Australian heat transfer specialist Conflux Technology has partnered with German-based space rocket manufacturer Rocket Factory Augsburg (RFA) to embed their 3D printed Conflux heat exchanger technology into an orbital rocket.

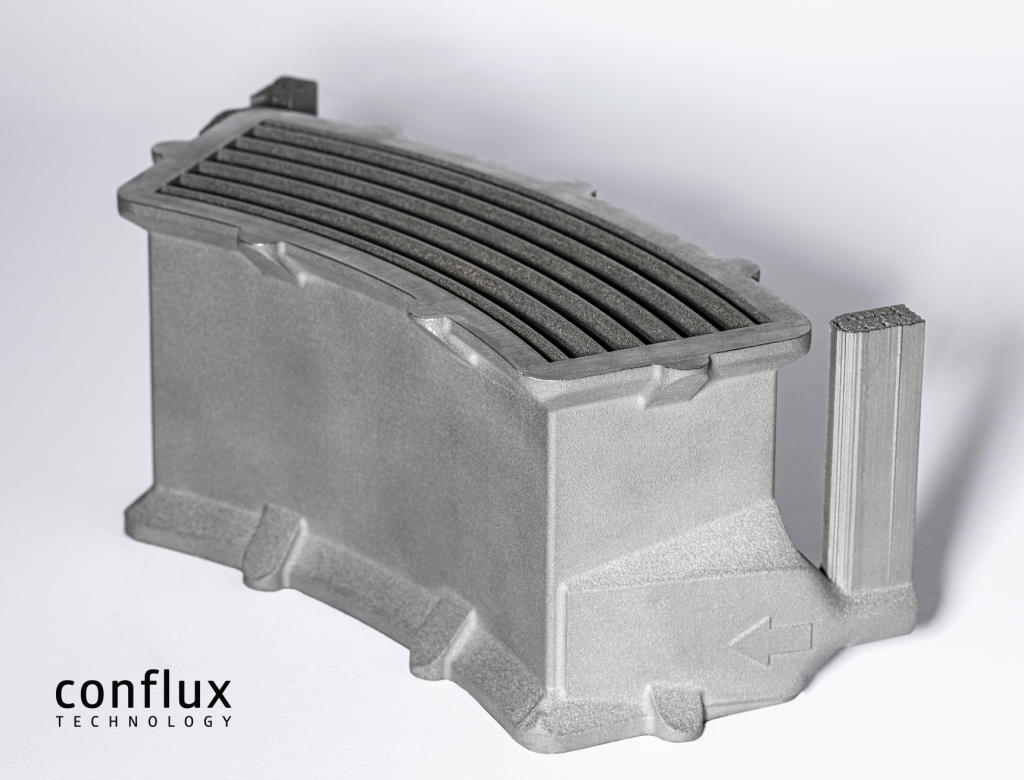

The heat exchanger components are produced using Conflux Technology’s Monel K 500 metal alloy material, and printed using EOS M300-4 Direct Metal Laser Sintering (DMLS) technology. The gas duct heat exchanger is set to be developed, manufactured and put through a functional test later this year.

Part of the Australian Space Agency’s Moon to Mars Initiative, this project is funded by the Supply Chain Capability Improvement Grant Program which awarded Conflux $1 million AUD last year. This initiative and grant aids Australian run projects that could contribute to NASA’s ongoing mission to conduct human spaceflight to the Moon, and eventually Mars. Equally, the initiative also supports the Australian Space Agency’s long-term goal to grow the aerospace industry in the country.

“At conflux we are establishing ourselves as leaders in the development and commercialization of 3D printed thermal solutions and relevant materials for extreme applications,” commented Conflux Chief Commercial Officer Dan Woodford. “With support from the Australian Space Agency’s Moon to Mars Grant Supply Chain Capability Improvement grant, we are now applying it to the rapidly expanding space industry.”

When the funding was announced, Conflux CEO and Founder Michael Fuller said that “We are extremely excited to put our HXs into space! This grant will facilitate the technical development and commercial deployment of our heat exchangers in the most extreme environments…rocket engines.”

Conflux Monel K 500 and EOS M 300 technology

Conflux’s Monel K material, a nickel-copper alloy, is known for its high corrosion resistance, strength and durability, and sees extensive use in marine and chemical processing applications. Monel K is also notable for its resistance to stress corrosion cracking and pitting corrosion, a form of localized corrosion that causes the random creation of small holes in metal.

However, the K 500 variant has been further strengthened through age-hardening and precipitation hardening, offering improved strength and hardness. Thus, Monel K 500 possesses a high yield strength, tensile strength and improved corrosion and erosion resistance, making it ideal for high-stress aerospace applications and the production of heat exchanger parts.

To manufacture the heat exchanger components with Monel K 500, Conflux is leveraging their EOS M300 Direct Metal Laser Sintering (DMLS) machines, which they purchased last year. Offering a 50% increase in build volume over its predecessor, the M300 also offers strong reliability through improved layout, functionality, hardware and software.

Additionally, the M300 incorporates 4x lasers which can operate simultaneously on any area of the powder bed, with each laser not being limited to a single working quadrant. This feature reduces build times, ultimately enabling a higher throughput for production. Moreover, the EOS technology also offers a gas-flow-optimized process chamber with the EOSYSTEM SmartCal calibration tool, ensuring high build quality and repeatability. So much so, Conflux claims that this technology has enabled a “significant step forward in production.”

Additive manufacturing and aerospace applications

The use of 3D printing technology within the aerospace industry, especially regarding the production of space rockets, is nothing new. Last month’s launch of Relativity Space’s world’s first 3D printed rocket, Terran 1, marked a significant step forward for additive manufacturing’s role within the space industry.

The rocket, 85% of which was 3D printed, launched from the Cape Canaveral Space Force Station in Florida, but failed to reach orbit before crashing into the Atlantic Ocean. However, Terran 1 still achieved a number of milestones on its maiden flight, establishing itself as the first 3D printed rocket to successfully launch and pass crucial stages such as Max-Q, main engine cut-off (MECO), and second stage separation. Looking forward, Relativity Space has developed its next rocket, Terran R, which is set to launch next year. The company hopes to increase the 3D printed makeup of its rockets to 95% for future missions.

Elsewhere, it was announced last month that California-based space habitation technologies developer Vast has acquired US aerospace firm Launcher, developer of the 3D printed E-2 liquid rocket engine. Through this deal, Vast hopes to leverage Launcher’s 3D printed rocket technology to progress their goal of creating artificial gravity space stations. The firm is already looking to utilize Launcher’s Orbiter space tug and hosted payload platform this year, with a view to reaching orbit and testing its on-orbit space station components and subsystems.

Subscribe to the 3D Printing Industry newsletter to ensure you keep up with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows a Rocket Factory Augsburg rocket engine. Photo via Conflux Technology.