China is an interesting country to report on when it comes to 3D printing because the innovations seem to come fast and furious. WinSun is 3D printing houses in 24 hours, but are they 3D printing them on site? Are they printing walls, adding other components, and using a combination of traditional manufacturing? They are.

I think one of the more deceptive practices in 3D printing journalism is the practice of taking claims like “the world’s first 3D printed x” and not really even mentioning or investigating that numerous other processes were used to create the finished product. It gives people and unrealistic view of what 3D printing is capable of. That’s not to say that, every once in a while, somebody pushes the bar a little higher.

At first glance, the first ever Chinese National Defense Science and Technology Industry Exhibition seems like a typical calling card for a nation’s military agenda. This is the first time that all branches of the Chinese military have presented a unified front, and it’s within the Chinese sector of the military-industrial complex. These types of events are supposed to show off a rapid pace of innovation that will amaze, astound and fascinate other nations and people around the world.

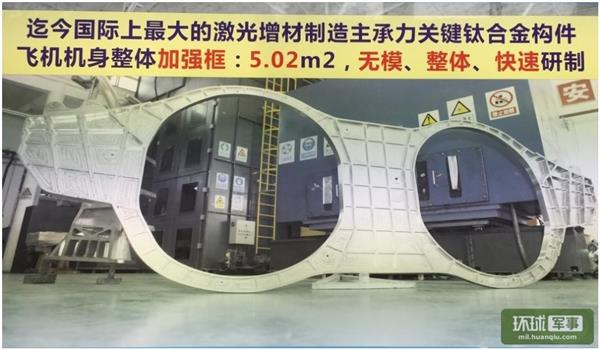

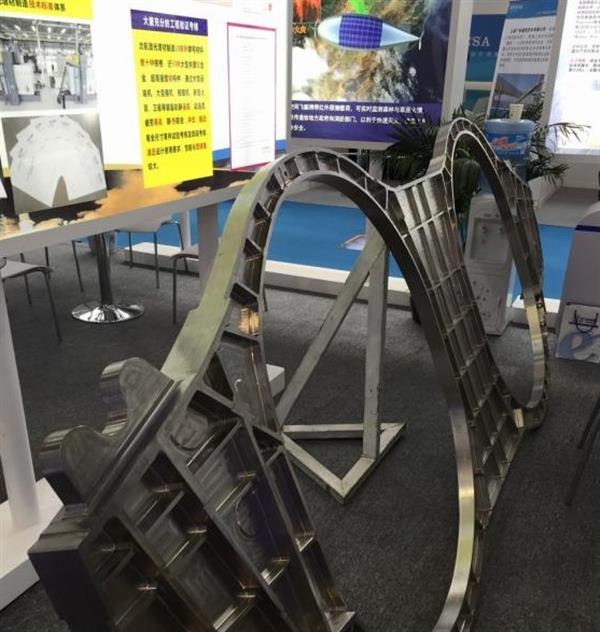

As is typical of many press releases, there is a claim and display: Here is the world’s largest 3D printed titanium alloy load bearing frame for an aircraft ever printed. Yet, it kind of looks like it has had a bath in a CNC machine or other traditional manufacturing process. There is no footage of it being printed or finished, it just comes out perfect, huge, and impossibly fast.

Here’s the official story:

Scientists from Beijing University of Aeronautics and Astronautics have printed over 50 large components for aircraft and aircraft carriers used laser powered 3D printing technology. At the exhibition, staff said that the production cycle was reduced by 80% by 3D printing these components. They also showed exhibition goers a laser sintered C919 aircraft cockpit window frame that they claim can was 3D printed in just 55 days. No word on the cost, but this type of product would supposedly take 2 years and $2 million to make using traditional manufacturing methods.

What I want to know how much this actually cost to build? I think we can be optimistic about the possibilities of 3D printing as it applies to the aerospace industry. GE’s additive manufacturing team printed out a functioning mini-engine, and I see nowhere near that level of innovation coming out of China. Sorry, but I’m a little skeptical of this story.

Look closely and let me know what you think. Am I way off here? Dear Chinese media (which is where everyone broke this story from), tell me how much it cost to 3D print, what other processes were used to manufacture it, and I’ll make a decision on whether or not to be impressed. Boom. Shots fired.