Scientists based in China, Pakistan and Hong Kong have collaborated to develop novel 3D printed sensors that could be used as a basis for the ‘smart beds’ of the future.

Using an FDM 3D printer and PLA feedstock, the researchers have managed to produce Fiber Bragg Grating (FBG)-based pressure sensors, capable of tracking people’s sleeping patterns with a high degree of accuracy. If applied within hospital settings, the team believe their devices have the potential to help staff monitor the wellbeing of patients, and intervene early-on if their condition deteriorates.

“Limited work has been done on 3D printed sensors to determine their benefits in use as a ‘smart bed’ or pad for monitoring sleeping patients,” said the researchers in their paper. “In [our] study, the FDM process was used to develop innovative FBG-based pressure sensors. The main advantages of these sensors include lightweighting, temperature insensitivity, and quick prototyping with low-cost, high-precision, EMI and time efficiency.”

FBG 3D printing-potential

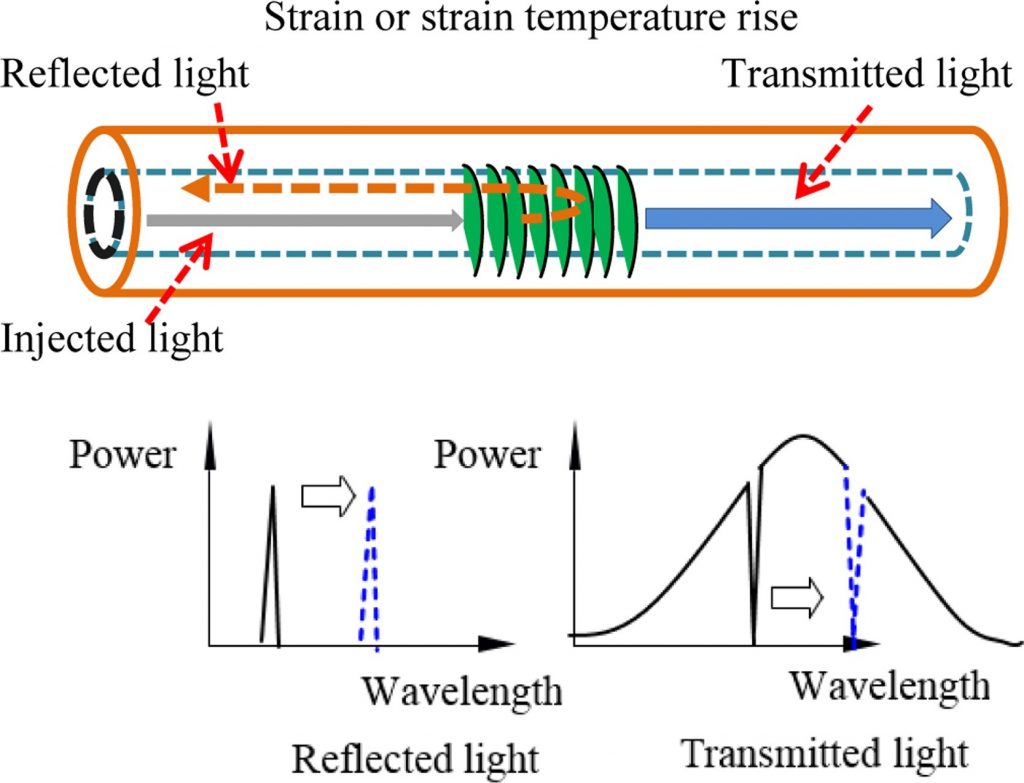

Generally, an FBG is a few millimeter-long microstructure inscribed into a short segment of optical fiber, that’s able to modulate any light passing through it in response to temperature, strain or vibrational stimuli. The high thermal sensitivity of such devices has lent them extensive mechanical engineering, textile and medical applications, but their efficacy is dependent on their material base.

In the past, healthcare-oriented FBG sensors have been fabricated using glues, ribbon or tapes and epoxy resin, yet the process remains time-consuming, equipment-intensive and difficult to replicate. 3D printing, by contrast, is increasingly enabling the creation of complex FBG sensing devices, but so far research has been limited to custom orthotics and little has gone into investigating their sleep-monitoring potential.

To put this right, the researchers used CATIA software to design a novel FBG sensor before sending it to Flash Print as a means of adjusting its level of infill, and eventually FDM 3D printing it. Interestingly, once half the device had been printed, the team paused production to place it at the center of a grooved semi-circle, in order to ensure that its sensor was properly sited and capable of strain resistance.

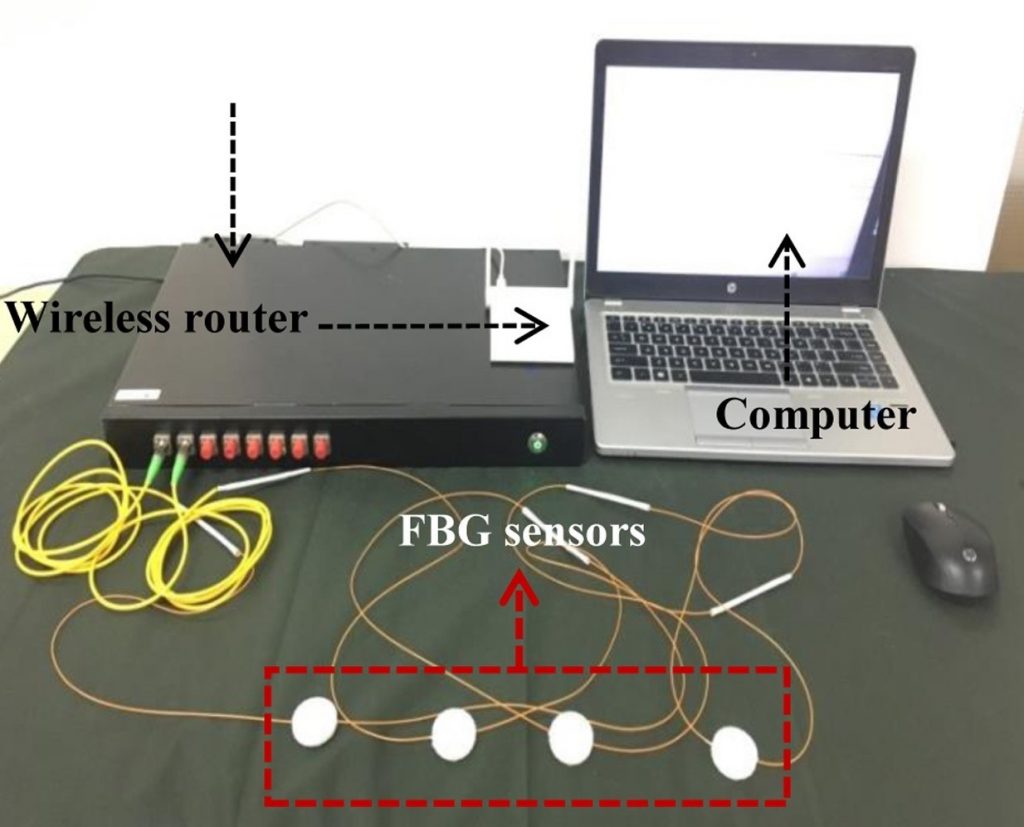

After finishing their prototype, the team were immediately able to detect signal variations from it using an interrogator and wireless router set-up, which correlated with its post-printing cooling times. To examine this relationship more closely, and investigate its bed-tracking potential, the scientists proceeded to fabricate three more devices, connect them up and subject them to calibration testing.

Assessing FBG sensors in bed

During initial evaluations, the team’s 3D printed sensors were placed into the moving jaws of a tensile tester, and put under incrementally-higher pressure loads of up to 352.8 N. Each device not only held up to six repeated test cycles, but showed a consistent wavelength change in every step, demonstrating their ability to provide reliable readings.

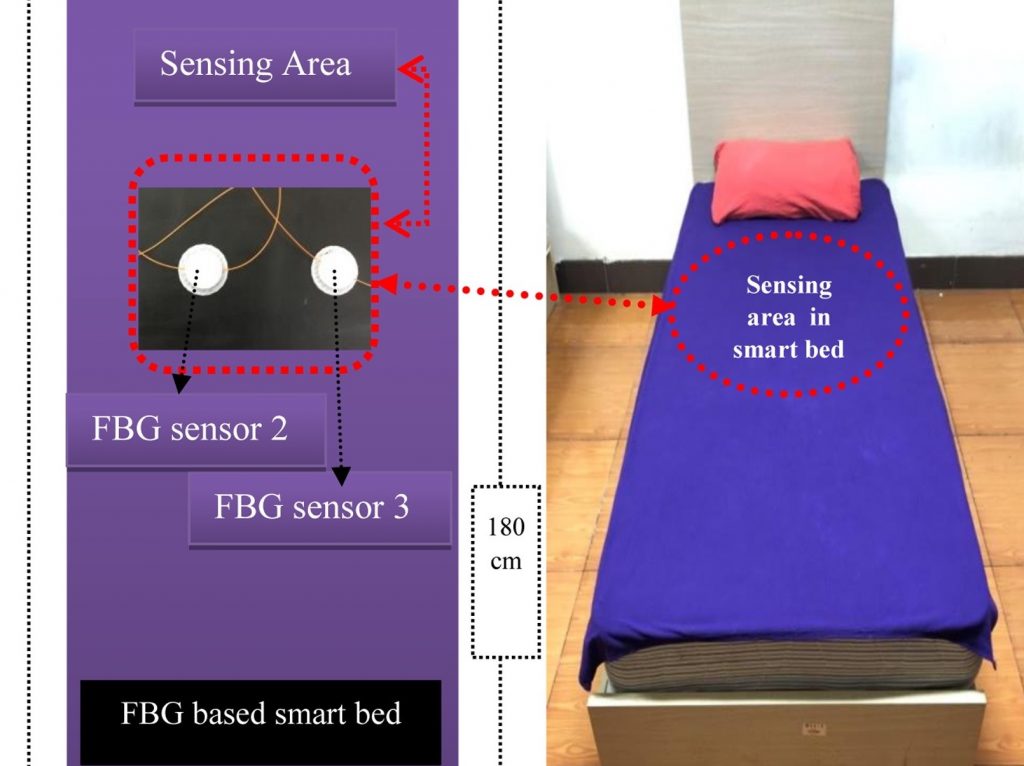

To assess the end-performance of their devices, the team identified and placed their two best-performing prototypes under the mattress of a bed 20 cm away from each other, before asking a 28-year-old volunteer to simulate the ‘starfish,’ ‘log-right and left’ and ‘free-faller’ sleeping positions on them, with the sensors tracking his changes in posture.

Results showed that as the test subject changed his body position, the sensors’ readings were consistently accurate, achieving a relative error rate of less than 1%. Consequently, although the team concede that their devices require further testing, they believe that in future, they could help doctors identify variations in a patient’s breathing, or even provide warning of when their heart rate has begun to fall.

“Testing indicated that FBG sensors sustain stable measurement performance during loading and unloading, and the fitted linear relationship showed that the measured wavelength change is directly proportional to the difference in applied load,” concluded the team in their paper. “The FBG pressure sensors-based smart bed can [therefore] be developed for monitoring patients in hospitals.”

Clinical 3D printed sensors

Over the last year alone, researchers have deployed 3D printing to produce a wide variety of different light, motion and bacteria-sensitive devices, with potential healthcare applications. Last November, scientists at Clarkson University used a custom bio-ink to create skin-friendly 3D printed biosensors, capable of protecting wearers from UV overexposure.

Similarly, Shanghai Institute of Technology researchers have developed a 3D printable conductive polymer hydrogel as a basis for producing flexible wearable motion sensors. In advanced testing, the team found that their devices’ mechanical and electroconductive properties made them ideal for soft robotics and wound dressing applications.

The CCDC Soldier Center, meanwhile, has taken a microfluidic approach to monitoring devices, developing unique skin-compatible multipurpose biosensors last year. Working alongside the University of Minnesota (UMN), the CCDC has managed to 3D print sensors with the potential to physiologically-track troops, and provide them with enhanced awareness of toxic airborne threats in the field.

The researchers’ findings are detailed in their paper titled “Development of FBG pressure sensors using FDM technique for monitoring sleeping postures.” The study was co-authored by Zamir Ahmed Abro, Chengyu Hong, Yifan Zhang, Muhammad Qasim Siddiqui, Abdul Malik Rehan Abbasi, Zafarullah Abrob and Syed Qutaba Bin Tariq.

Research was conducted collaboratively across Shenzhen University, Donghua University, BUITEMS and Hong Kong Polytechnic University.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the researchers’ detection set-up for their 3D printed bed sensors. Photo via the Sensors and Actuators A: Physical journal.