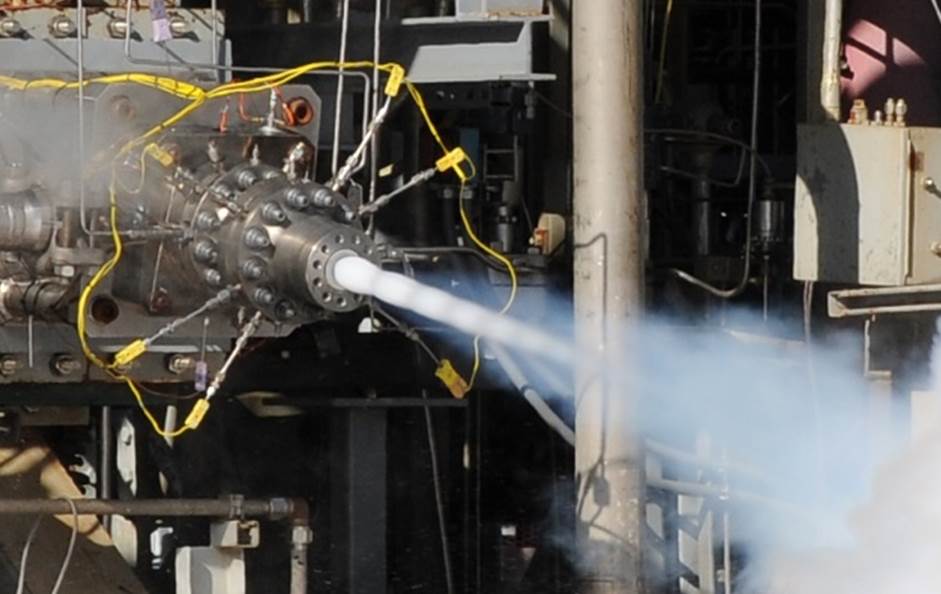

As a means of producing parts independent of Russian-based manufacturers, US defense and aerospace firm Aerojet Rocketdyne is currently working on a replacement for the Russian-made RD-180 engines used to power the Atlas V launch vehicle. A Space Act Agreement was recently signed between Aerojet Rocketdyne and NASA Stennis Space Center for test stand support and test services of the the company’s AR1 multi-element pre-burner and main injector. This new agreement will build on and solidify the relationship between AR and NASA’s Stennis Space Center, as currently Aerojet Rocketdyne’s two other engines are being tested at Stennis Space Center.

Julie Van Kleeck, Aerojet Rocketdyne vice president of Advanced Space & Launch says, “This is another example of Aerojet Rocketdyne’s focus to maintain schedule for the United States to be able to have AR1 ready to fly in 2019, to keep our country on track to end dependence on Russian engines.”

In order to meet the agreement, NASA Stennis will have to modify their E-1 complex, cell 1 test stand over six months in order to reconfigure it to conduct AR1 staged combustion testing. Van Kleeck adds, “We are using a stair step approach to eliminate the highest risk items first in our AR1 engine development program to ensure earliest possible delivery. By incorporating additive manufacturing and other new processes, materials and techniques into our plan, we offer the Nation a timely, cost-efficient path to end reliance on the Russian engines.”