MIT Professional Education is launching a new course, “Advances in Computer-Aided Design for Manufacturing.” I asked the course instructors, MIT professors Wojciech Matusik and Justin Solomon, for some more details and about the 3D printing and design skills required for the future workplace.

The course takes place on MIT’s campus in Cambridge this June and will explore the wide use of emerging tools – such as additive manufacturing techniques that not only allow for new shapes represented within CAD systems to be created but also help organizations get from concept to design faster. It will also look at trends in 3D printing and new collaborative CAD that allows development and design in the cloud.

According to the MIT professors, “The manufacturing industry is undergoing a major transition.” Specifically, “Beyond making many copies of the same object, modern manufacturing is becoming digital and on-demand.”

Product prototyping is becoming easier and easier (and faster and faster): better software tools and new manufacturing methods like additive manufacturing are revolutionizing the way we approach product design. Engineers and designers must stay up-to-date with these concepts to keep their company at the technological cutting edge.

Cutting edge CAD concepts

The one week course will demonstrate state-of-the-art CAD systems, “including how the tools are built internally and how to use them in practice.” The organizers say participants will learn, “basic concepts as well as cutting-edge developments in the world of computer-aided design (CAD) as it is applied to digital manufacturing.”

During their time at MIT, “Attendees will become familiar with the entire CAD pipeline, from developing a concept to designing a three-dimensional surface or volume.”

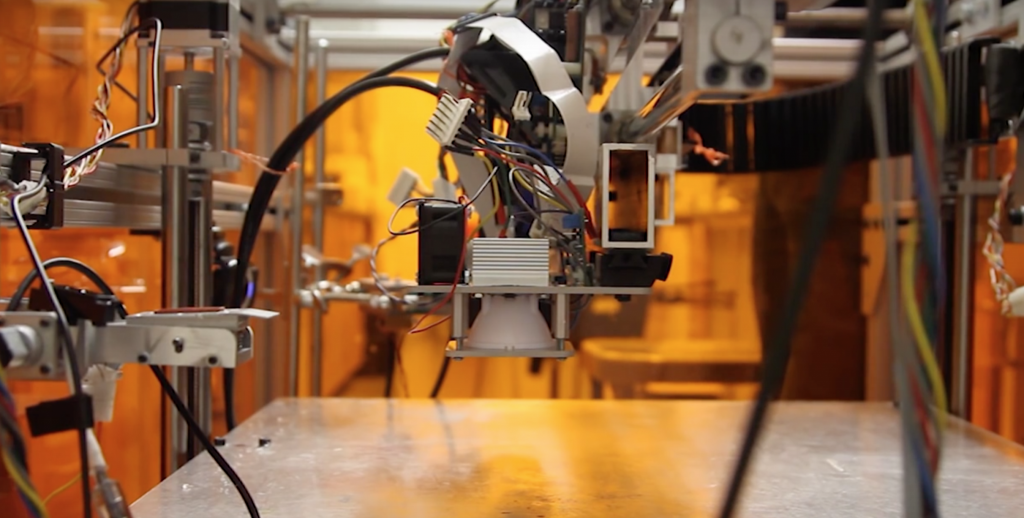

This process also highlights the virtual simulations of various materials, numerical optimizations for automatic design, and taking into account the considerations when interfacing with manufacturing hardware. Participants will have the chance to experiment with state-of-the-art CAD software through laboratory-style activities designed to exemplify common challenges when working with CAD software and to highlight potentially interesting components of the CAD pipeline.

Skills for the future

In context of skills for the future, the organizers explain that, “New tools and manufacturing methods have revolutionized the way we approach modern design and greatly changed the landscape of the computer-aided technologies that drive the design, engineering, and manufacturing processes.”

With this in mind the course, “offers engineers, developers and researchers the chance to experiment with state-of-the-art systems and learn how to apply them to help keep their companies at the technological cutting-edge.”

We don’t assume those taking the course know how to use CAD or advanced manufacturing systems. We’ll start with the different types of representation of CAD models, how you communicate a shape to the CAD system, and how you digitally simulate a shape and object you want to manufacture without needing to actually produce it. We’ll also talk about how you can use the computer to generate or optimize an object for a task, physical or geometric constraints, how to work in partnership with computer as efficiently and well as possible. Speakers from area companies that make the technologies will address the class as well.

Upon completing the course, “participants will walk-away with a better understanding of how CAD systems are built and how to use them effectively and knowledge of some of the latest digital manufacturing processes including additive manufacturing and 3D printing.”

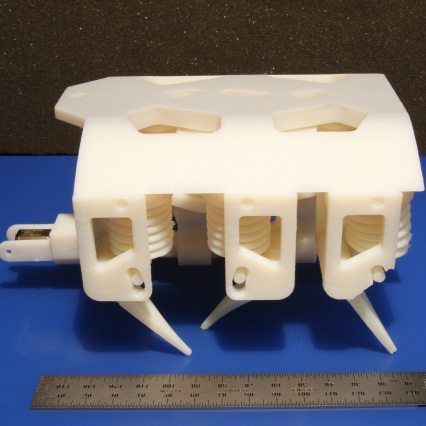

Attendees can expect a mixed group of fellow students, “We are hoping our class will include research scientists, engineers, developers, designers, and project managers in industries that interact with CAD software to make physical objects.” The course is designed to appeal to those in the the automotive industry, robotics, aerospace, defense, mechanical engineering, product design, shipbuilding, biomedical engineering, and prosthetics manufacturing.

The future of manufacturing

I asked the instructors about the manufacturing trends they see for the near to medium term,

In the future, design and manufacturing will be collocated, putting designers close to the machinery and staff needed to make their visions into physical reality. This transition from outsourcing to internal manufacturing is facilitated by digitalization and automation, making manufacturing on-demand. The end result is a blurred line between product prototyping and manufacturing.

These changes mean that, “Professionals in the space will also face challenges, such as improving the iteration cycles for product design/manufacturing.” The MIT professors point out that, “Digital manufacturing (e.g., 3D printing) is becoming commonplace, and professionals will need to learn how to incorporate these new capabilities into their creative process.

Furthermore, “collaborative design will require organizations and professionals to re-think the manufacturing workflow.”

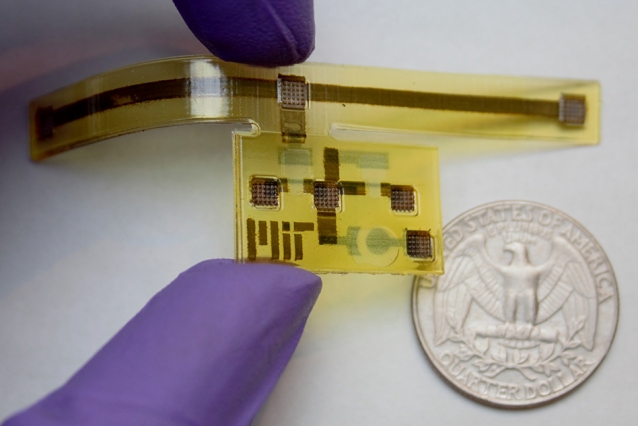

You can read more about course instructor Wojciech Matusik’s work on 3D printed autonomous sensory composites and how the project had an unusual influence here.

3D Printing Industry also took a look at how MIT are creating the Photoshop of 3D Printing in our article about Foundry, another project from MIT’s Computer Science and Artificial Intelligence Lab (CSAIL).

The MIT Advances in Computer-Aided Design for Manufacturing course runs from June 26th to June 30th and costs $4,750.

Don’t forget to place your votes in the 3D Printing Industry Awards, and if you’d like to attend the event tickets are available here.

For the latest 3D printing news, sign up to our newsletter and follow us on twitter.

Featured image shows MIT professor Justin Solomon. Photo via MIT.