Welcome to the latest edition of our 3D printing jobs and career moves update for the additive manufacturing sector. If you are looking for a new position in the industry, we keep our 3D Printing job board updated with the latest positions.

You can easily apply to any of the posted jobs after creating a free profile. If you are just about to enter the sector, we offer a guide on how to get a job in the 3D printing industry.

The 3D Printing Industry jobs board is also free to use for employers to find 3D printing experts for their businesses.

Read on for career updates at 3YOURMIND, Desktop Metal and Launcher, job opportunities at Kymera International and expansions at 6K Additive, 9T Labs, Duravent, Eplus3D, Agnikul, Collins Aerospace, NYCU, Ozarks Technical Community College and more.

R&D Engineer at Kymera International (SCM Metal Products)

Specialty material developer Kymera International is recruiting for an R&D Engineer to work at its facility in Durham, North Carolina. Working as part of its New Product Development team, the successful candidate will be responsible for supporting the firm’s R&D of new aluminum and copper alloys via performance testing, metallurgical lab activities, atomization trials, test setup and gear maintenance.

As well as carrying out design of experiments using a variety of powders and processes to collect data, applicants will be expected to interpret results, summarize them and report findings in accordance with industry standards. The position also requires engineers to assist with technical service issues as they emerge, and ensure the smooth operation of assigned lab equipment by dealing with ad-hoc repairs.

In order to excel in this role, the company says that a Bachelor’s or Master’s degree like materials science or mechanical engineering is considered essential. Experience in powder synthesis and characterization, material processing, computational simulation and modeling or in industrial lab settings is advantageous.

More information about the role of R&D Engineer at Kymera International can be found via the 3D Printing Industry jobs site.

Leadership changes at Desktop Metal, Launcher and 3YOURMIND

In one of three leadership changes covered in this week’s update, 3D printer manufacturer Desktop Metal has revealed that its CFO James Haley is leaving his current role. Reportedly departing to pursue other opportunities, Haley is set to stay on as CFO until December 31, 2022, to ensure a smooth transition to life under his replacement, and he will also serve as an advisor for a period after he steps down.

“It’s been an honor to be a part of Desktop Metal’s team and I’m proud of what we’ve accomplished in a period of rapid growth,” said Haley. “The company has never been stronger and given our tremendous portfolio, momentum of the business and strong financial position, now felt like the right time to transition to the next chapter in my personal and professional life. I want to express my respect and appreciation for the many talented individuals I’m grateful to have worked with.”

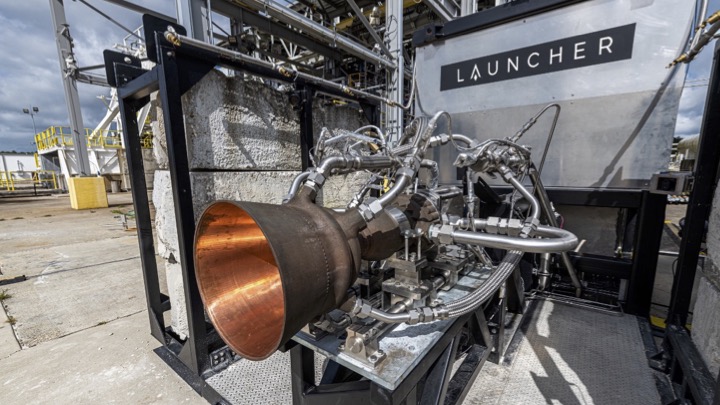

Private US aerospace firm Launcher has also announced a change at the head of its financial operations, with Sam Francis being hired as its new CFO. On the move, Francis, who brings over 25 years’ leadership experience to the role, has said that he’s excited to join the company, and help “grow its investor base and build up its financial operations” ahead of its first Orbiter flight in November 2022.

Lastly in appointments, 3D printing software developer 3YOURMIND has made Bas de Jong its COO and MD, in a move that sees him replace departing Co-founder Stephan Kühr in the former, and step into the position from his current role as CCO.

Having spent more than eight years in the industry, during which he has helped build up 3D printer manufacturer Ultimaker, de Jong will now oversee the company’s strategic and day-to-day operations. Working directly under 3YOURMIND CEO Aleksander Ciszek, the new COO will reportedly attempt to use his customer-centric approach, to advance the firm’s software adoption in on-demand production.

“3YOURMIND continues to push boundaries in additive manufacturing software,” said de Jong. “We solve the biggest problems in our industry: identifying and qualifying the right applications to demonstrate and realize the value of AM. It is very exciting to work with such a great team of dedicated people and help our customers scale 3D printing.”

Expansions at 6K, 9T Labs and more

Moving onto facility news, 6K Additive, the 3D printing division of material developer 6K, has announced the expansion of its commercial operations into Europe. The move, which has seen it appoint François Bonjour as its European Sales Director, will allow the firm to address rising interest in its powders there from EU clients and system manufacturers.

François joins 6K Additive having spent over ten years working in the metal powder and alloys markets with companies like the Powder Alloy Corporation, Tekna Plasma System and TIG, at which he was responsible for European sales and business development. He also spent eight years at ThyssenKrupp, where he worked with aerospace firms like GE Aviation, Airbus and Safran, amongst others.

“Over the last two years, we’ve established 6K Additive in North America as the go-to organization for high-quality AM powder with environmental and sustainable benefits,” said 6K Additive President Frank Roberts. “We’re excited to bring our powders to the European market where a high value is placed on technologies that can contribute to the circular economy and meet their stringent quality metrics.”

Over in Switzerland, meanwhile, carbon fiber 3D printing specialist 9T Labs has unveiled plans to open its first office in the US. Set to be funded via 9TLabs’ $17 million funding round, which closed earlier this year, the Boston facility is designed to serve as a meeting point for the country’s newest innovators in structural composites. Plans for the facility are said to be moving ahead at pace, with the first US team members expected to be hired and sent for training in the coming weeks.

“We are very excited to start this next step for the company,” said Martin Eichenhofer, CEO of 9T Labs. “Our team is confident of a strong impact on the American markets by our latest innovations in advanced composite additive manufacturing, and we look forward to working with US investors and expanding our reach to customers.”

Heating, ventilation and air conditioning specialist Duravent has opened a $1 million facility in West Michigan, complete with a technology lab and 3D printing capabilities. The move follows Duravent’s acquisition of Hart & Cooley in 2021, whose HQ became too large when its workforce shifted to remote and hybrid work during the pandemic, hence the firm has now consolidated via its new innovation center.

“We felt that we needed a facility that better represented the future of our company in terms of innovation, growth and leadership,” Duravent CEO Simon Davis told the Grand Rapids Business Journal. “As we branch out into the community, I think the growth we’re having and the way we’re going will be exciting, and we hope to continue to invest there.”

Chinese 3D printer manufacturer Eplus3D has also moved into a new home, albeit in its case a larger one than before. Featuring 23,000 m2 of working space, the facility is set to serve as the firm’s HQ moving forwards, and provide it with capacity for R&D, sales, marketing and technical applications, as well as a revamped showroom.

On the machinery front, the complex has been equipped with several Eplus3D systems, including the quad-laser EP-M650, large-volume EP-M450H and batch production-friendly EP-M300, plus other metal, SLS and SLA machines. In addition to the fulfillment of part production services, the base will also be used for demonstration, proof of concept development, consulting and training purposes.

Elsewhere, in the world of aerospace, Collins Aerospace has announced the opening of a new additive manufacturing center in Monroe, North Carolina. To start with, the facility has been fitted with just two 3D printers, but the company plans to add more in future. Moving forwards, the complex will be used alongside its other factories in the US and Poland, to support its development of next-gen aircraft.

“Through a process of joining materials layer upon layer to make parts from 3D model data, additive manufacturing offers several key benefits compared to traditional manufacturing,” said Kevin Myers, VP of Operations at Collins Aerospace. “By using additive manufacturing to produce aircraft parts and components, we can help reduce weight, cost and time to market, and provide more sustainable solutions for our customers.”

Aerospace start-up Agnikul has also opened India’s first 3D printed rocket-dedicated factory: ‘Rocket Factory – 1.’ Based at the IIT Madras Research Park, the complex is said to be packed with cutting-edge technologies, including a 400mm x 400mm x 400mm metal EOS 3D printer, that enable the end-to-end manufacturing of rocket engines.

The facility is reportedly designed to allow for the production of two ‘Agnilets’ per week, propulsion systems Agnikul is marketing as the world’s first single-piece 3D printed engines, which it successfully test-fired back in February 2021.

“This marks the beginning of a new phase – a phase where we step into scaling & production from R&D & testing,” commented Srinath Ravichandran, Co-founder and CEO of Agnikul. “I am immensely proud of our team and grateful for their zeal and commitment to translate our vision into reality.”

New AM campus facilities to open at OTC and NYCU

Finishing off this week’s round-up with the latest in on-campus 3D printing facilities, Ozarks Technical Community College (OTC) has revealed that its weeks away from finishing its Robert W. Plaster Center for Advanced Manufacturing.

Now said to be five weeks from completion, the $40 million facility at OTC’s Springfield campus will be the largest in its history. Once finished, the 120,000 square foot complex is expected to offer state-of-the-art training and education courses in robotics, fabrication, mechatronics, automation, drafting, design and 3D printing.

National Yang Ming Chiao Tung University (NYCU), meanwhile, has established the Institute of Industry-University Innovation, Taiwan’s first center for university-industry collaboration. At the facility, NYCU is working with seven major hi-tech companies including Taiwan Semiconductor Manufacturing and MediaTek. On the international research front, the institution is also working towards breakthroughs in fields such as semiconductors, biosensing and ceramic 3D printing.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D Printing Industry Jobs Board. Image via 3D Printing Industry.