Nano Dimension, a leading manufacturer of industrial 3D printers for additively manufactured electronics (AMEs), has announced a partnership with the Fraunhofer Institute for Manufacturing Engineering and Automation (Fraunhofer IPA).

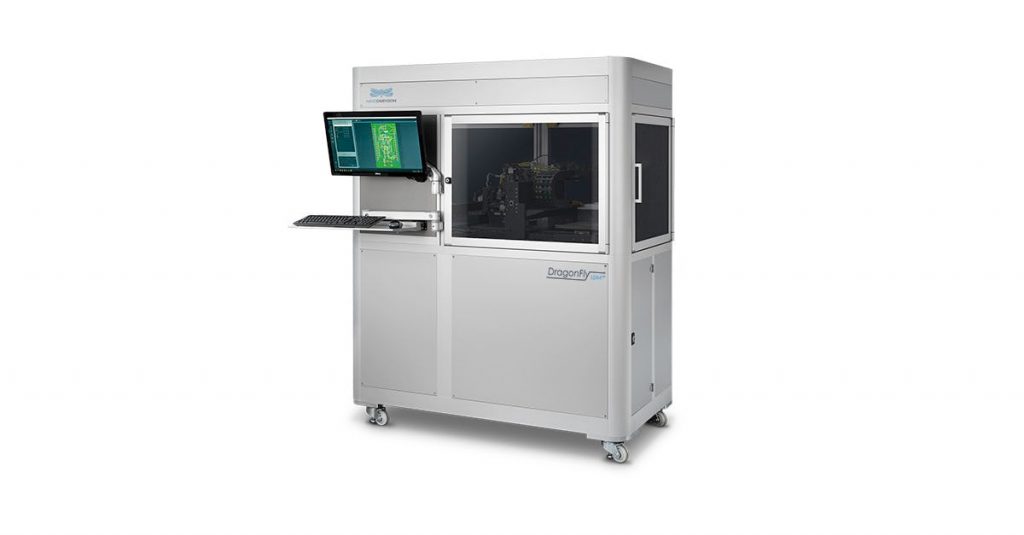

Under the two-year agreement, the organizations will research and develop new freeform 3D printing and assembly processes specifically for the production of electromechanical systems. The hopes are that by the end of the project, Nano Dimension will be able to integrate the innovations into its proprietary DragonFly LDM 3D printing system, which is already specialized to fabricate electronics such as printed circuit boards (PCBs).

Oliver Refle, Head of the Additive Manufacturing Department at Fraunhofer IPA, said, “This brain trust will allow both parties to instantly analyze and improve processes by sharing ideas, data, and expertise, as we develop the next generation of 3D inkjet printing with the goal of creating new and better processes and integrations for the ultra-accurate printing of new high-performance electronic devices (Hi-PEDs).”

Advancing the DragonFly 3D printer

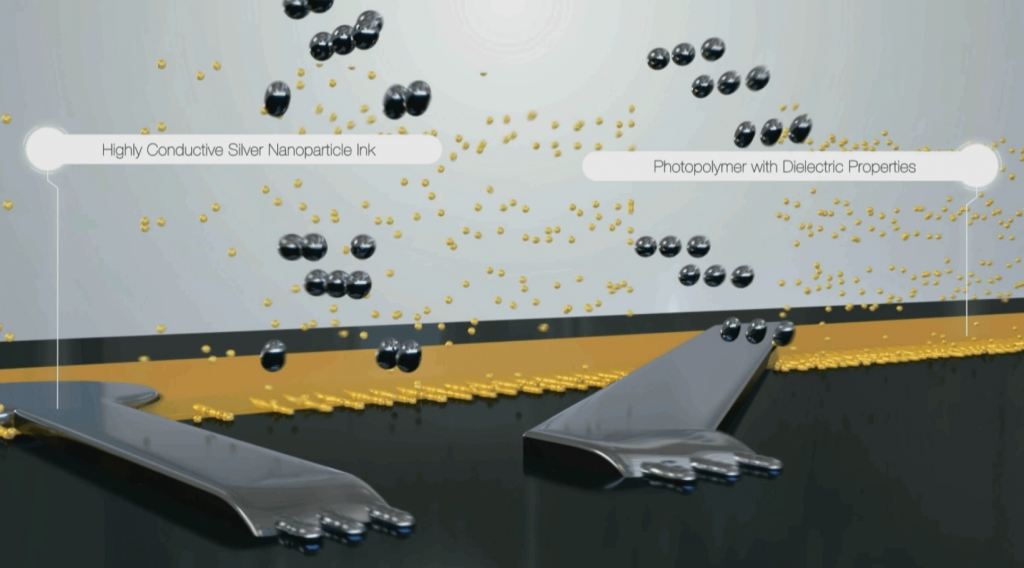

Nano Dimension’s flagship DragonFly LDM system combines freeform geometrics with embedded electronics. As the driving force behind the firm’s AME capabilities, it’s equipped with two inkjet printheads to simultaneously print conductive silver nano-inks with dielectric photopolymer inks. The silver inks are what make up the majority of the printed circuits’ connections, while the polymer inks are designed to provide mechanical support, thermal resistance, and electrical insulation for the surrounding structures.

The company’s AME fabrication technology is also capable of embedding in-situ electronic components into the printed parts. This includes capacitors, antennas, coils, transformers, and more. The resultant Hi-PEDs have applications in autonomous drones, cars, satellites, smartphones, and even implantable medical devices.

In April 2021, Nano Dimension acquired machine learning firm DeepCube. Nano Dimension has since used DeepCube’s deep learning expertise to develop an ML-based ‘Distributed Electronic Fabrication’ network, a platform for digital control over the company’s global web of 3D printers. Nano Dimension systems in the network are constantly self-learning and self-improving their efficiencies, maximizing yield for the company’s customers.

More recently, Nano Dimension also acquired microscale 3D printer developer Nanofabrica. The move will see Nanofabrica’s additive manufacturing technology integrated into Nano Dimension’s machines (which are microprinting systems themselves) to further advance the 3D printing of precision Hi-PEDs.

Refle adds, “Nano Dimension is a valued and trusted partner, and we are very excited to begin this new partnership.”

Combining expertise with Fraunhofer IPA

With roots dating back to 1949, the Fraunhofer-Gesellschaft has 75 research institutes operating under it in Germany. With over 29,000 employees, many of which are scientists and engineers, the organization works with an annual research budget of €2.8 billion.

Fraunhofer IPA, specifically, is concerned with technological R&D for the manufacturing sector. It even has a dedicated specialist department for additive manufacturing and has previously created a modular printing system that works with conductive and dielectric materials. With additional experience in developing pick and place processes, Fraunhofer IPA is a prime R&D partner for Nano Dimension to advance its AME platform.

Yoav Stern, Chairman and CEO of Nano Dimension, adds, “We are very pleased to have the opportunity to cooperate and learn from the world-class engineers and scientists at Fraunhofer IPA. We can learn from both their successes and failures while contributing our expertise and knowledge as we work together to build an eco-friendly and intelligent distributed network of additively manufacturing self-learning & self-improving machines.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the DragonFly 2020 Pro 3D printing PCBs. Photo via Nano Dimension.