Researchers from Princeton University and Georgia Tech have designed an all-new kind of porous structure inspired by nature – and it can be 3D printed.

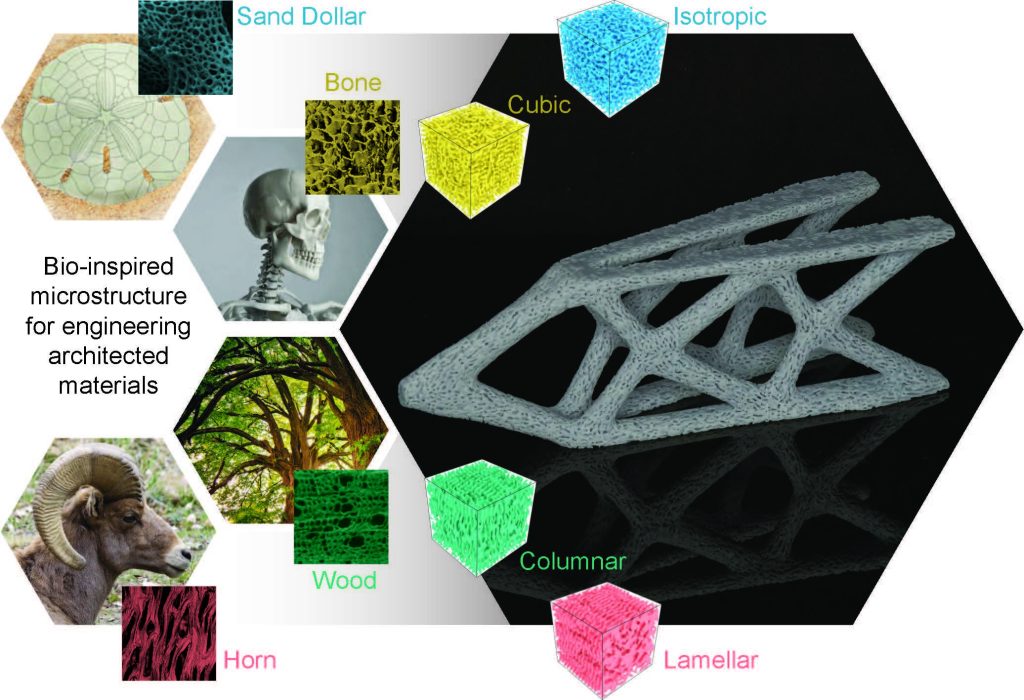

Based on materials such as bone and wood, the novel structure features special pores called spinodal microstructures, which are holes that can be modified and fine-tuned to achieve a variety of part properties and behaviors. Objects containing these spinodal microstructures are typically lighter than a fully-dense counterpart, all while providing customizable stiffness profiles.

The team has already leveraged SLA 3D printing technology to prototype several parts based on spinodal microstructures, including facial implants and lightweight aircraft engine components.

Davide Bigoni, a professor at the University of Trento who was not involved in the research, said, “The authors have found a clever way to allow a continuous transition between zones with different architectures. This is the ultimate concept of biomimicking, as all natural structures form continuous systems. This is a fact known since ancient times—’natura non facit saltus’—nature does not make jumps.”

Nature’s affinity for holes

Many of nature’s structural materials such as bones, horns, and wood are highly porous. As well as making materials light, pores can have specific functions too, such as allowing fluids to pass through. In the case of bones, pores also lend themselves to a remodeling process that can increase or decrease the density of the bones as a response to forces.

As such, the engineering world can greatly benefit from mimicking nature’s porous materials, but developing synthetic counterparts with similar properties has historically been very challenging.

The Princeton team jumped this hurdle with the help of topology optimization technology. The work is based on the basic premise that you can modify a microstructure with holes of different sizes, shapes, and orientations, which ultimately means that performance can be customized.

Specifically, the holes can be shaped like spheres, diamonds, columns, or lentils. By varying the shape and orientation of the holes, the resulting materials can be loaded with different stiffness profiles, while the size of the holes can be varied to control the materials’ densities.

“We have a technique that is quite powerful in the sense that it combines material architectures with optimization at different scales and its integration with additive manufacturing,” said Glaucio Paulino, principal investigator on the project. “It can have a broad range of applications in the sense that it scales, so it can be applied in nano- and microtechnology, as well as at meso- and macroscales.”

Facial implants and aircraft parts

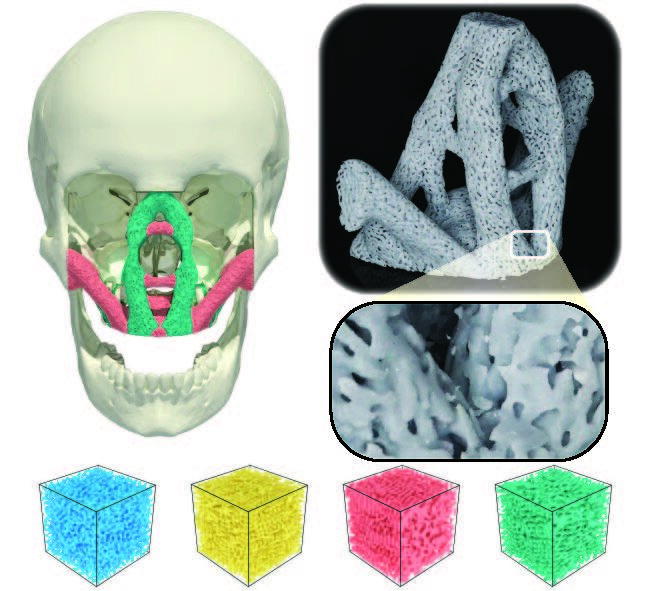

To field-test their newly-designed microstructures, the researchers firstly 3D printed a prototype of a facial bone implant. Bone implants are usually manufactured out of porous titanium to support osseointegration, whereby the bone grows into the holes of the implant. But conventional implants don’t offer the same customizability that spinodal microstructures do.

In this case, the team combined column and lentil-shaped holes, resulting in an implant that was stiff enough to withstand chewing forces and porous enough to encourage bone growth. Although the part was prototyped in resin, it could also be 3D printed in a biocompatible material for an end-use case.

“It’s not the base material that is better. It is the microscale features that are better,” adds Emily Sanders, a co-author of the study. “In theory, we could make the scaffolds out of any material—most appropriate would be to explore biocompatible materials.”

The team also 3D printed a spinodal jet engine bracket: a critical aircraft component that needs to be both strong and light. In this case, the team was able to 3D print smooth transitions from one microstructure to another throughout the part, connecting the pore network without generating weak points in the microstructure. This ultimately resulted in a stronger part design more suitable for the application.

Further details of the study can be found in the paper titled ‘Optimally-Tailored Spinodal Architected Materials for Multiscale Design and Manufacturing’.

As we’ve seen many times before, additive manufacturing can greatly benefit from mimicking structures, natural or otherwise, that already exist. Just this month, a Georgia Tech research project looked at how principles from the art of origami can be used in conjunction with 3D printing to design lightweight and flexible structures capable of changing shape. The work is expected to have applications in everything from 3D printed multifunctional robotics to morphing bridges and collapsible radiofrequency components such as antennae.

Elsewhere, researchers from the University of Freiburg and the University of Stuttgart previously drew inspiration from the propagation mechanism of the air potato plant (Dioscorea bulbifera) to 4D print wearable medical devices that self-adjust to the anatomy of the patient. The printed systems can be pre-programmed to carry out complex movements when exposed to moisture.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the bio-inspired 3D printed facial implant. Image via Princeton University.