Israeli electronics 3D printer manufacturer Nano Dimension has unveiled its latest machine, the DragonFly IV, alongside a supplementary ‘FLIGHT’ software platform.

As well as improving the traces, spacing, vias and outright quality of Printed Circuit Boards (PCBs), the firm’s new offering is said to simplify the creation of complex electronics into a “one-step” process. In fact, when used with its FLIGHT design program, the company says its upgraded system now offers users a “complete design-to-manufacturing” workflow, fit for “pushing the envelope” of PCBs.

“With the ability to leverage rapid and environmentally-friendly additive manufacturing processes, customers can change and metamorphose form, fit and function,” said Yoav Stern, Chairman and CEO of Nano Dimension. “The DragonFly IV will enable agile and rapid customization and personalization, as well as allowing for the innovative structuring of electronics in the third dimension.”

“Nano Dimension is bringing a completely new design and fabrication paradigm shift to the electronics industry.”

3D printing electronics at scale

Nano Dimension’s claims to be a “leader in Additively Manufactured Electronics” (AMEs) rely heavily on its proprietary Lights-Out Digital Manufacturing (LDM) technology. In essence, the firm’s approach allows users to deposit conductive silver nanoparticle and dielectric polymer inks simultaneously, as a means of creating multi-layered PCBs or advanced AME circuits within a single print job.

While the firm markets its electronic 3D printing technology in the shape of its DragonFly machines, they currently generate very little revenue, and brought in just $1.6 million during H1 2021. In an attempt to remedy this, Nano Dimension has now begun to spend some of the $1.5 billion funding it has raised since going public on Nasdaq in 2016, on businesses whose offerings could complement its own.

Earlier this year, for instance, the firm bought DeepCube for $70 million before acquiring Nanofabrica for over $50 million, in deals that have since allowed it to absorb teams with extensive machine learning and microprinting expertise.

Nano Dimension has also sought to drive sales by advancing its technologies and exploring new applications for them. This has led the company to work with the likes of Fraunhofer IPA, to develop a novel freeform electronics 3D printing and assembly approach, as well as the University of Technology Sydney, to fabricate enhanced 5G antenna arrays.

As part of a similar program, Nano Dimension has paired up with long-term partner Hensoldt as well, to form a joint venture called ‘J.A.M.E.S.’ Designed to act as a design community for exchanging best practises surrounding the production and integration of AMEs, J.A.M.E.S is now said to have served as an ideal test bed for the new DragonFly too, with the system making PCBs much easier to make than before.

A FLIGHT-enabled DragonFly

Marketed as a ‘Dielectric & Conductive Materials AM System,’ Nano Dimension’s long awaited DragonFly IV 3D printer is built from the ground up to enable the fabrication of high-performance electronics. Impressively, the machine is said to be capable of depositing materials while simultaneously integrating in-situ capacitors, antennas, coils and transformers, in addition to a range of other electromechanical parts.

Compared to the firm’s previous machines, the DragonFly IV is also able to create electronics with greater conductive predictability, as well as at higher quantities and more precise levels of detail, including those that incorporate HDI-level elements and traces down to a size of just 75µm.

To make turning ECAD designs into practical 3D printable products as easy as possible, Nano Dimension has launched its latest system in tandem with its new FLIGHT software. Complete with intelligent verification, slicing and job control functionalities, the program enables the 3D modelling of sophisticated parts, while ensuring that users’ designs comply with the system’s processing requirements.

In practise, the software suite is said to go through three stages: Plan, Check and Control, with the former designed to import and edit existing ECAD models, before checking their viability. Once given the all clear, these parts undergo DragonFly-specific design rule checks that shorten users’ iteration cycles, then finally enter a process whereby 2D and 3D electronics can be created at the same time.

Although Nano Dimension now plans to publicly debut the DragonFly at the Productronica event, it has already beta tested the machine as part of its joint initiative with Hensoldt, where J.A.M.E.S’ CEO Andreas Muller says it has allowed engineers to shake up their workflow, thus he labels it a “milestone in the evolution of AME technology.”

“Nano Dimension’s latest system, combined with the new FLIGHT software, enables the completion of complex jobs like no other AME system before,” said Andreas Muller, CEO of J.A.M.E.S. “The J.A.M.E.S electronic design engineers’ community will greatly benefit from better access to AME solutions, and the first-of-a-kind collaboration of ECAD/MCAD 3D design and testing.”

Technical specifications and pricing

Below are the technical specifications for the Dragonfly IV 3D printer. Ahead of the machine’s launch at Productronica, which is set to take place from November 16-19 2021, Nano Dimension has kept its aesthetics under-wraps, but those interested can now find out more and request a quote via the firm’s product page.

| Build Volume | 160 mm x 160 mm x 3 mm |

| Resolution | 18 µm (x), 18 µm (y), 10 µm (z) |

| Min. Line / Space | 75 μm traces / 100 μm spacing |

| Min. Conductive Layer Thickness | 1.18 μm |

| Conductivity (Relative to Copper) | 30 % + /-5 % |

| Supported File Formats | ECAD, MCAD, ODB++, G&E, STL |

| Dimensions | 1,400 mm x 800 mm x 1,800 mm |

| Weight | 520kg |

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

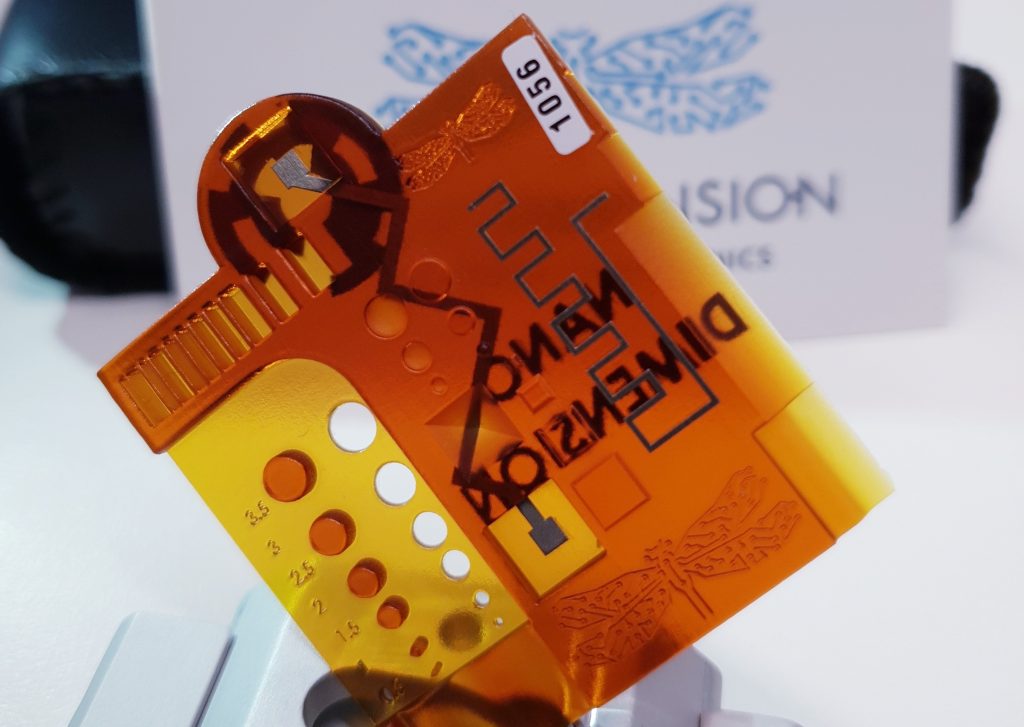

Featured image shows an additive manufactured electronic (AME) sample produced using one of Nano Dimension’s existing DragonFly machines.