The Netherlands based company CEAD is developing a large-format Continuous Fiber Additive Manufacturing (CFAM) machine for industrial applications, including construction and shipbuilding.

Continuous fiber 3D printing

CEAD has not revealed the specifications of their CFAM process, as they are still in the process of securing patents, however other solutions for working with carbon fiber are already on the market. It will be interesting to learn how the CEAD process compares.

Continuous fiber 3D printing has been commercially available since 2015, with the release of the MarkForged Mark One. Continuous Fiber Fabrication (CFF) is a process developed and coined by Markforged, a Massachusetts-based producer of 3D printers.

CFF uses two print nozzles to produce parts with continuous strands of composite materials, such as carbon fiber, fiberglass or kevlar. The first nozzle follows a conventional printing process, extruding the outer shell of a part in layers. The second nozzle deposits a continuous strand of material on every layer that MarkForged CEO, Greg Mark, says produces components “five times stronger and twenty times stiffer” than regular 3D printed parts. Currently, MarkForged do not offer 3D printers with build sizes as large as CEAD’s CFAM machine. Read more about CFF in a 3D Printing Industry interview with Mark.

Testing and production

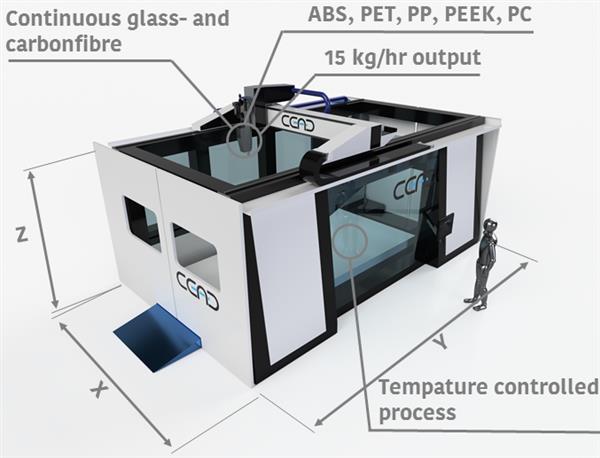

In January CEAD revealed some key specifications of the 3D printer, including an impressive max build size of 4x2x1.5m and a deposition rate of 15kg of material an hour. The printer is compatible with many different thermoplastics, including ABS, PET, PP and PEEK.

Since then, CEAD has successfully tested the impregnation and extrusion of continuous glass and carbon fiber materials in the printing process. During the test the CFAM machine ran for 24 hours without operator interference. CFAM samples were subjected to several interlaminar shear strength (ILSS) tests showing parts conforming to several ISO standards.

CEAD have moved production to a larger 1000 square meter facility, located near Delft, Netherlands. The location will be used to produce the first full-scale CFAM machine.

The company say the CFAM 3D printer will be available this year.

Be the first to read about the latest 3D printers and 3D printing technologies. Subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Vote in the 2018 3D Printing Industry Awards, before it closes.

Post a job, or kick-start a career in 3D printing. The 3D Printing Industry Jobs board is live.

Featured image shows CEAD’s logo. Photo via CEAD.