Oklahoma-based 3D printing service provider Rapid Application Group (RAG), has begun working with neighbouring plastic injection moulding company Gavco Plastics. The deal will amalgamate their services to provide a centralised group, capable of taking parts from prototyping right the way through to mass production. As the businesses are located so closely together, they are now able to seamlessly take parts from prototype and iteration, into Low Rate Initial Production (LRIP) or mass production using injection molding. By combining their services, the companies will enable their customers to eliminate unnecessary costs, by reducing the need for initial tooling and inventory costs.

“This year has shown how fragile supply chains can be and it is time for new innovation in how parts are produced,” said Randall Gavlik, CEO of Gavco Plastics. “This partnership with RAG means we can help customers regain balance in their supply chains while maintaining agility and responsiveness to economic conditions.”

3D printing services company Fictiv meanwhile, has teamed up with global manufacturing services firm Jabil, to create an innovative “digital thread.” The agreement will connect the services of both companies to reduce the risks associated with mass manufacturing, streamline the supply chain and support customers from quote through to completion. Additionally, the deal allows for a seamless handoff from prototype and low-volume production orders with Fictiv, to full-scale mass production with Jabil. This will enable the customers of both companies to take advantage of a quicker, more efficient, and agile process.

“Accuracy, speed and agility are vital to success in volume manufacturing,” said John Dulchinos, VP of Digital Manufacturing for Jabil. “Fictiv’s commitment to data accuracy, combined with Jabil’s investment in lean manufacturing, reduction in business systems and overarching digital infrastructure, enable fast, nimble production ramps.”

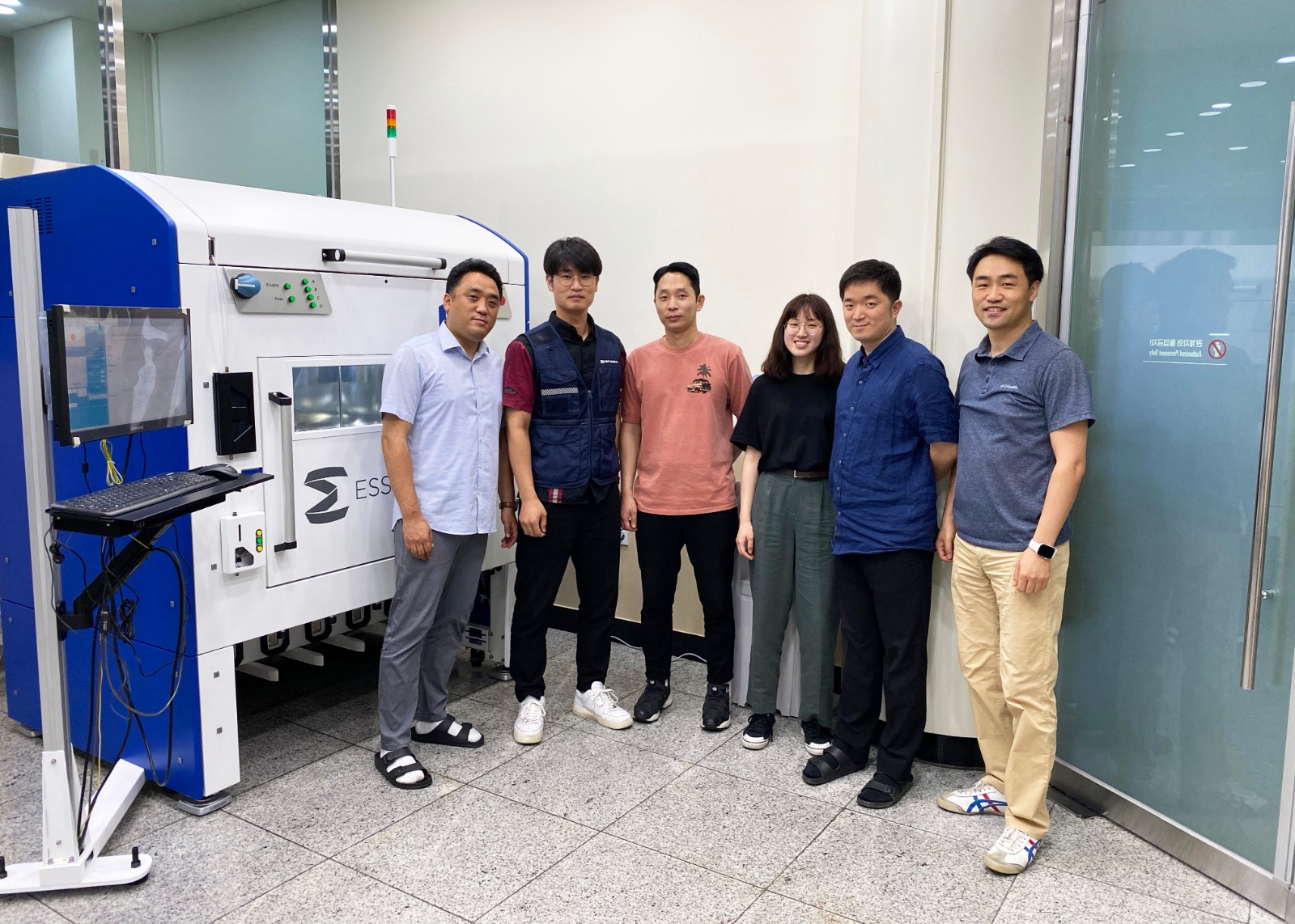

Texas-based 3D printer provider Essentium Inc has announced a distribution deal with South Korean 3D printing specialist Hephzibah. The Korean company will now distribute Essentium’s High Speed Extrusion (HSE) 180-S Series’ low-temperature, standard and high temperature platforms, while offering the complete range of Essentium’s materials portfolio. Hephzibah hopes that combining its customer support expertise with the speed and economic advantages of the Essentium’s 3D Printing platform will lead to the wider adoption of the technology within the South Korean market. Essentium meanwhile, is “hugely excited” about the potential applications of its 3D printing technology on Korean factory floors.

“The speed, scale, and economics of the Essentium HSE 3D Printing Platform present huge efficiencies and improved time-to-market opportunities for our customers,” said Joseph M.G. Lee, President and CEO of Hephzibah. “The fact that Essentium is an open platform means that our customers will benefit from greater innovation agility.”

Printing materials news from VELO3D and ExOne

Californian metal 3D printer provider VELO3D has announced that it has qualified a new 3D printing material for use with its Sapphire 3D systems, expanding on its ability to produce parts for power generation applications. Hastelloy X, a nickel-based alloy designed for use within the laser powder-bed fusion (LPBF) process, features high resistance to cracking and oxidation caused by corrosion. As a result, it’s most often used to manufacture parts for gas turbine engines or combustion-zone components due to its high temperature strength.

Air mobility and power generation company Sierra Turbines, recently partnered with VELO3D to utilize the new Hastelloy material, 3D printing a 20-kilowatt microturbine engine prototype. In future, using VELO3D’s SupportFree process, which reduces the need for support structures when creating parts with complex passageways, Sierra aims to 3D print 95 percent of its engine. For VELO3D, Hastelloy X joins the list of compatible materials with its Sapphire printers alongside Titanium64, INCONEL alloy 718, Aluminum F357, and Hastelloy X.

“Power generation applications such as industrial gas turbines are a key focus for VELO3D so it is important that we qualify the right materials to serve that market,” said Benny Buller, founder and CEO of VELO3D. “We will continue to add more of these types of compatible materials that enable customers to print parts they couldn’t before, yet with even better material properties than those produced by traditional manufacturing.”

Industrial binder jetting specialist ExOne has added two new stainless steels to its updated Quick Ship metal 3D printing service. The platform’s metal production center now offers high-density, precision parts in 316L and 17-4PH materials, which will be used to create 3D printed products on the company’s Innovent+ and X1 25Pro systems. ExOne’s Quick Ship service, allows customers to upload a qualifying digital design file for an instant quote and purchase. The company has also launched a new Quick Ship online dashboard, where customers can instantly get a quote and purchase uploaded designs, as well as create an account to track the project.

“The launch of Quick Ship services for single-alloy metals represents a key step forward in our development of metal binder jetting, and one that signifies our continued confidence in this technology,” said Rick Lucas, ExOne Chief Technology Officer and VP of New Markets. “We also have plans to expand the number of material offerings and size of printable parts in our Quick Ship services by year-end.”

Sygnis 3D printing supports research and recreates artefacts

Polish 3D printing service provider Sygnis New Technologies has successfully recreated two historical artefacts. Using 3D modelling, it was able to create the first ideal replicas of the Order of the John III Sobieski and the Order of Immaculate Conception of the Holy Virgin Mary for nearly 300 years. Moreover, 3D printing using Digital Light Processing (DLP) technology allowed Sygnis to achieve a high level of precision within the process, with accuracy down to a level of tens of microns. After being cast in brass and hand-painted, the Orders were transported to the Foundation of the Order of John III Sobieski for safe keeping.

Sygnis 3D printing technology has also been used to support a team of scientists from the Faculty of Chemistry of the University of Warsaw (UW). Utilizing the company’s rapid prototyping capabilities, the team conducted their research into tracking changes in the distribution of electron density in different molecules. Based at the SOLEIL synchrotron facility near Paris, the test chamber for the team’s experiment was different to that used during initial testing in Warsaw. Sygnis FDM 3D printing technology allowed the team to produce several prototype PLA adapters, in a short-time, enabling them to continue their research, and to take advantage of their three days at the well-equipped experimental facility.

“It was the first such trip of our research group. It was important because it was to check whether the type of experiment we are interested in can be carried out at this particular station,” said Dr Makal, a researcher on the experiment. “It would be convenient for several reasons – the station is located in France, so relatively close, access is easy, you can easily organize and conduct an experiment there in a short time. It was very important to us that our rehearsals could take place.”

Additive applications from SPEE3D, Stratasys, Elementum 3D

Finishing with the latest applications, global energy management firm Schneider Electric has saved more than €20,000 by installing Stratasys FDM 3D printers at its Puente la Reina plant based in Navarra, Spain. As part of a broader ‘Smart Factory’ project, the company is strategically deploying 3D printing, alongside the benefits of the Industrial Internet of Things (IIoT) to drive process optimization. Stratasys F170 3D printers were deployed for a range of tooling applications, including assembly-line tools, jigs, fixtures, robot grippers and other end-of-arm tools – all of which were previously outsourced to third parties. Since integrating Stratasys systems into its workflow, the plant has achieved significant cost-savings in addition to driving overall efficiencies and reducing time-to-market in key areas.

“With this technology we’re able to produce new high-performance production tools in just one day, whereas it would have taken at least one week to outsource the same tools previously,” said Manuel Otamendi, Industrialization and Maintenance Manager of Global Supply Chain at Schneider Electric’s Puente la Reina plant. “This crucially reduces our dependency on suppliers and gives us much more control over tool production, which has increased the overall flexibility of our manufacturing process and accelerated our time-to-market for many products.”

In military applications, Phillips Federal, a division of Phillips Corporation, has begun working with Australian metal 3D printer manufacturer SPEE3D, in order to progress its 3D printing program at its Rock Island Arsenal (RIA) base. Utilizing the company’s LightSPEE3D machines, which are capable of printing aluminum parts in minutes, the US Army is hoping that it will address many of its current readiness challenges in the field. SPEE3D recently conducted successful trials of its WarpSPEE3D systems in collaboration with the Australian Army in the country’s Northern Territories, and the US Army is optimistic about achieving similar successes.

“We are very pleased to join forces with SPEE3D at RIA,” said John Harrison, President of Phillips Federal. “Their unique technology and capabilities will be located at RIA’s Center of Excellence for Advanced Manufacturing in the support of developing future applications for expeditionary forces. SPEE3D adds another terrific dimension to our P3’s growing scope of additive solutions supporting RIA’s manufacturing innovation objectives.”

Finally, California-based aerospace start-up Masten Space Systems has successfully demonstrated an electric fuel pump that was 3D printed by additive manufacturing materials producer Elementum 3D. Manufactured using Elementum’s A6061-RAM2 alloy, the 3D printed e-pump was designed and produced by Masten as part of its mission for the NASA Artemis Program i.e. the project aiming to bring humans back to the moon. Utilizing 3D printing, the device was able to offer cost and weight savings as well as superior performance compared to the turbine-driven pumps typically used for propulsion systems.

“There are a couple of reasons that the A6061-RAM2 is really popular. The first is that there’s name recognition—it is based on one of the most common aluminum alloys used, 6061,” said President of Elementum 3D Dr. Jacob Nuechterlein, speaking 3D Printing Media Network. “There are companies that have 90% to 100% of their parts made from A6061, which I think is part of it as well. In general, the material is highly versatile due to good corrosion characteristics, high ductility, and good weldability.”

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo on part of SPEE3D’s WARPSPEE3D system, which will be used by the US Army to make advances in its 3D printing program. Image via SPEE3D.