UK-based Gyrobot Limited is a mechanical design consulting company with its own 3D printing facility, with which they focus on using FDM to 3D print concept models, end-use parts, functional prototypes, and manufacturing tools. After previously publishing designs for their flexible Flexy Hand 2 and Flexy Finger prosthetics on Thingiverse, Gyrobot has taken to the printables site again with their new “Flexy-Hand 2 Filaflex Remix”, a custom prosthesis for one of their customers.

To create the hand, Gyrobot first scanned the recipient’s limb and printed it with an internal bone-like structure and wrist articulation capability, using variable density “Modifier Meshes” in Slic3r. The hand itself was 3D printed using Skin I Filaflex elastic filament from Recreus. The cool thing about the Filaflex elastic filament is the potential to have layered structures with different shores of hardnesses by combining both PLA or ABS filament with the the elastic material. To do this, one can use any number of 3D printers with a dual extruder.

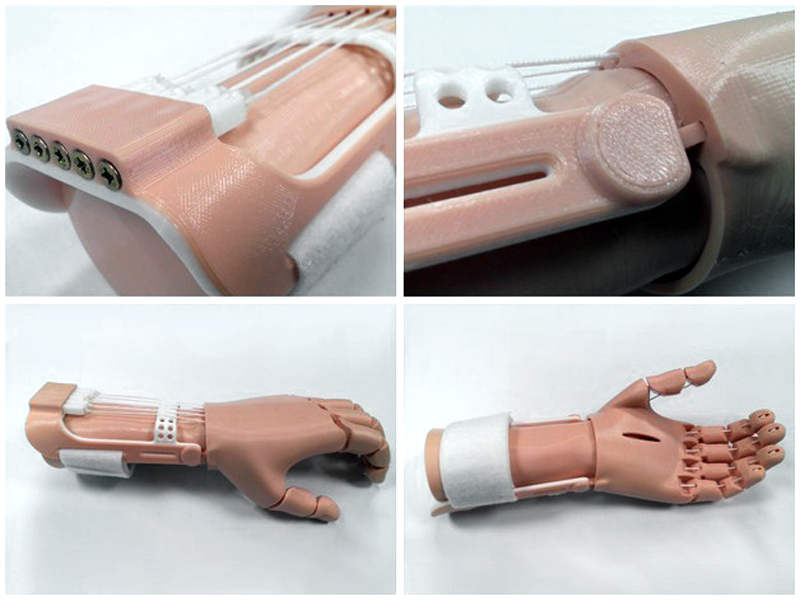

Each finger and thumb were printed in one piece using CraftWare customizable supports. The gauntlet was printed in flat mode with PLA filament, and was then heated in order to bend it 90 degrees. Unlike the fingers, the hand body was printed without supports (except around the thumb) using Skin I FilaFlex filament. Gyrobot tried to print the 5 tensioners in Skin I FilaFlex filament, but found that it allowed the tendon to stretch a bit too much. Instead they printed them using PLA filament, while the two hinges were printed off in FilaFlex filament.

They made a few notable moves when preparing the scanned arm in Meshmixer. By offsetting the outer scanned surface mesh of the arm by 6mm, and waisting in it, they created a noticeably thinner zone in the wrist area. The inner zone was then printed at 45% infill, and the outer zone at 10%, which resulted in a soft flexible feel at first touch. And, when pressed firmly, one is able to feel the impression of bone underneath the surface.

As 2015 unfolds, one of the most exciting uses of all the new materials will be applied to making ever more life-like prosthetics. The detail I was most blown away by here is the fingernails. They came out very realistic looking, at least in the video. I’m especially looking forward to the advancement of silicone printing, from companies such as Fripp Design & Research, which we covered back in 2013.