Scientists from the Korean Atomic Energy Research Institute (KAERI) have 3D printed a large safety valve with sufficient resistance properties to enable its use within a nuclear reactor.

By combining 3D printing and CNC machining, the KAERI team were able to fabricate the 30 kilogram faucet with ultra-precise features, including a set of complex internal cooling channels. During testing, the valve matched the ‘Class 1’ level of safety seen in commercial spare parts, meaning that it’s potentially able to withstand the most severe radiation exposure seen in the nuclear industry.

Maintaining nuclear power plants

As the world continues to move away from fossil fuels, a number of countries have chosen to adopt nuclear energy as a low-carbon alternative. In particular, the USA has become a global leader in nuclear power, generating over 30% of the world’s electricity in this way, and since 2007, it has commissioned a total of 24 reactors.

To ensure that these plants continue to operate safely, and that past catastrophes aren’t repeated, they are frequently maintained and repaired. However, the KAERI team has identified a shortage of certain safety-critical parts such as the Chemical and Volume Control System (CVCS) valve, which is used to relieve core pressure.

Specifically, the CVCS is used to perform fluid supply or flow rate tasks within reactors, and while it can be deployed elsewhere, safety-grade valves always have to meet certain criteria. For instance, nuclear parts must pass water pressure, operation, and flow tests before being deployed, and creating sufficiently resilient components on-demand has previously proven difficult.

Fabricating a heavy duty valve

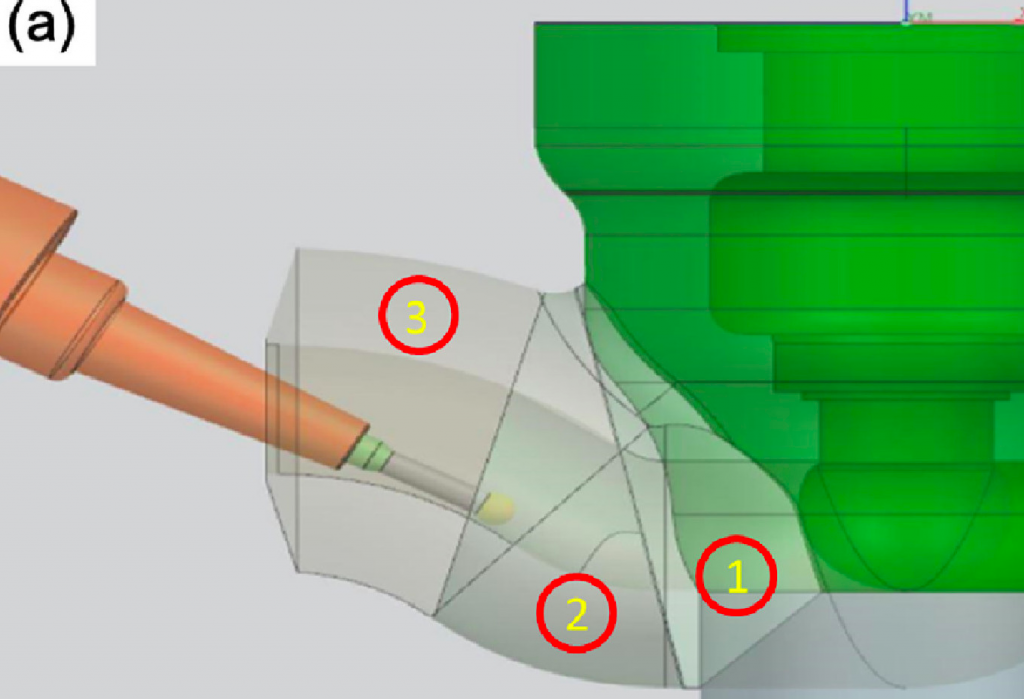

According to the KAERI scientists, metal 3D printing alone, isn’t quite ready to replace conventional production when it comes to creating nuclear spares. However, by marrying a Directed Energy Deposition (DED) technique with 5-axis CNC machining, the team found they were able to fabricate a replica with the extreme level of precision required.

The researchers’ chromium and nickel-based valve featured a 3D printed body, bonnet, and cage, and once assembled, the 300mm device was subjected to a rigorous evaluation. During pressure tests, the device’s layer boundaries were found to act as a focal point for residual stress, reducing its strength by 7-8%.

Similarly, when the CVCS was post-processed in a Hot Isostatic Press (HIP) at 1100oC, it’s integrity weakened by 33%, which was 18% more than that seen in a conventional valve. In terms of consistent performance and its ‘fatigue limit’ though, the additive device bettered the commercial version, with a tensile strength of 202.6 MPa.

Overall, the team concluded that despite its reaction to heat treatment, their additive valve’s constant strength was sufficient to make it ready for end-use. Given that the team’s CECS replicates a Class 1 category component, the IAEA nuclear regulator would classify it as a “part whose failure would lead to consequences of ‘high’ severity.” High praise indeed for the 3D printed part’s strength.

Additive atomic applications

Using 3D printing, it’s now possible to fabricate highly temperature-resistant parts, and over the last year, the U.S. Department of Energy has committed significant resources to developing the technology’s nuclear applications.

Oak Ridge National Laboratory (ORNL) has been central to testing 3D printed nuclear parts, and it installed its first safety-related components in December 2020. By working with the Tennessee Valley Authority (TVA) and fuel supplier Framatome, ORNL was reportedly able to integrate fuel assembly brackets into a reactor core.

ORNL is also in the process of 3D printing a full-on microreactor called the Transformational Challenge Reactor (TCR). Using a combination of additive manufacturing, advanced materials and integrated sensors, ORNL aims to optimize and reduce the costs associated with building nuclear power plants.

Elsewhere, scientists from the Argonne National Laboratory have utilized 3D printing to improve the recyclability of nuclear waste. Using their novel additive manufactured contactor device, the Argonne team believe that it could be possible to reuse up to 97% of wasted nuclear fuel.

The researchers’ findings are detailed in their paper titled “Additive Manufacture of 3 inch Nuclear Safety Class 1 Valve by Laser Directed Energy Deposition.” The research was co-authored by Suk Hoon Kang, Joowon Suh, Sang Yeob Lim, Seungmun Jung, Young Woon Jang and In Soo Jun.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the middle section of the KAERI team’s 3D printed valve. Photo via the Journal of Nuclear Matters.