Stanley Black & Decker, a manufacturer of hand tools, machining tools, and outdoor machines has redesigned and 3D printed two complex components using the Markforged Metal X 3D printer.

The components, an actuator housing for a PD45 Hydraulic Post Driver and a wheel shaft for the PG10 Profile “Frog” Grinder, were tested and cleared for use as production parts. Analysis showed that the 3D printed parts cost a fraction of the original components.

This is the latest 3D printing announcement from the Connecticut-based hardware manufacturer since it launched a mentorship program in collaboration with startup accelerator Techstars.

3D printing the actuator housing for a post driver

A post driver is a machine that forces posts and poles into the ground using a hydraulic driving mechanism. The part in question houses a group of ball bearings to transfer the pull force from a manually operated trigger into the hydraulic actuator that starts the post driving mechanism.

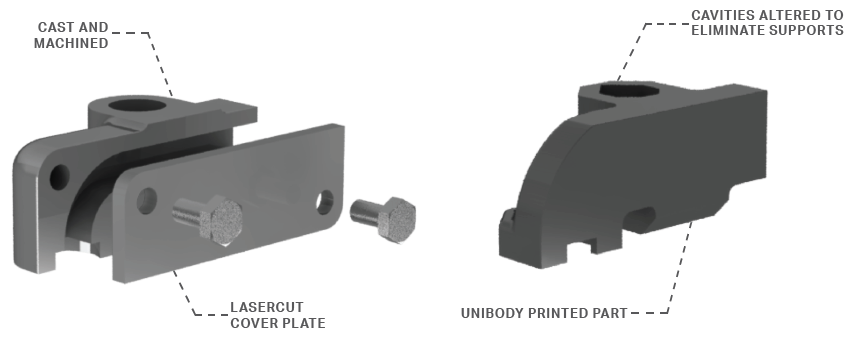

The original actuator housing was made up of 4 parts: a cast and machined main housing (containing the ball bearings), a laser cut cover plate, and two bolts to hold the assembly together.

This housing, like components of other high-pressure systems manufactured by the likes of Aidro, must be strong enough to withstand the vibrations of the hydraulic driving mechanism.

The part was redesigned by engineers at Stanley Black & Decker in only one piece. To eliminate the need for supports, the circular cavities were redesigned as polygonal ones.

Testing the 3D printed post driver

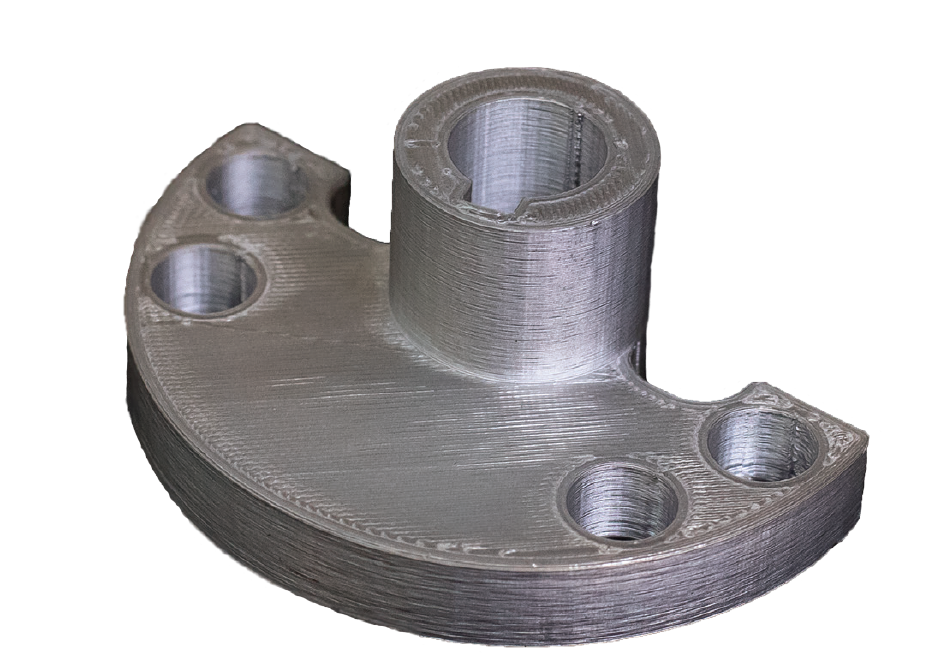

The part was then tested through tens of thousands of cycles. Analysis showed that the part was not only durable and strong enough to withstand the load, but it was also 53% lighter.

3D printing a single part using the Metal X was 20x faster than machining the part, reducing lead times by 95%. This indicates that overall lead times for the average annual output would be cut by 69%.

A Stanley Black & Decker engineer working on the study commented that,

“It is very feasible to leverage the Metal X platform in additively manufacturing the discussed actuator housing with very minimal capital and time investment.”

3D printing the part was also 12.5x cheaper than machining. Cost savings for a single component were reduced by 92%, which translates to a cost saving of between 34% and 48% relative to the annual volume of the components.

3D printing a wheel shaft for a profile grinder

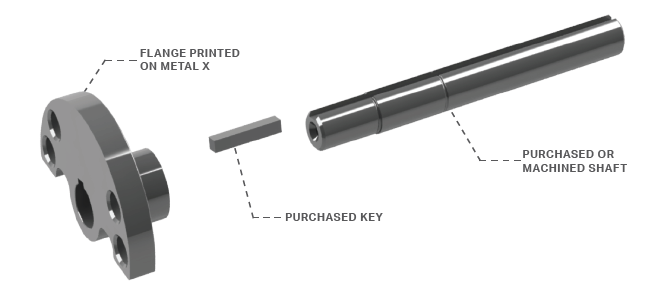

A profile grinder is a piece of equipment that performs surface finishing on railway tracks before they are put in place. The wheel shaft holds adjustable guide wheels on to the grinder and must withstand the machine’s full weight. The part consists of a semi-circular flange (a projecting edge) with a central shaft running through it.

Previously, Stanley Black & Decker machined the flange and shaft (as one piece) out of a block of steel, wasting up to 90% of the stock material in the process.

Using the Markforged Metal X, Stanley Black & Decker engineers 3D printed a flange and then attached a machined a shaft and a key.

Testing the wheel shaft

Testing involved dropping the entire part (consisting of all 3 components) from low and high heights on to a steel surface.

The part proved durable and was 20% lighter than the original. Lead times were halved and the part was produced 25 times cheaper.

In terms of one-off production, this reduced costs by 96% and lead times by 98%. For annual volume, this translated to cost savings of between 25% and 40%, and a cut in lead times of 48%.

Unlike the actuator housing that was reduced to a single part, this component was divided into three parts, but significant time and cost savings were nonetheless achieved.

Tell us who you think the best 3D Printing OEM was this year. Make your nominations for the 3D Printing Industry Awards 2018 now.

For more stories on 3D printing case studies, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows the redesigned and 3D printed actuator housing. Photo via Stanley Black & Decker.