A team of researchers from Nagoya City University, Japan, has developed a new type of 3D bioprinted drug delivery system, leveraging fish gelatin. The gelatin is the core component of their newly developed polymer hydrogel, which can be used to fabricate an implantable patch. In this case, the team loaded the patch with PEGylated Liposomal Doxorubicin, a drug used for cancer treatment, citing great potential in localized nanomedicine delivery.

The cardiotoxicity of anticancer drugs

Anticancer drugs, such as doxorubicin (DOX), often exhibit serious and irreversible cardiotoxic effects when applied in their natural state. For this reason, biocompatible lipid capsules called liposomes are used as drug carriers, significantly reducing these cardiotoxic effects. Liposomes also have the effect of extending the drug’s circulation time in the bloodstream, allowing the active agents to accumulate in cancer tissue. This is what the PEGylated Liposomal Doxorubicin used in the study is – a liposome wrapped doxorubicin package typically used for breast cancer, bladder cancer, and leukemia.

The targeted local delivery of DOX is a much-researched topic and almost a field in and of itself. There are already a number of different ways currently used in medicine, including cast implants and injectable implants, but the Nagoya scientists saw the potential of 3D printing for the application.

Fish gelatin patches

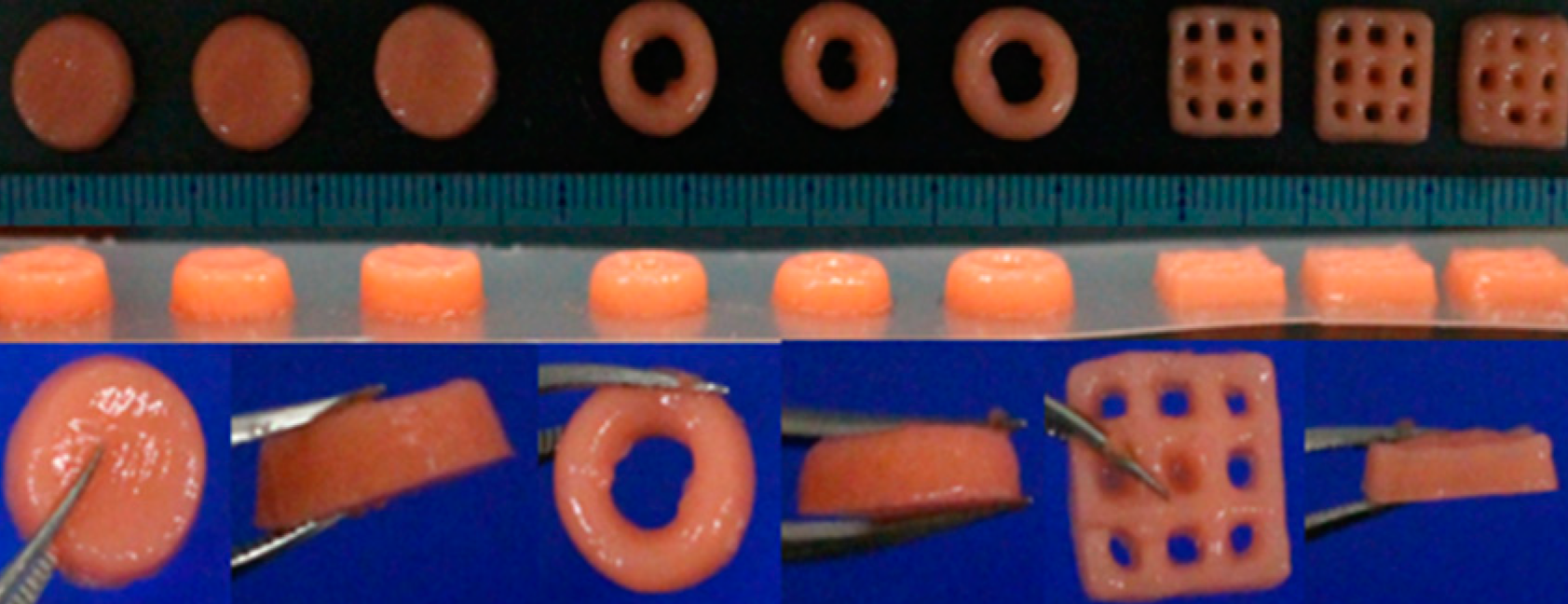

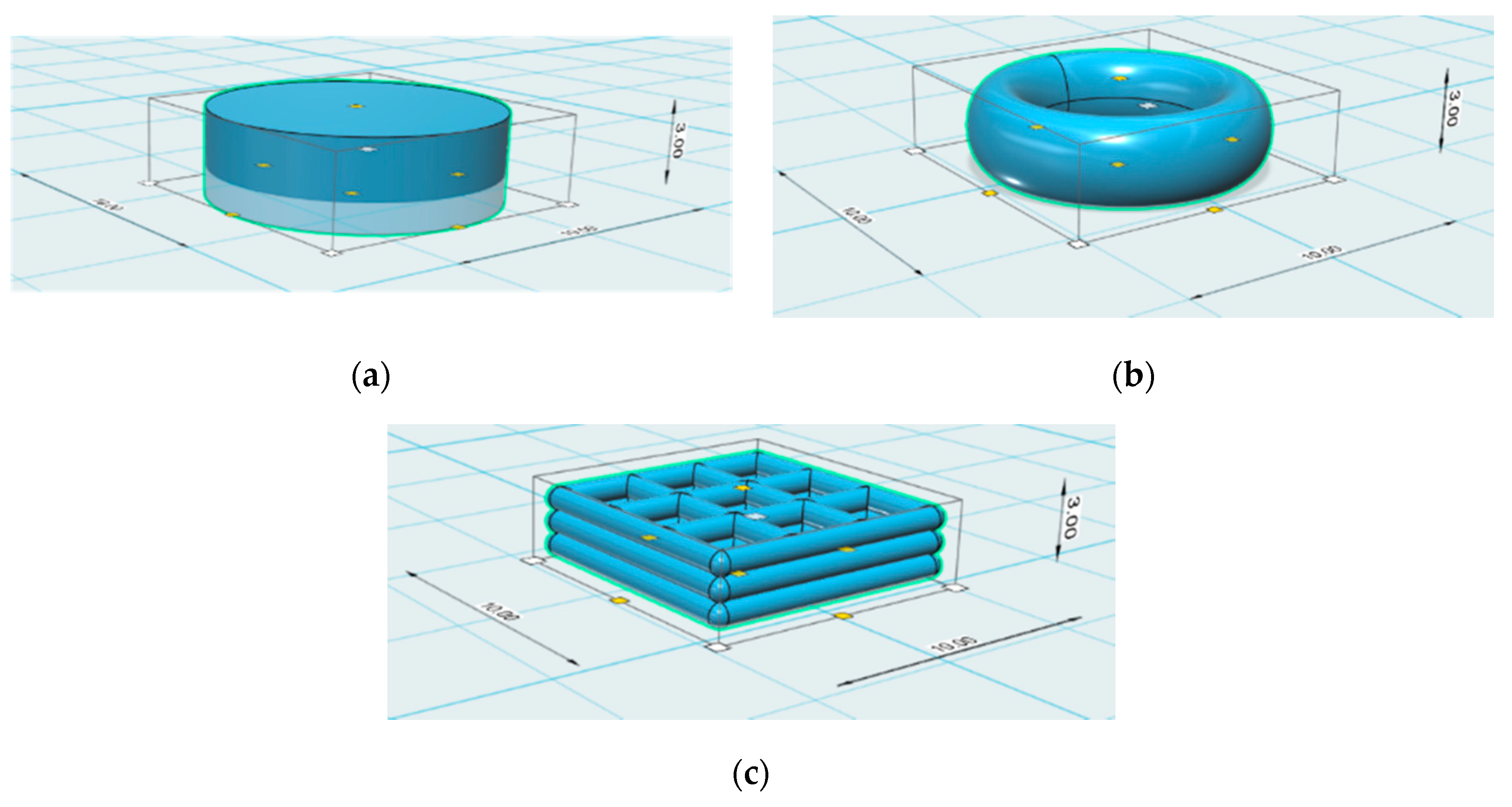

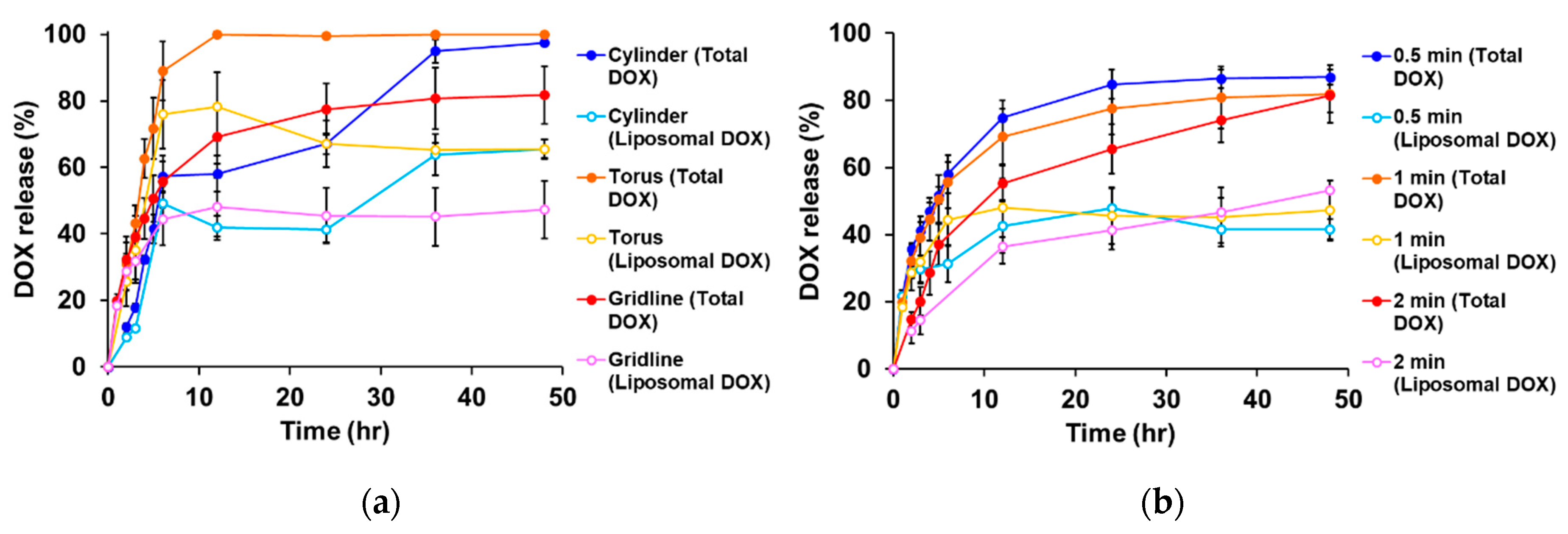

The team used a semi-solid extrusion type bioprinter to print three different patch shapes – a cylinder, a torus (donut), and gridlines. The hydrogel used contained a semi-synthetic polymer, with the main ingredient being fish gelatin. The choice of animal stemmed from the fact that fish gelatin is relatively cost-efficient and tends not to clash with any personal or religious beliefs. Once fabricated, the patches were loaded with the DOX compound and the team got to work on determining their release rates.

The release tests were done in vivo, and the results showed that the gridlines were most suitable for a sustained release device. Initially, the team ran into some problems with the extremely low viscosity of the gelatin, but this was remedied with the addition of carboxymethyl cellulose sodium, a pharmaceutical excipient.

Since the patches also had a photosensitive component to them, the researchers found that they could control the release rates with varying UV exposure times. Specifically, as UV exposure increased, the DOX release rate decreased and total DOX release capped at a lower percentage. The team concluded that their work could be used as a proof-of-concept, with further developments enabling the technique to be used in a clinical setting.

Further details of the study can be found in the paper titled ‘Fabrication of 3D-Printed Fish-Gelatin-Based Polymer Hydrogel Patches for Local Delivery of PEGylated Liposomal Doxorubicin’. It is co-authored by Jin Liu, Tatsuaki Tagami, and Tetsuya Ozeki.

The 3D printing of medical implants has really started taking off in recent years. Earlier this year, a team of researchers from Tsinghua University, Beijing, 3D printed a personalized cervix tissue implant to counteract human papillomavirus (HPV). By loading the porous structure of the polyurethane implant with an anti-HPV protein, the team was able to slowly release the protein and inhibit HPV growth at the site of infection.

Elsewhere, researchers successfully combated E. coli with a 3D printed multi-drug delivery device. The printed structure comprises a core and a shell, each able to hold a different drug and deliver it to a different section of the gastrointestinal system. The researchers believe their work could have extensive applications in probiotics.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D bioprinted patches. Photo via Nagoya City University.