Researchers from the Massachusetts Institute of Technology (MIT) have developed a new method of 3D printing objects that can sense user interaction.

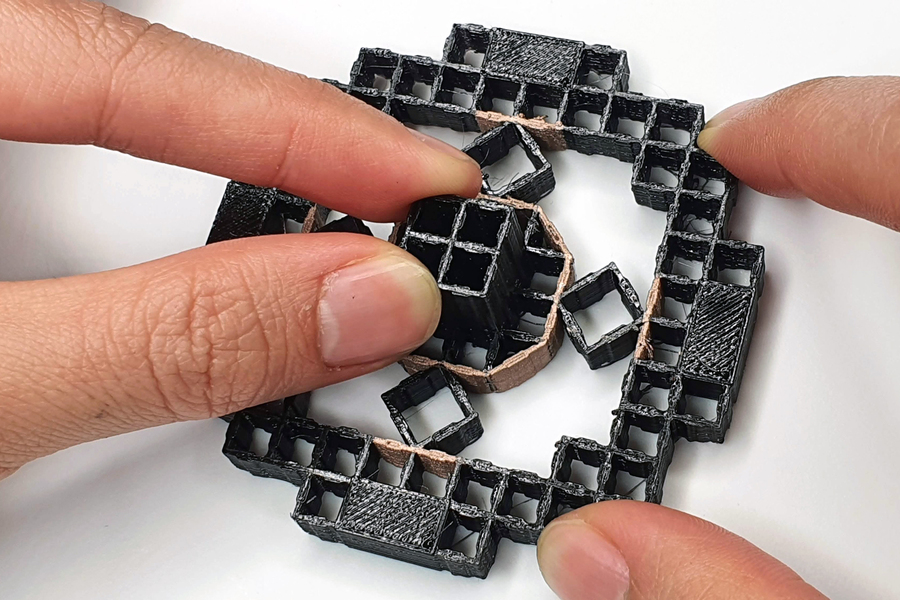

The novelty here is that the objects are 3D printed from a single piece of material (or metamaterial, more precisely), with electrode sensors integrated into the material structure itself. As such, the printed structures are able to detect various changes in state, including applied forces and rotations.

The team believes its approach could have applications in a whole host of custom input devices such as joysticks, switches, and handheld controllers. Taking it a step further, the sensing metamaterial can even be incorporated into more complex intelligent environments such as a couch capable of detecting the user’s body, which might collect data for posture correction analysis later on. Certain actions might even be mapped to functions like turning on a light or the TV.

Jun Gong, co-lead author of the study, said, “Metamaterials can support different mechanical functionalities. But if we create a metamaterial door handle, can we also know that the door handle is being rotated, and if so, by how many degrees? If you have special sensing requirements, our work enables you to customize a mechanism to meet your needs.”

How does the 3D printed metamaterial work?

The MIT metamaterial is made up of a grid of repeating cells, most of which are flexible, meaning they can extend and compress. It also contains ‘conductive shear cells’, which have two opposing walls made of a conductive filament and two walls made of a non-conductive filament. The conductive walls are what act as the sensing electrodes.

When a force is applied to the structure, the conductive shear cells either expand or compress, changing the distance between the conductive walls. Using capacitative sensing, these distance changes can be measured and mapped to certain forces, directions, rotations, and accelerations. For example, the movement of a joystick handle (and the subsequent flexures) might be mapped to left, right, up, and down.

A product designer could extend this idea to prototype a custom joystick shape for people with limited mobility or grip strength, or create a unique flexible music controller and connect it to a digital synthesizer. Since the metamaterial is designed for 3D printing, rapid design iterations would also be easy to produce, significantly streamlining the development cycle.

MetaSense, a 3D editor

To complement the 3D printing approach, the MIT team has also developed a purpose-built 3D editor called MetaSense. Intended as a CAD software for the metamaterial, MetaSense allows users to either manually place the conductive shear cells or automatically integrate sensing into the design in optimal locations.

Gong explains, “The tool will simulate how the object will be deformed when different forces are applied, and then use this simulated deformation to calculate which cells have the maximum distance change. The cells that change the most are the optimal candidates to be conductive shear cells.”

Although MetaSense is designed to be as simple as possible, the complex nature of the metamaterial requires a lot of parameter-tuning to complete a successful build. Gong’s team plans to continually improve the software’s algorithms to enable more sophisticated simulations, facilitating devices with hundreds or thousands of conductive shear cells.

Further details of the study can be found in the paper titled ‘MetaSense: Integrating Sensing Capabilities into Mechanical Metamaterial’. It is co-authored by Jun Gong, Stefanie Mueller, et al.

Additive manufacturing’s extensive material compatibility lends itself quite well to sensor device applications. Earlier this summer, scientists from South Korea’s Daegu Gyeongbuk Institute of Science and Technology (DGIST) developed low-cost multi-directional pressure sensors using 3D printed conductive polymer composites as their building blocks. The sensors are designed to overcome the current limitations of 3D printed sensors, which include the ability to only sense applied forces along a single direction.

Elsewhere, scientists based in Asia recently collaborated to develop a set of novel 3D printed sensors that could be used as a basis for the ‘smart beds’ of the future. Using an FDM 3D printer and PLA, the researchers managed to produce Fiber Bragg Grating (FBG)-based pressure sensors capable of tracking people’s sleeping patterns with a high degree of accuracy.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D printed metamaterial. Photo via MIT.