Award winning 3D printer developer Markforged has officially shipped the first batch of its Metal X systems to customers around the globe.

3D Printing Industry has seen several of these printers demonstrated by re-sellers in Europe and the U.S during the past months.

Though the company has not yet disclosed order or unit numbers at this time Trak Lord, Markforged Director of Communications, confirms that “the interest has been considerable and this is the first shipment of many.”

Industrial tooling and household hardware manufacturer Stanley Black & Decker has also become the first company to install a full Metal X system – the 3D printer, a Sinter-1 module and the Wash-1 for post-processing.

Greg Mark, founder and CEO of Markforged, comments, “Markforged systems, such as the Metal X, are changing the way businesses produce strong parts while dramatically impacting the delivery times, cost, and supply chain logistics,”

“We’re thrilled that STANLEY Infrastructure recognizes the value in the acceleration and cost savings that 3D printing low volume metal can add to traditional manufacturing processes.”

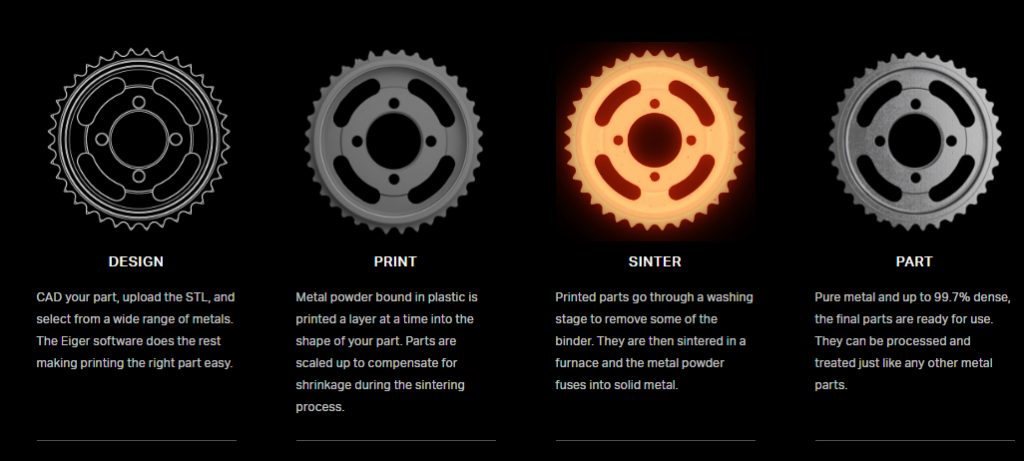

Atomic Diffusion Additive Manufacturing

The Metal X 3D printer made its premiere at CES 2017. The value proposition for the Metal X is low-cost metal 3D printing within a desktop setting. At the time of release, Mark commented, “If you can afford a half million to million dollar metal printer, buy one. For the rest of the World, this is for you.”

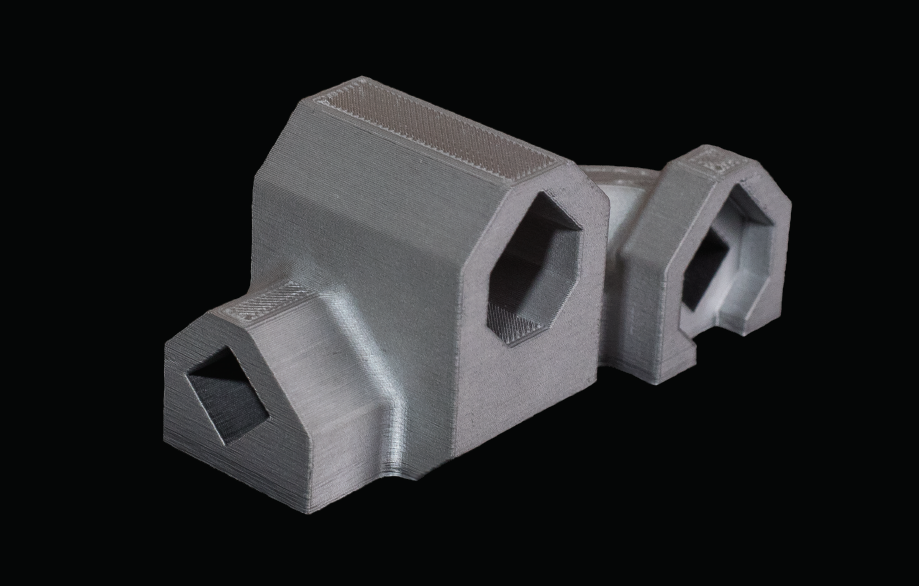

The Metal X uses Markforged’s proprietary Atomic Diffusion Additive Manufacturing (ADAM) technology. In the process, a metal powder is combined with a binder and extruded onto the print bed, just like typical FFF/FDM 3D printing. When complete, the part is sintered in a kiln and washed to rid it of any unwanted residues. The sintering process gives the 3D printed parts exceptional mechanical properties in all directions.

STANLEY collaboration

Markforged is working with Stanley Black & Decker to develop effective applications for the Metal X 3D printer in the company’s product development division.

With a full Metal X system, STANLEY has discovered a more cost-effective method of manufacturing complex, low volume parts. In a preliminary trial run, two Markforged 3D printed parts have already made it through the full product lifecycle at STANLEY, undergoing rigorous performance and durability tests.

By rolling out this process across more small parts, STANLEY expects to make a cost savings of over 95% with parts that are also as much as 50% lighter than the traditionally made counterparts.

“For our team, the Markforged Metal X printing system requires minimal capital and time investment to make the parts we need,” explains Harry Zhong, Technical Lead at the STANLEY Infrastructure Innovation team.

“With Markforged, we believe that we can save thousands of dollars per year per part while retaining the quality and reliability we expect from traditionally machined parts,

“These kinds of innovations from Markforged are going to fundamentally change the way we think about manufacturing.”

To stay up to date with all the latest 3D printer releases and business follow us on Twitter, like us on Facebook, and subscribe to the 3D Printing Industry newsletter,

Cast your votes in the 2018 3D Printing Industry Awards now.

Find your next opportunity at 3D printing jobs and post a vacancy here.

Featured image shows the Markforged Metal X 3D printer. Photo via Markforged