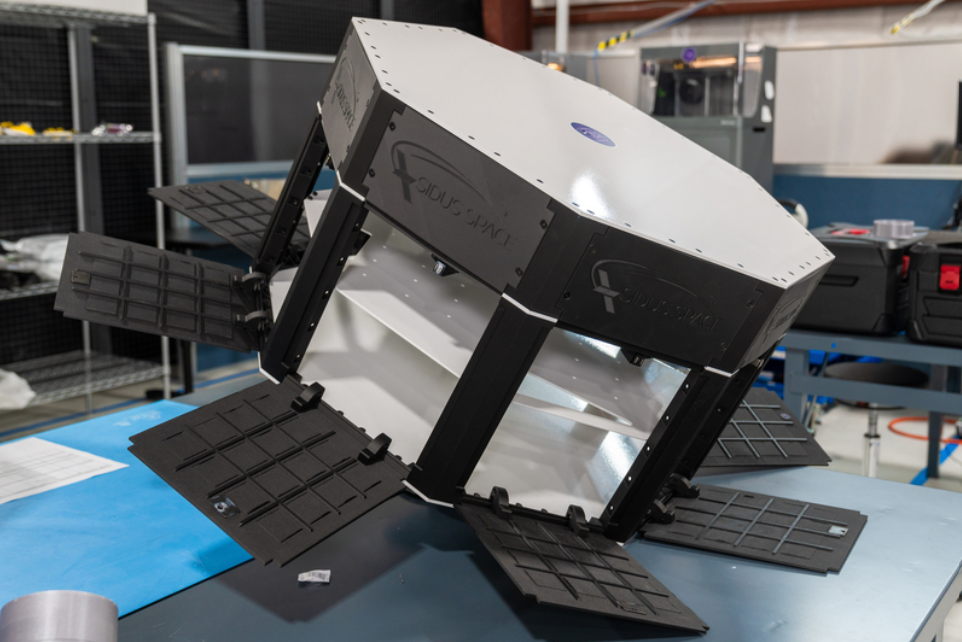

3D printer manufacturer Markforged has unveiled a YouTube video that showcases the “work in progress” 3D printed LizzieSat satellite. This satellite is being developed in partnership with aerospace company Sidus Space.

According to Sidus Space, the satellite must comply with the stringent certification standards of aerospace engineering, while also being limited to a maximum weight of 100 kg. To tackle this complex engineering feat, Tony Boschi, a former NASA engineer, and Lead Design Checker has been leading the project. Boschi said, “You’ve got batteries, computers, all the components that make the satellite operate that take up significant weight – the more weight I can remove from the rest of the structure, the more payload we can put in.”

Sidus Space utilized Markforged’s flame-retardant Onyx FRA material to produce components with metal-like strength, while also reducing weight and production time. According to Sidus Space, the 3D printed prototypes on its flight test platform, made using Onyx FRA, remained intact and functional even after a year in space outside the International Space Station (ISS).

Furthermore, these partially 3D printed LizzieSat satellites are capable of hosting customer sensors and other technologies. It is also capable of collecting valuable data on various industries, such as aviation, maritime, weather, space services, earth intelligence and observation, financial technology, and the Internet of Things. Additionally, Sidus Space’s first 3D printed satellite is expected to launch this year on the SpaceX Transporter-9.

LizzieSat Constellation transforms geospatial intelligence with 3D printed components

The LizzieSat multi-purpose constellation is created to cater to the specific needs of both commercial and government demands in today’s data-driven, cloud-based, and interconnected world. The platform intends to capitalize on the shift from static and low-frequency satellite imaging and geospatial solutions to real-time geospatial intelligence, which is now more accessible on demand.

By incorporating 3D printed components, LizzieSat benefits from a faster and more efficient fabrication of satellite parts. These components are manufactured using Markforged 3D printers, known for their high precision and reliability in space applications. Not only does this technique accelerate manufacturing, but it also results in cost savings and enables more flexible and customized designs. The design of the LizzieSat constellation also allows for compatibility with a diverse range of launch vehicles and deployment from numerous launch sites across the globe.

“Markforged 3D printers initially played an important role in our successful External Flight Test Platform (EFTP) mission, an on-orbit external experimental facility that was hosted on the NanoRacks International Space Station External Platform (NREP),” said Carol Craig, Sidus Space Founder, and CEO. “Building on the success of our EFTP program, we have continued to leverage Markforged solutions in the development of LizzieSat.”

Sidus Space leverages Markforged 3D printing for reliable and cost-effective solutions

“Markforged has been an incredible partner to us over the years,” added Craig. “We are honored to be highlighted in one of their videos, as it speaks to our commitment to providing innovative, reliable, and cost-effective solutions to our customers.”

Sidus Space has utilized Markforged 3D printers to produce components for various programs quickly and effectively, allowing the company to meet customer demands in a timely and cost-effective manner.

According to the company, when the impeller on the machine that produces Sidus’ custom screws broke, it would take weeks to months to get a replacement part. However, with the help of Markforged, Boschi was able to 3D print an exact replica on a Markforged X7 in less than 40 minutes. The printed design has been in service for over a year, unlike the original OEM part which had to be re-ordered every 3-6 months.

3D printing changing the game for satellite manufacturing

Sciperio, an engineering firm affiliated with Florida-based microdispensing specialist nScrypt utilized the nScrypt Factory in a Tool (FiT) to 3D print CubeSats for the US Space Force. This was part of the Small Business Innovation Research Program (SBIR) Phase II project, which aimed to manufacture and assemble 6U CubeSats with a high degree of sophistication. Ken Church, CEO of both nScrypt and Sciperio said, “nScrypt’s FiT provides the ability to rapidly fabricate a small satellite to respond to an immediate need. For example, the Space Force will be able to react rapidly to meet new threats by compressing the time from design to orbit.”

3D Systems announced it was contracted by aerospace manufacturer Airbus to 3D print parts for its satellite dubbed OneSat. The OneSat is unique in that it is fully reconfigurable while in orbit, allowing it to alter its coverage area, capacity, and frequency dynamically, as opposed to traditional satellites, which are designed for specific missions. 3D Systems used its DMP Factory 500 platform to produce parts of the satellite’s antenna arrays in a way that could enhance the performance after being selected to help build the device.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows LizzieSat early prototype. Image via Sidus Space.