Jingdezhen is also known as the “Porcelain Capital” because it has been producing pottery for over 1,700 years. Recently, a scientific research team from Jingdezhen Ceramic Institute presented their latest discoveries in the ceramic 3D printing.

Researchers in this team all study majors like ceramic materials, ceramic design and ceramic science and engineering. With an exerted effort, they modified the original 3D printers and achieved a lot of improvement in material formulas. Then they figured out the right ceramic materials that is most suitable for 3D molding.

Compared with the traditional powders, they chose to use shear-thinning fluids that do not depend on resin and contain higher level of solid ceramic. This means that the accomplished model will be more stable and will not be changed in shape very easily. In addition, shear-thinning fluids could be used to print enclosed cavities, which would be impossible for powders.

It is said that their cheapest equipment for ceramic 3D printing is still using deposition modeling and only costs several thousand RMB according to the size. The precision, however, is equal with the equipment that worth 30 thousand RMB in the market.

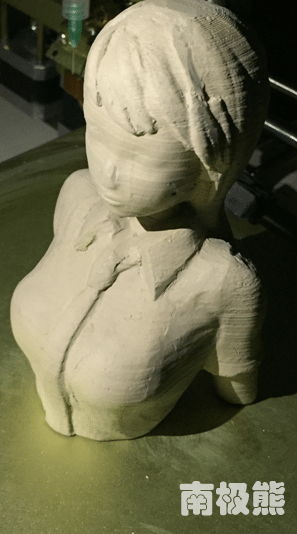

In their early stage, they experimented on the art procelains. We can see from the print lines that they are very delicate. Because of the high solid ceramics in the materials, there won’t be any cracks even when the tempreture reaches 1350℃.

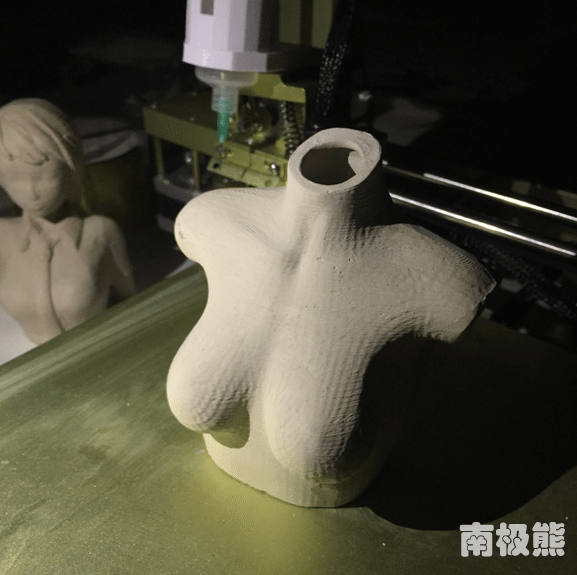

Then the team started to print some complicated objects in other industries.

This is a ceramic implant sample with a nozzle diameter of 0.14mm.

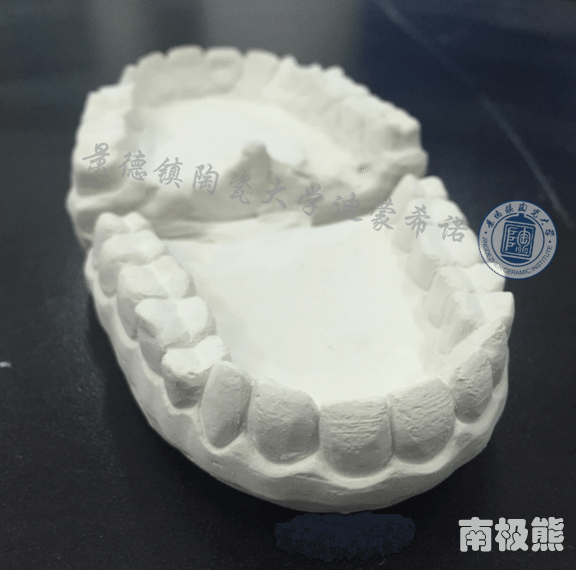

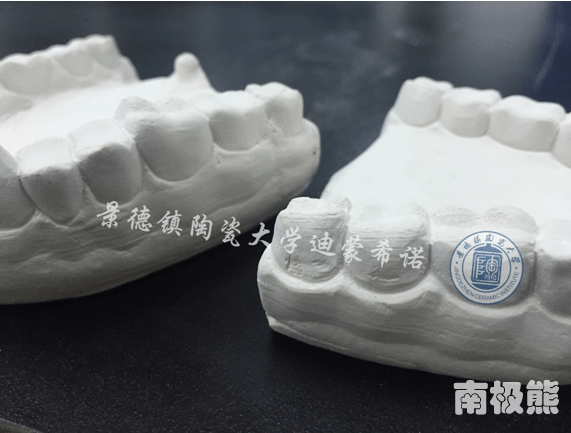

This is the ceramic teeth made of the zirconia ceramic materials.

The advantages of using the zirconia ceramic material is that it is wear-resisting, high-tempreture resisting, corrosion resisting. It is said that a large-scale ceramic 3D printer is coming to the Chinese market soon.

Feature image: nanjixiong