Materialise has listed its 3D-printed cardiovascular HeartPrint models as a Class 1 medical device in the USA and EU markets, extending and strengthening its position in the industry. Though the company has been printing anatomical models for educational and research purposes, Materialise was one of the first companies that addressed the need for advanced medical models. Most of us are familiar with examples of scanning technology being used to help diagnose, plan and practice complex cardiovascular procedures, especially in infants. The Mimics Innovation Suite of software for medical image processing already has a 510(k) clearance from the FDA and a CE mark clearing it for sale in the EEA (European Economic Area).

Besides OPM’s facial device, Osteofab, which is the first and only FDA cleared 3D printed polymeric implant for facial indications, there is little in the way of anything under the 3D printing umbrella (scanning, software, printing) that is properly regulated and approved by any government agencies.

Medical 3D printing is validating the upward trajectory of the entire 3D printing industry. Prosthetics, orthotics, tooth implants, skin, kidneys are the most relevant justification for all of the hype and market projections. But separating the acts of scanning, imaging and software manipulation may soon need a new title. It isn’t really just the 3D printed model alone that is the hero. The software and scanning technology are all becoming part of the same process, and that is going to become as crucial for future market analysis and industry projections as it is for these complicated cardiovascular diagnostics and procedures. Just ask Bradley White, a 16-year-old boy who was born with a tumor that resulted in an erratic heartbeat. With the aid of Materialise’s HeartPrint® 3D-printed model, his doctors were able to determine the best treatment for Bradley’s condition.

According to Dr. David Morales, the Chief of Cardiovascular Surgery for the Heart Institute at Cincinnati Children’s Hospital Medical Center, “Where I think clinically 3D printing will take us, is to the next generation of imaging. As we’ve seen in the history of medicine, the better and better our imaging, the more precise we are to pre-operatively be able to say what operation we’re going to do.”

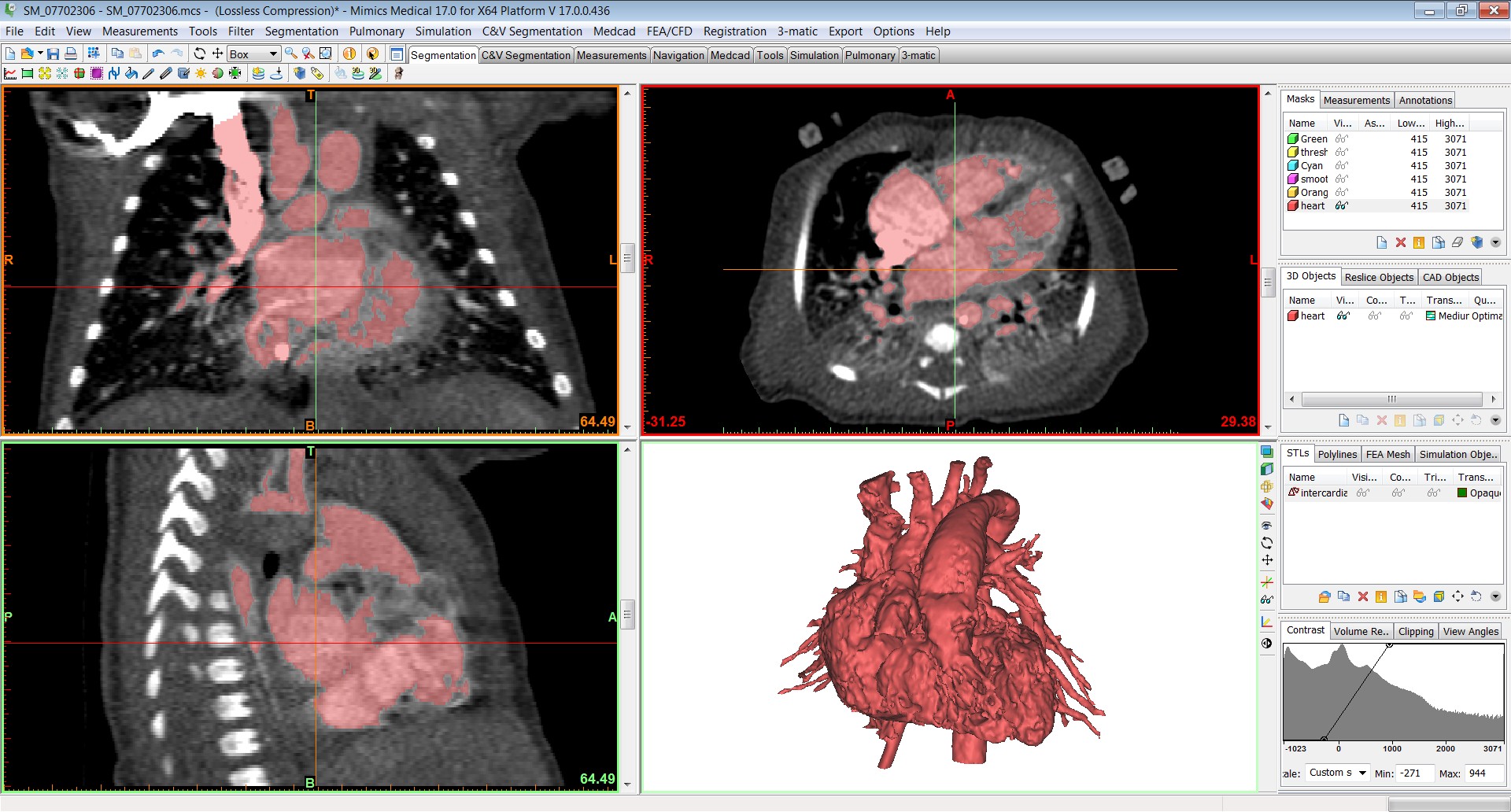

There was a story recently about a 1-week-old baby who was born with a complex form of congenital heart disease in which both the aorta and pulmonary arteries arise from the right ventricle as well as a large hole in the heart called a ventricular septal defect (VSD). A day after his birth, an extremely low dose chest CT scan was acquired and data was sent to Todd Pietila the Cardiovascular Business Development Manager at Materialise. He created a digital 3D model of the baby’s heart using Mimics® and then 3D-printed a replica complete with miniscule details. The team of clinicians at the New York-Presbyterian/Morgan Stanley Children’s Hospital used the model to find a solution for repairing all of the baby’s defects in one procedure rather than the typical series of palliative operations which can be life threatening.

“After the success of this surgery, it’s hard to imagine entering an operating room for another complex case without the aid of a 3D printed model. It’s definitely going to be standard of care in the future and we’re happy to be leading the way,” said Dr. Emile Bacha, a congenital heart surgeon and Director of Congenital and Pediatric Cardiac Surgery at New York-Presbyterian/ Morgan Stanley Children’s Hospital.

Regulatory agencies have raised concerns about 3D printing in a clinical environment because there is no quality assurance system in place to ensure accuracy and safety. The Mimics Innovation Suite (for segmenting the medical image data) and Streamics (for segmenting the medical image data is dedicated to automating) are completely alone in the industry because they are addressing quality assurance concerns by controlling and tracking the 3D printing process. They ensure both traceability and clinical-level quality standards.

“We’re proud that the Mimics Innovation Suite is one of the few engineering packages with the appropriate validation to be considered a medical device. This makes it easier for Materialise and our customers to bring patient-specific, 3D-printed treatments to the market. It’s important for us to stay ahead of the regulatory requirements,” Koen Engelborghs, Director of Biomedical Engineering at Materialise, states. “We saw the advantages for patients when HeartPrint models were used in a clinical environment and are looking forward to continuing our collaborations with hospitals to address their 3D printing needs.”

Materialise is accomplishing and providing a clear, fully regulated and clinically approved example of how 3D modeling software and scanning technology can help doctors save lives and increase the level of care that each patient receives. This is great for society, and the 3D printing industry.