The 2021 3D Printing Industry Awards shortlists are open for voting, have your say now.

The ProtoSpace of University of Technology Sydney (UTS) and Nano Dimension, a leading manufacturer of industrial 3D printers for additively manufactured electronics (AMEs) have carried out a pilot project to accelerate the development of 5G AME devices.

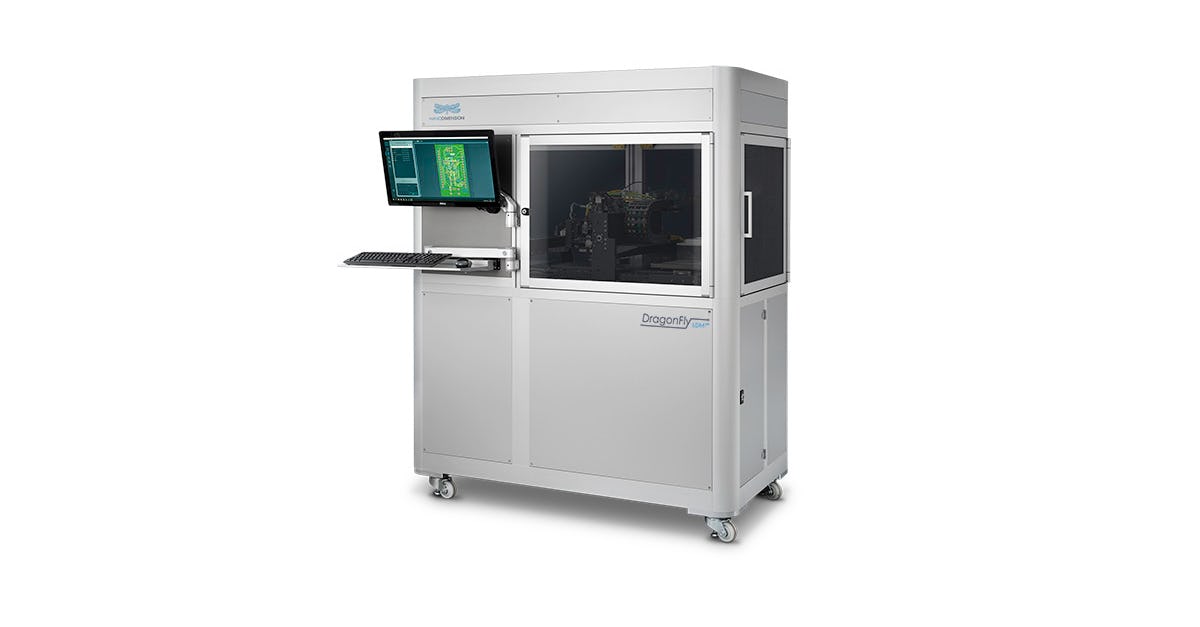

Using Nano Dimension’s DragonFly LDM 3D printing system, the partners fabricated 5G millimeter-wave antenna-in-package (AiP) designs that reportedly deliver enhanced bandwidth while bridging the gap between AME AiP and chips.

According to the partners, the successful printing of the prototype antenna arrays opens up “huge possibilities” for 5G consumer mobile electronics.

The DragonFly LDM 3D printer

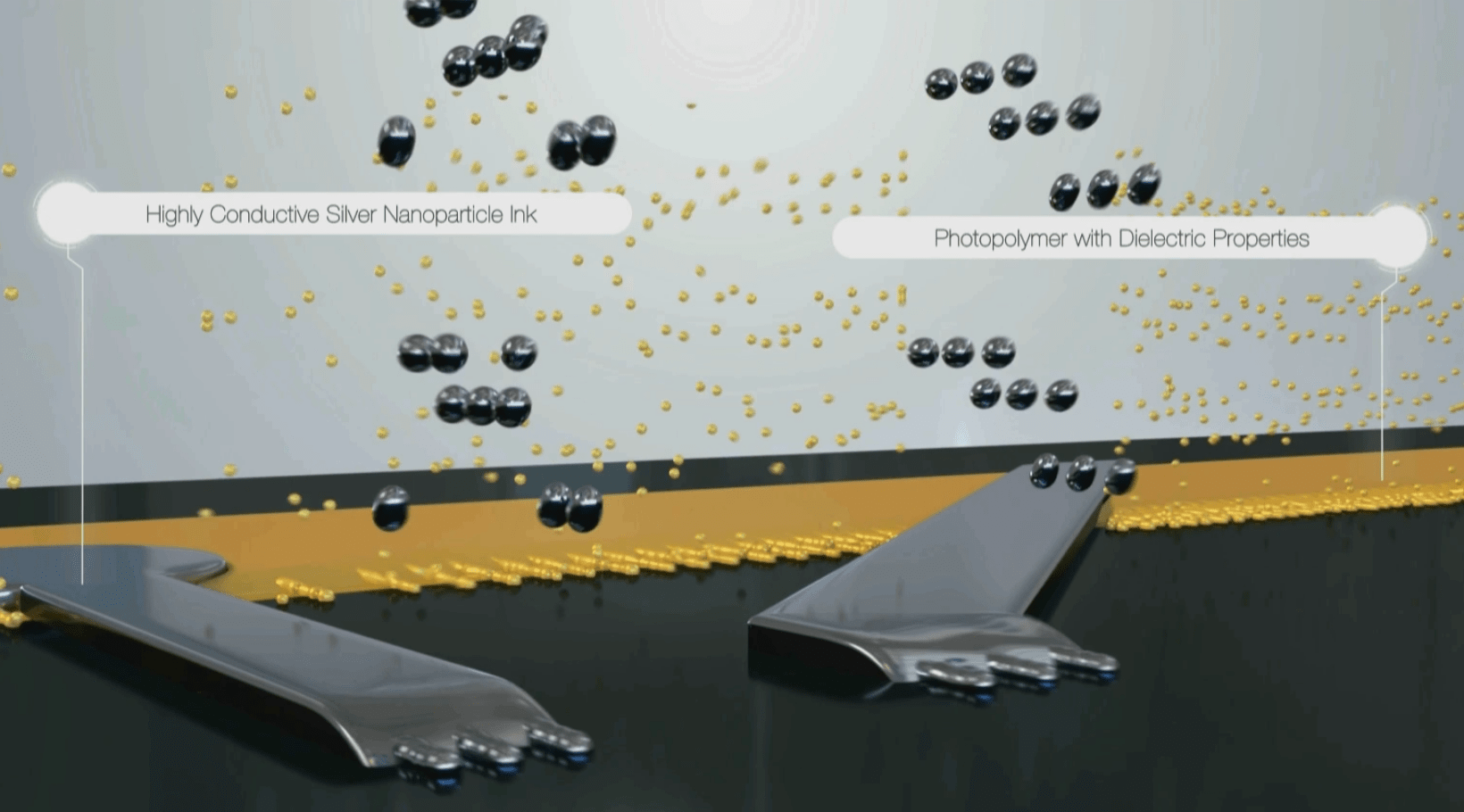

Nano Dimension’s flagship DragonFly LDM system is the driving force behind the firm’s AME capabilities, combining freeform geometrics with embedded electronics. The printer is equipped with two inkjet printheads that simultaneously print conductive silver nano-inks, which form the majority of the printed circuit’s connections, with dielectric photopolymer inks, which provide mechanical support, thermal resistance, and electrical insulation to the surrounding structures.

In April, Nano Dimension acquired machine learning firm DeepCube, and has since applied the firm’s deep learning expertise to develop a machine learning-based Distributed Electronic Fabrication network. The platform enables digital control over the company’s global network of 3D printers, which are able to continually self-learn and improve their efficiencies.

Shortly after, Nano Dimension also acquired microscale 3D printer developer Nanofabrica and has integrated the firm’s technology into its machines to further advance the 3D printing of precision high-performance electronic devices (Hi-PEDs).

With these acquisitions, Nano Dimension is seeking to tackle the ongoing semiconductor chip shortage being faced worldwide as a result of supply chain issues and increasing margin pressures on printed circuit board (PCB) manufacturers.

Most recently, Nano Dimension announced a partnership with the Fraunhofer Institute for Manufacturing Engineering and Automation (Fraunhofer IPA) to develop new freeform 3D printing and assembly processes specifically for the production of electromechanical systems. By the end of the two-year project, Nano Dimension hopes to integrate the processes into its DragonFly LDM system.

Advancing precision electronic components

Situated in the heart of Sydney, ProtoSpace UTS is one of Australia’s most advanced additive manufacturing facilities, providing access to advanced 3D printing and scanning technologies.

The pilot project between ProtoSpace UTS and Nano Dimension was led by Dr. Yang Yang, the group leader of Millimeter-Wave Integrated Circuits and Antennas at UTS’ Tech Lab. Yang has worked with Professor Francesca Lacopi and Nano Dimension’s R&D team to advance 3D printed millimeter-wave and terahertz antennas and circuits and harness the power of 5G for the space sector.

The partners have been working on a wireless ecosystem that will enable billions of high-speed wireless devices and highly-integrated AME device antennas operating at millimeter-wave bands to be packaged on mobile devices.

To achieve this, though, they still face several challenges before they can open up a “new era of 5G IoT”. The development of 5G AME devices is still in its infancy, due to the high cost and long production cycles for millimeter-wave AiPs making customized prototyping and proof-of-concept difficult.

Additionally, there remains an urgent need for high-speed steerable multi-beam mobile antennas within digital environments, now that the gains from conventional device antennas have been stretched to their limits.

The team is also tasked with investigating how to best integrate and miniaturize packaged antenna arrays without impacting their critical performance.

To address these issues, Yang and his team developed a novel AME process for producing 5G millimeter-wave AiP designs based on a proof-of-concept from a pilot project carried out by UTS and Nano Dimension. The process reportedly fabricates single-substrate multiple conductive layers with customized package profiles, without risking confidentially or IP security.

Fabricating the antenna arrays

Using the DragonFly LDM, the team produced several single-substrate multi-metal layer antennas using their developed AME process, which is based on piezoelectric 3D printing. Metal layers were vertically stacked into a 3D printed single substrate to form an antenna prototype that exhibited the advantages of wide bandwidth and ultra-low profile.

To prove their concept, the team designed and 3D printed multi-layer linear polarization (LP) patch antenna elements and 2×2 LP antenna arrays. The so-called ‘feeding network’ could be integrated into the same substrate of the antenna array element without increasing the size and profile of the array.

When compared with a traditional single-layer LP patch antenna, the team’s device improved the impedance bandwidth from 5.9 percent to 10.9 percent (three layers), and 83 percent (seven layers). The team’s designs can be manufactured in a single substrate with a thickness of just 1.5 mm, making it suitable for applications where ultra-low profile and wideband patch antenna are expected.

Following this, the partners produced circular polarization (CP) patch antenna elements and 2×2 CP antenna arrays, which validated the team’s vertical metal layer stacking method for obtaining wider impedance bandwidth and a broader frequency range of under 3-dB axial ratio. The antennas were designed at sub-6GHz, providing considerable potential for applications within 5G consumer mobile electronics.

The team believes its AME AiP technology is capable of seamlessly bridging the gap between AME AiP and chips, while delivering far cheaper prototyping costs than traditional manufacturing methods. They believe that these factors will aid in realizing initial proof-of-concept and customized prototyping for AME AiP, and therefore accelerate the development of 5G AME device antennas in industries such as space and consumer mobile electronics.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows Nano Dimension’s DragonFly LDM 3D printing technology in action. Photo via Nano Dimension.