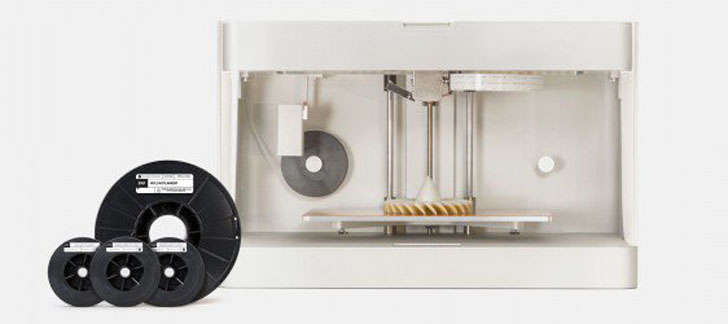

Upon the release of their Mark Two composite 3D printer, Markforged has announced a new material with which to print composite parts. The new material, a type of fiberglass, is even stronger and more heat-resistant than the firm’s previous fiberglass material, making it ideal for use in the automotive and aerospace industries.

The Mark Two works by feeding a continuous strand of composite material into a nylon part as it’s being 3D printed, allowing for greater strength than filaments made up of chopped reinforcement materials. Now, Markforged’s portfolio of carbon fiber, fiberglass, and Kevlar® materials has been expanded to include high-strength high-temperature (HSHT) Fiberglass. The material is twice as strong and has a 30% higher heat deflection point (140°C) than the former fiberglass material. CEO Greg Mark says of the offering, “2016 is the year of materials at Markforged. Throughout the year you’ll see the release of stronger, more advanced materials that expand the range of parts that can be 3D printed.”

As Markforged has already begun shipping the new Mark Two 3D printers, the company will now be including the HSHT Fiberglass material with the Mark Two Enterprise Kit, currently available for purchase.