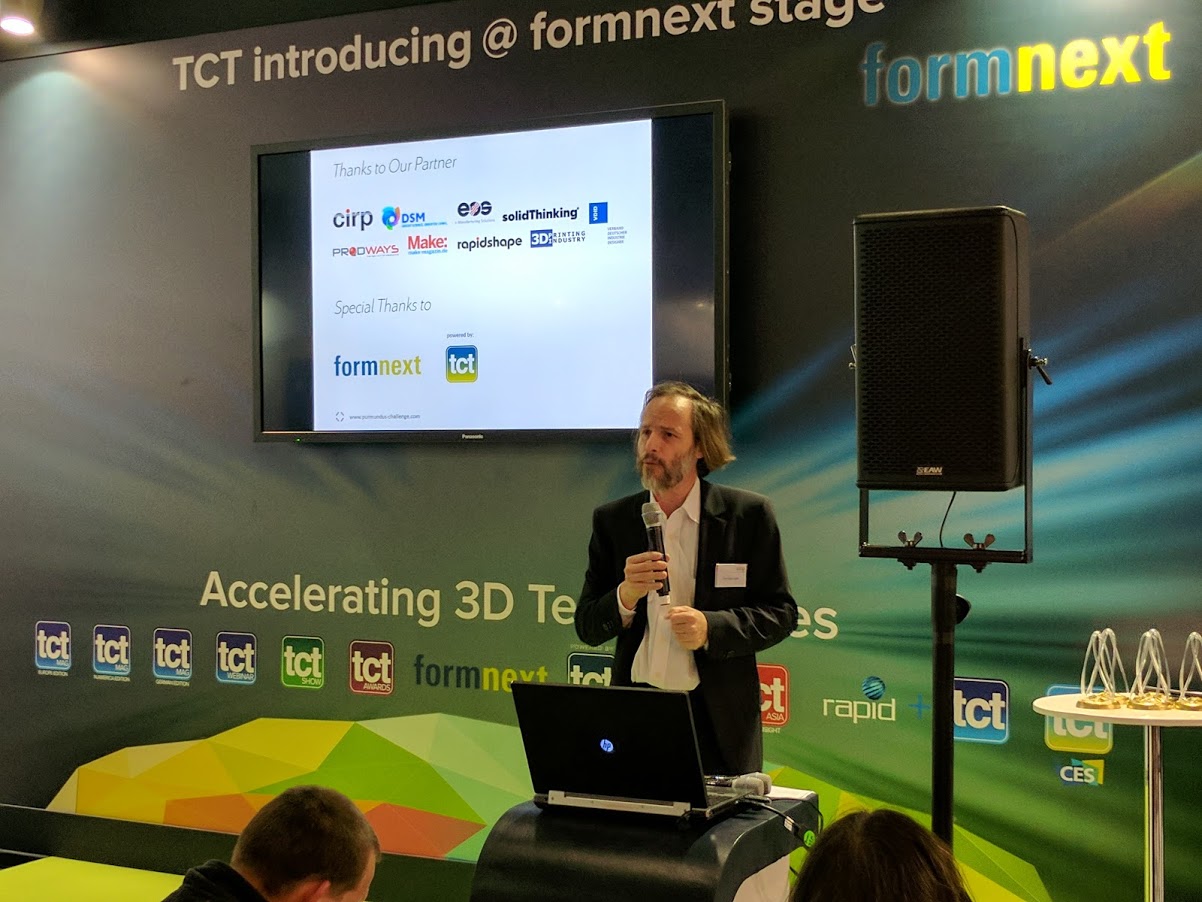

At Formnext this year, FirStep was announced as the winner of the Purmundus Challenge. There were five total winners of the gold trophies presented at the fourth annual challenge in Frankfurt on 17th November. The aim of the competition is to promote innovative use of 3D printing by creating designs that could only be made using additive manufacturing.

The main theme this year was mobility, designing for a person on-the-go and the winning entry was a foot prosthetic for children. During the conference in Frankfurt, eighteen finalists presented their submissions which included an electric motorbike (far right, above), an electric scooter, and a hyperboard.

To produce their winning design, the firStep, Mecuris used CAD and 3D printing in order to recreate a child’s foot in prosthetic form. Creating child prosthetics traditionally can be quite difficult due to there not being as much of a demand as adult prosthetics. With prosthetics for children under the age of five not even in existence. However, Mecuris wished to change that with use of 3D printing, modelling and design. Their efforts being very similar to that of Open Bionics who are creating 3D printed arms for children.

Using a model of the patient’s foot, the team are able to create a model for a prosthetic that will suit the child’s leg. The model will then be printed using the Selective Laser Sintering 3D printing technique in order to produce a custom made prosthetic for a child of any age. This process is both fast and cost-effective. Furthermore the design features a carbon or fiberglass suspension which works similarly to expensive adult prosthetics. At the moment, two children have been mobilized using this innovative technology from Mecuris, and they have received positive feedback thus far. Moreover, these prosthetics have been manufactured and delivered within just one week which is something Mecuris are keen to keep as a standard.

Other winners in the Purmundus challenge include: a 3D printed mesh-like bicycle, a 3D printed bandage device, a sound insulation material, and a customizable 3D printed bicycle. Competitions like the Purmundus Challenge definitely encourage innovative design, as we’ve seen recently with Gramazio Kohler Research group being awarded The Swiss Technology Award 2016 for their construction meshes.

Featured image shows the winners Mecuris. Photo by Michael Petch.