The nominations for the 2021 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Welcome to the latest edition of our 3D printing jobs and career moves update for the additive manufacturing sector. If you are looking for a new position in the industry, we keep our 3D Printing job board updated with the latest positions. You can easily apply to any of the posted jobs after creating a free profile.

If you are just about to enter the sector, we offer a guide on how to get a job in the 3D printing industry. The 3D Printing Industry jobs board is also free to use for employers to find 3D printing experts for their businesses.

Read on for an exciting job opportunity at Relativity Space, as well as career updates from Markforged, Tangible Solutions, Azul 3D, Black Buffalo 3D, Additive Industries and more.

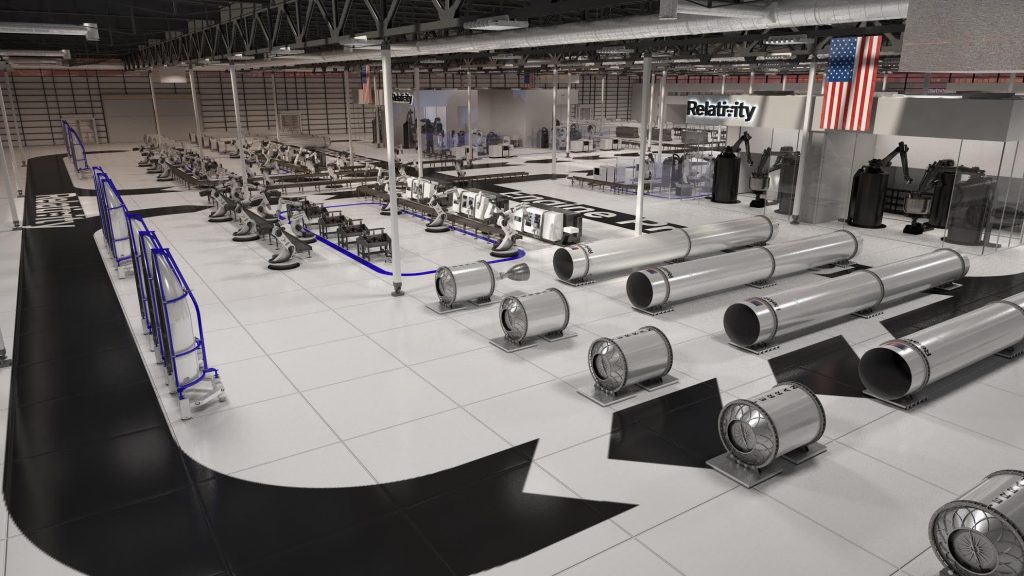

Additive Manufacturing Technician at Relativity Space in California, USA

3D printed rocket manufacturer Relativity Space is seeking an Additive Manufacturing Engineer to work at its autonomous factory in Long Beach, California. As a member of the firm’s small-scale 3D printing group, the successful applicant will be expected to develop processes and procedures that help get the most from its LPBF, SLM, DMLS and DMLM machines, and yield end-use flight-ready parts.

The ideal candidate will have worked with sensitive precision systems before, spending at least three years operating in aerospace or advanced production, while experience with powder machines would also be beneficial. More generally, Relativity Space is looking for an engineer with great communication skills and an intense attention to detail, that’s passionate about human space exploration.

The full job description for the role of Additive Manufacturing Technician at Relativity Space can be found here.

Career moves at Markforged, Azul 3D and more

Starting this week’s appointments with 3D printer manufacturer Markforged, the Massachusetts-based firm has hired John Howard as its new VP of Engineering. In-role, Howard is set to leverage his industry experience of more than 30 years, to lead the company’s hardware engineering team, while reporting to its CEO Shai Terem.

Howard has built a career around developing and launching cutting-edge, high-volume products for Fortune 100, mid-cap and start-up firms. Having previously helped manage the design of Apple’s PowerBook range, Howard went on to spend ten years at Amazon’s product development lab, where the Kindle, Fire TV and Echo were honed prior to launch.

“John has spent more than three decades leading teams dedicated to building and evolving complex platforms so that they meet both today’s and tomorrow’s needs,” explained Terem. “His creative thinking and extensive innovation skills are just what Markforged needs as we accelerate our product roadmap and enable our customers to print whatever they imagine at the point of need.”

Within its sales team, Metal PBF system manufacturer Additive Industries has hired Dave Emmett as its new Director of Sales and Business Development for North America. Emmett will be charged with driving strategic client relationships, building the firm’s North American sales team, and developing initiatives that help grow its share of the aviation, aerospace, defense, energy and industrial markets.

Over a 25-year management career, Emmett has held positions at Renishaw, GE Additive and BAE Systems, thus he brings significant industry experience to the role. Additive Industries’ latest addition to its leadership team is set to formally introduce himself at Rapid + TCT 2021, where he plans to hold ‘meet & greets’ from September 13-15 2021.

Ohio-based medical 3D printing firm Tangible Solutions has announced the appointment of Andy Blankemeier as its new Director of Sales. Effective from August 2021, Blankemeier will become responsible for driving the firm’s client relationships moving forwards, as well as developing its sales strategy for addressing the wider orthopedic implant market.

Prior to joining Tangible Solutions, Blankemeier was most recently a Business Development Manager at Global Equipment Services (GES), where he built long-standing relationships with medical device OEMs, and he has also held previous roles in the medical industry at Zeiss Microscopy, AMETEK Inc and the Invivo Corporation, Carl Zeiss Microscopy.

“Working with medical device OEMs to build the highest quality and safest devices for patient care is where I believe I can have the most impact,” said Blankemeier. “This work is bigger than myself; and I feel the passion of the OEMs for what they are doing to help others through the creation of life changing/saving devices.”

“The people at these companies truly care for the patients they are helping and they really live it—something I try to emulate every day.”

At construction 3D printing start-up Black Buffalo 3D, meanwhile, the company has unveiled Dr. Babak Zareiyan as its new Global Head of Research and Development. Leveraging his large-scale printing experience of more than ten years, Zareiyan will now work to further develop and commercialize the firm’s novel eco-friendly manufacturing approach.

“Our goal is to gain acceptance of concrete 3D printing among construction industry veterans to showcase what is possible with this impressive new technology,” said Michael Woods, CEO of Black Buffalo 3D. “Babak is an industry veteran with hands-on experience and an impressive portfolio of published academic whitepapers about construction 3D printing, robotics and automation.”

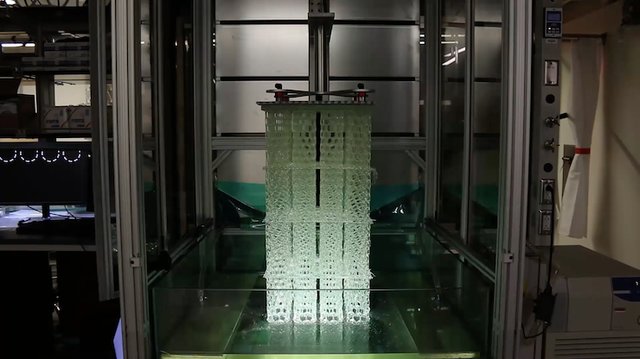

Finally, in terms of appointments, Illinois-based 3D printer manufacturer Azul 3D has announced that its VP of Product Development and Manufacturing, Cody Petersen, has been promoted to the position of CEO. Alongside Petersen’s promotion, the company has also appointed Co-founders David Walker and James Hedrick, as its new CTO and Chief Product and Business Development Officer respectively.

The moves closely follow Azul 3D’s hiring of industry veteran Tuan TranPham as its new CRO, amid a wider reshuffle as the company reportedly prepares to “launch new partnerships and products, grow its team and take on new challenges.”

“Solidifying this team is the next step in preparing for an exciting phase of rapid growth,” explained Azul 3D Co-founder and Chair Chad A. Mirkin. “Our HARP technology is poised to transform advanced manufacturing across industries, and we have the best team in place to guide this transformation.”

Facility openings and expansion updates

Kicking-off with expansions, inkjet printhead supplier Xaar PLC, has announced the opening of a new Customer Service Centre in Shenzhen. Under the leadership of the firm’s Asia GM Samuel Tam, the complex is set to provide support to its growing Chinese OEM customer base, in addition to widening Xaar’s existing global network.

The facility will also act as a hub for training customers, building client relationships and enabling the company to respond rapidly to their needs, while providing it with a means of better addressing the Chinese market with its ImagineX platform.

3D printing and machine tool manufacturing firm Matsuura Machinery has announced plans to expand its Leicestershire HQ, which will serve to significantly increase its capacity. Set to be built on land directly opposite to its existing base, the company’s new 11,500 sq. ft complex will be refurbished over the next two years, to feature a showroom, office space, storage areas and loading dock.

“This investment is the culmination of our success in supplying automated CNC machine tool solutions to an expanding UK customer base, and reflects our phenomenal growth in AM,” said Roger Howkins, MD of Matsuura Machinery. “This expansion is a demonstrative sign of our confidence in UK manufacturing, and reflects the current pressure we have for more operational capacity.”

Up in Scotland, the University of Strathclyde’s Advanced Forming Research Centre (AFRC) has also announced its intention to open a new office in Sheffield. Operating out of the city’s Olympic Legacy Park, the facility will provide South Yorkshire companies with improved access to advanced metallurgy technologies, numerical and analytical modelling tools and industrial forging and forming equipment.

As the AFRC’s first office outside of Scotland, the facility marks an important stage within its mission to help small UK businesses compete on the global stage, and should help it build close relationships with the nation’s forging community, ahead of the launch of FutureForge, an upcoming £20 million hot forging platform.

In the United States, meanwhile, Stratasys subsidiary Stratasys Direct Manufacturing has unveiled a new PolyJet Design and Print Center at its base in Eden Prairie, Minnesota. Built to centralize the firm’s production capacity and expertise into one location, the facility houses no fewer than sixteen PolyJet 3D printers, including two J55 Prime machines.

Alongside the opening of its new complex, Stratasys Direct has also launched a multicolor workflow that’s designed to allow its clients to streamline their design-to-print processes. In combination with its Design and Print Center, the firm anticipates that its customers will now be able to translate their ideas from concept to reality more quickly, by creating complex multi-color parts in a single 3MF file format.

“We see a growing customer demand for PolyJet 3D printing and we’re already observing strong interest in these expanded capabilities,” said Rich Garrity, President of Stratasys Americas. “Whether customers use us for a single project to supplement their AM capabilities, or as their sole provider of 3D printed parts, Stratasys Direct has the expertise and facilities to support their needs.”

Finishing this week with Forward AM, the BASF subsidiary has collaborated with design firm Xuberance to open an Additive Manufacturing Technical Center (AMTC) in Shanghai. The new facility is designed to act as a 3D printing hub for Asia-based customers, that brings together Forward AM’s hardware and engineering expertise, and Xuberance’s specialist design know-how.

Based in Shanghai’s Lingang Songjiang Science Park, the facility houses more than twenty SLS, FDM and other photopolymer 3D printers, and using this added capacity, Forward AM anticipates being able to not only provide enhanced technical services, but engage in joint innovation with customers across the Asia-Pacific region.

“For us, Forward AM’s cutting-edge materials and comprehensive industrial expertise, especially in simulation and surface finishing, ideally complement our expertise in services and design offerings,” said Leirah Wang, MD of Xuberance. “We are proud to jointly develop integrated and innovative solutions for additive manufacturing, tailored to customer needs in the Asia-Pacific region.”

The nominations for the 2021 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D Printing Industry Jobs Board. Image by 3D Printing Industry.