Markforged, an award-winning 3D printer developer based in Massachusetts, has announced its “Metal Monday” sales event, which promises to fulfill every order of its Metal X system received before December 17 by the end of the year.

As of March this year, the company has already shipped over 100 metal 3D printing systems, including printer, sintering system, and washing station. With a less than subtle nod to another Massachusetts based manufacturer, Greg Mark, CEO and co-founder of Markforged said,

“You look at all the companies in the desktop-sized metal 3D printing and all the surrounding hype, but we’re still the only ones shipping. Metal Monday is a commitment to our customers and to the industry.”

“When we say we’re going to ship by a certain date, we’re not going to come back a month later with a different, much longer timeline. We’re moving Metal X out the door faster than ever – there’s no reason to wait around anymore for a metal 3D printer that will change the way you make things.”

While an agreement between Desktop Metal and Markforged over claims of IP infringement, trade secret misappropriation and industrial espionage may have been reached, it appears the two companies remain highly competitive.

The Metal X 3D printer

Introduced at CES 2017, the Metal X 3D printer debuted as a revolutionary system that enables safe and efficient desktop metal additive manufacturing. At the time of release, Mark commented, “If you can afford a half million to million dollar metal printer, buy one. For the rest of the world, this is for you.”

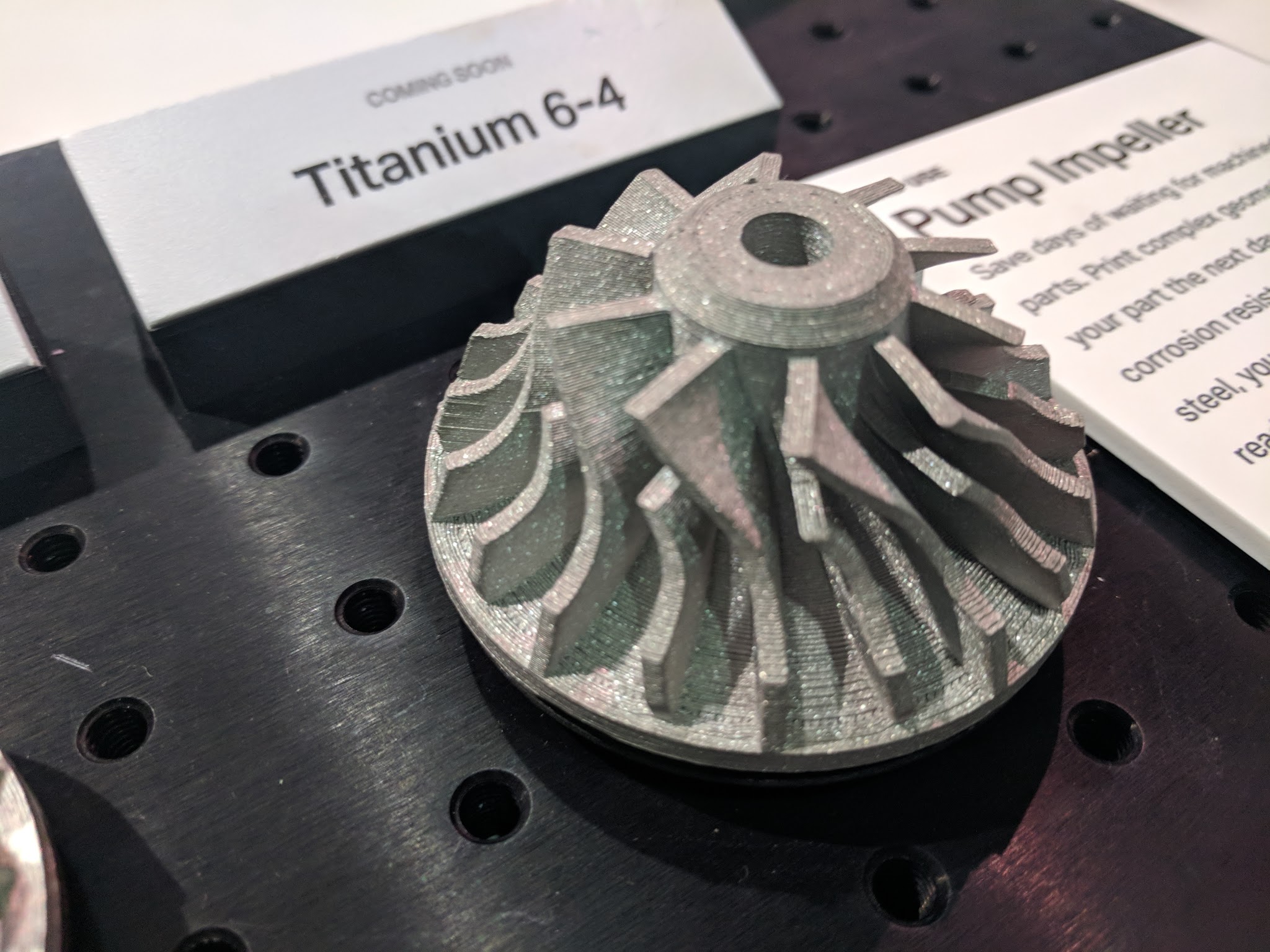

The Metal X can process a wide range of metal materials, some that are not included in established industrial machines. This includes, 17-4 Stainless Steel, 303 Stainless Steel, 6061 Aluminum (Beta), 7075 Aluminum (Beta), A-2 Tool Steel (Beta), D-2 Tool Steel (Beta), IN Alloy (Inconel) 625 (Beta) and Titanium Ti-6Al-4V (Beta).

Markforged officially shipped the first batch of its Metal X systems to customers around the globe in April. Following this, industrial tooling and household hardware manufacturer Stanley Black & Decker became the first company to install a full Metal X system – the 3D printer, a Sinter-1 module and the Wash-1 for post-processing.

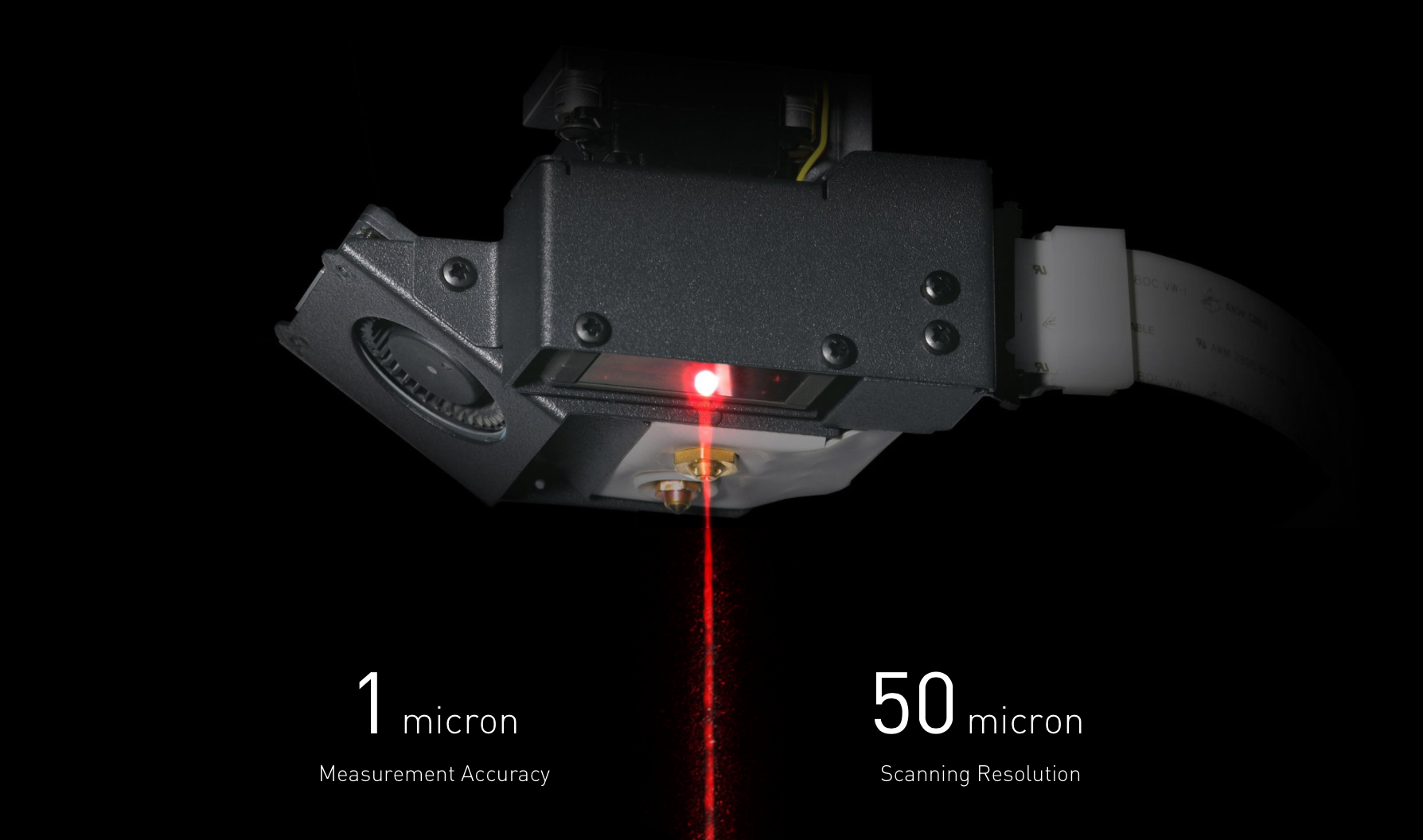

The Metal X uses Markforged’s proprietary Atomic Diffusion Additive Manufacturing (ADAM) technology. This process combines metal powder with a binder which is then extruded onto a print bed, similar to FFF additive manufacturing. When complete, the part is sintered in a kiln and washed to rid of unwanted residues.

The Metal Monday offer extends to all US orders received on or by December 17, and all UK and EU orders received on or by December 11.

Keep up with the latest 3D printing by subscribing to our free newsletter. Also, follow us on Twitter and like us on Facebook.

To commence your career in additive manufacturing or post new opportunities, join 3D Printing Jobs.

Featured image shows the Metal X7 3D printer from Markforged. Photo via Markforged.