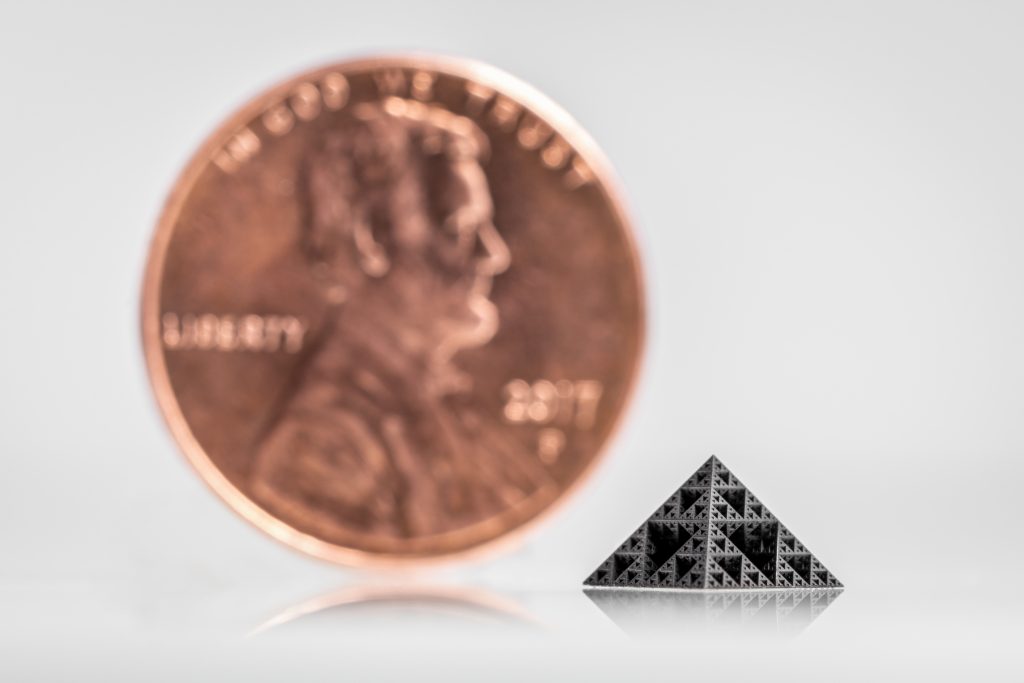

Upon hearing the term additive manufacturing, it’s not uncommon to picture custom tooling components at an automotive facility or highly complex aerospace parts made of Inconel. What many don’t consider is that additive manufacturing at the microscale has a growing number of applications, you just have to look a little closer.

Nanofabrica, an Israel-based 3D printer manufacturer, is a leader in the sector with its own proprietary microscale 3D printing technology. The company’s flagship Tera 250 additive manufacturing system is designed to produce two different types of parts: micro-parts and larger parts with micro-features. The system’s speed and adaptability isn’t something we see all that often in the microprinting world, so the company views it as a big step towards enabling high-volume manufacturing at the micro-scale.

I sat down with Avi Cohen, Nanofabrica’s EVP Global Sales with over two decades of experience in 3D printing, to discuss some of the benefits and applications of Nanofabrica’s microscale 3D printing technology.

Combining precision and speed with the Tera 250

So how does it work? The Tera 250 operates on a micro-DLP light engine. Much like a regular DLP 3D printer, the Tera projects UV light into a vat filled with photopolymer resin, curing it layer by layer into a 3D build. Impressively, the system is capable of achieving a one-micron resolution over a (relatively) sizable build volume measuring 50 x 50 x 100mm. Owing to Nanofabrica’s materials expertise, the 3D printer is compatible with a range of in-house resins based on polymers such as ABS and PP.

Cohen told 3D Printing Industry, “As well as micro-parts, the Tera 250 can build larger macro parts with intricate micro-details, which can be manufactured at speed through what is called a multi-resolution strategy. This means that the areas where fine details are required are printed relatively slowly, but in areas where the details aren’t so crucial, the part is printed at speeds 10 – 100x faster. This makes the 3D printer anything from 5 – 100x faster than other micro-AM platforms.”

The system also features proprietary adaptive optics, which electronically control various critical optical working point parameters such as focus, tilt, and astigmatism. The DLP unit itself is housed on an optomechanical structure that enables real-time corrections of other working parameters, including location and accuracy in the XY plane.

Cohen added, “Crucial to the Tera 250 are the algorithms used to control and optimize the hardware during production. Within the Tera 250, feedback algorithms are used in a closed-loop to increase accuracy and repeatability, while positioning errors are corrected using laser distance measurements.”

Everything from microelectronics to microfluidics

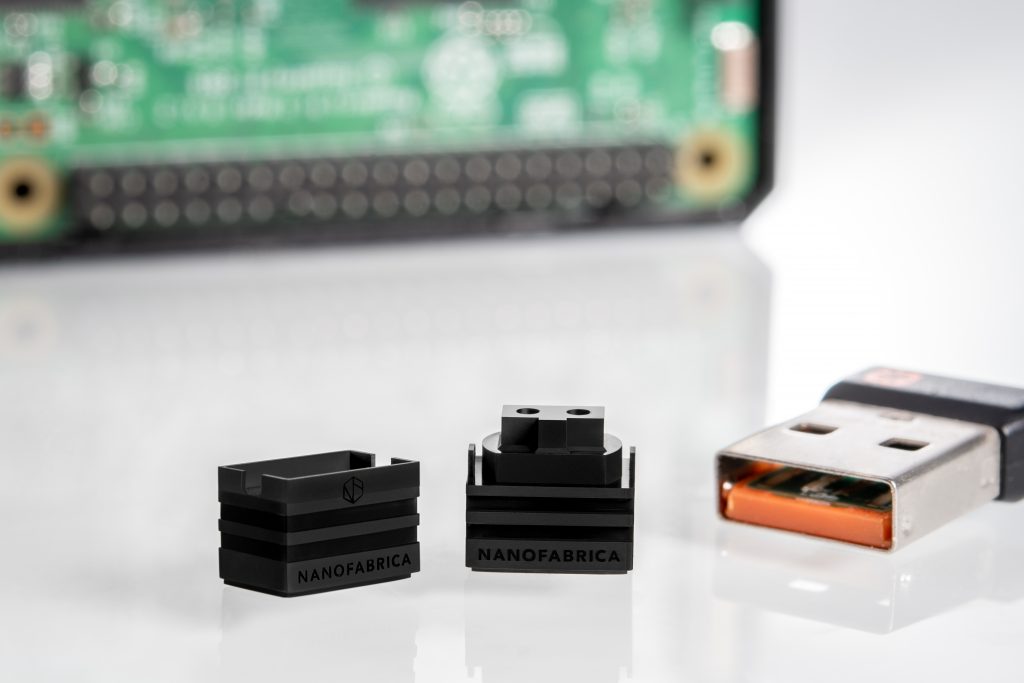

When it comes to applications, Nanofabrica believes there are many. As well as its small part fabrication abilities, the Tera 250 also grants the geometric freedom offered by 3D printing technologies in general. As such, the system is well-suited for custom applications in micro-optics, microelectronics, microfluidics, and life sciences. This includes electronics casings for serially produced wearables, micro springs, and even small-scale, minimally invasive medical implants and surgical devices.

Looking at microfluidic channels, which are used to transport small volumes of liquids, the example is a great demonstration of Tera 250’s ability to outperform traditional manufacturing. Even using a conventional micromanufacturing technique such as micromolding, it would be virtually impossible to fabricate functional substructures into the channels due to limitations in design freedom – a hurdle Nanofabrica jumps with ease.

From a business perspective, the 3D printer also boasts minimal setup costs and absolutely no tooling costs. According to Cohen, “For these applications, the only route to market before the commercialization of the Tera 250 was through the use of disproportionately expensive or restrictive traditional manufacturing technologies.”

Looking to the future, Cohen expects that the drive towards miniaturization and the use of additive manufacturing as a high-volume production technology will not slow down. With Nanofabrica striving to pack more functionality into smaller footprints, applications that rely on high-speed microprinting will be primed for rapid growth.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a microscale part 3D printed by Nanofabrica. Photo via Nanofabrica.