Researchers from the University of Montreal have developed a new method of cell bioprinting based on a drop-on-demand technique.

Laser Induced Side Transfer, or LIST, utilizes a low energy nanosecond laser and the laws of microfluidic dynamics to jet living cells onto each other, additively stacking them to form larger droplets. The team of scientists believes their work can be adapted for grander applications such as 3D drug screening models and artificial tissues.

Challenges in 3D bioprinting

Bioprinting is one of the more attention-grabbing areas of 3D printing, but the reality of it can be quite disappointing. It’s very much in its infancy and the prospect of whole 3D printed transplant organs is still probably decades away.

Cell bioprinting, in particular, is concerned with building living constructs that display long term biological stability. There are currently a few different ways of doing this, each with their own challenges and limitations. Researchers have previously worked with microextrusion techniques (imagine a scaled-down FDM setup), but these often have troubles with bioink viscosity and cell placement precision.

Alternatively, a technique like Laser Induced Forward Transfer (LIFT) omits the nozzle entirely, instead of using a focused laser beam to propel a bioink film from a donor substrate to a receiving substrate. LIFT has garnered some success when 2D bioprinting, but extending it to the third dimension is met with hurdles like maintaining a thin and uniform film.

Laser Induced Side Transfer

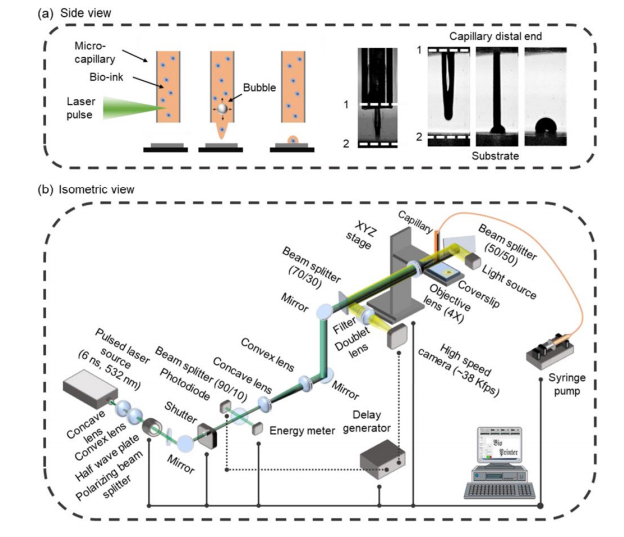

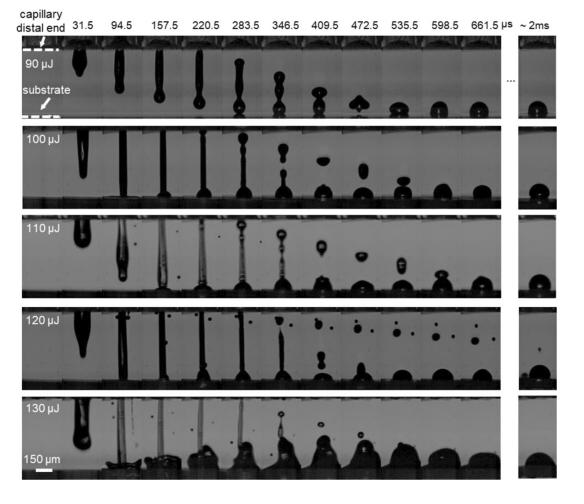

In LIST, a low energy laser with a wavelength of 532nm pulses, generating a transient microbubble at the far end of a glass microcapillary containing bioink. The expansion of the bubble ejects a microjet containing cells in a direction perpendicular to the laser (towards the opening of the capillary). Each pulse lasts exactly 6 nanoseconds and the energy of each pulse can be varied between 50 and 150μJ.

While experimenting with the energy of the laser, the team found that it had a major effect on the size of the deposited bioink droplets. Less energetic bioink jets were sometimes unable to penetrate the receiving substrate, instead of ricocheting back. In rare cases, with very high laser energies, bioink droplets as large as 325 microns were observed to be deposited.

The final stages of the study involved partially printing a human umbilical vein with the method (it was really just a few endothelial cells). The researchers determined virtually zero loss in cell viability and the printed culture maintained its ability to migrate, proliferate, and form new junctions between cells. In light of the results, the method shows great potential in 3D bioprinting tissue constructs with viscosities and sizes suitable for a clinical setting.

Further details of the study can be found in the paper titled ‘Drop-on-demand cell bioprinting via Laser Induced Side Transfer (LIST)’. It is co-authored by Hamid Ebrahimi Orimi, Sayadeh Sara Hosseini Kolkooh, Erika Hooker, Sivakumar Narayanswamy, Bruno Larrivée, and Christos Boutopoulos.

Bioprinting can be done with a vast range of materials for a number of different intended applications. A team of researchers from Nagoya City University, Japan, recently developed a new type of 3D bioprinted drug delivery system, leveraging fish gelatin. The gelatin, in this case, was used as the core component in a polymer hydrogel, which was used to fabricate an implantable patch loaded with an anticancer drug.

Elsewhere, at Tsinghua University, researchers recently 3D bioprinted brain-like tissue structures capable of nurturing neural cells. A group of primary neural cells from the cortex of a rat was integrated into the printed structure, with results suggesting that the cells had formed a complex neural circuit capable of responding to external stimuli.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows microjet evolutions at different laser energies. Image via the University of Montreal.