A recent pilot project saw additive manufacturing software developer VoxelDance partner with applications development agency DREIGEIST to streamline production in the footwear industry using 3D printing.

The project involved 3D printing a set of shoe lasts – a special type of footwear tooling that’s used for both manufacturing and repairing shoes. Shoe lasts are usually made of polyethylene or hardwood, but the pilot project made use of the Ultracur3D® RG 35 resin developed by materials specialist BASF Forward AM. Their form, which resembles that of a human foot, has remained largely unchanged for centuries – until now.

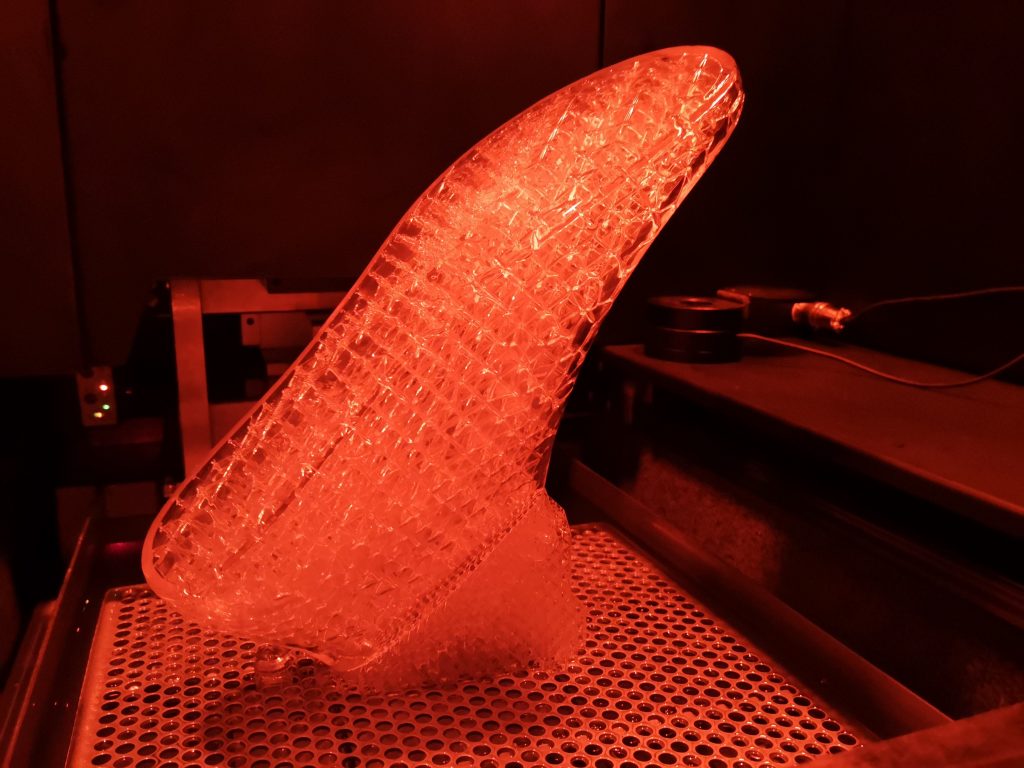

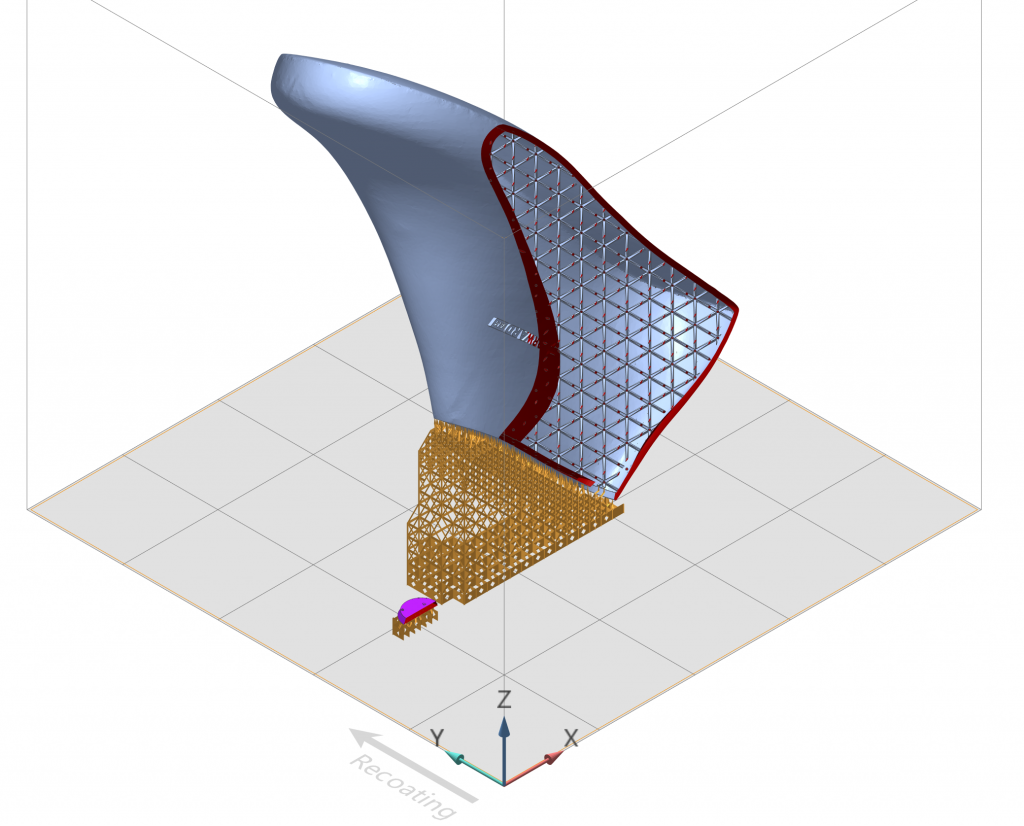

Using the structures module within the VoxelDance Additive Ultimate software suite, the DREIGEIST team managed to drastically reduce material consumption and printing time by replacing the traditional form with a hollowed out one. The novel model, as well as being structurally reinforced, maintained full dimensional accuracy and the performance of the original mold.

The project page writes, “AM delivers a definitive game-changer here: 3D printing the last cuts the lead time to just 6 to 12 hours. Realized with Ultracur3D® RG 35, post-processing, fine-forming and polishing become simplicity itself. Even drilling and tapping to add holding pins or hinges is easy and rapid.”

A crossing of paths

DREIGEIST specializes in using additive manufacturing technologies for serial production applications. Being the first touchpoint for the EMEA activities of VoxelDance, DREIGEIST distributes the company’s software products, acts as the first responder for technical support, and offers a variety of hands-on application training programs for resellers and end-clients alike.

Since DREIGEIST is also actively involved in distribution and technical support for BASF Forward AM, the pilot project naturally popped up on the company’s desk. DREIGEIST used a UnionTech Pilot 250HD SLA 3D printer running BASF’s Ultracur3D® RG 35 photopolymer resin to print the specialty shoe lasts.

Additive manufacturing for footwear tooling

Footwear tooling suppliers often face a whole host of hurdles when manufacturing their lasts using conventional production methods. As well as limitations in geometries, OEMs are forced to develop a whole new model prototype for each style in several sizes, which can be both costly and time-consuming.

With the rapid prototyping and design iteration capabilities of 3D printing, these lead times and operational costs can be kept to a minimum. There is also the issue of IP protection, which can be difficult to ensure when a proprietary design is being transported from point to point in the global supply chains of today. With additive manufacturing, these supply chains can be condensed into a more local region, or even in-house for maximum safeguarding. This also has the added benefit of significantly reducing greenhouse gas emissions from a lack of transportation.

The whitepaper published by Forward AM adds, “Applying AM technology to lasts brings a further decisive competitive advantage: Footwear manufacturers usually have to produce and store lasts in every single shoe size, resulting in a major warehousing headache. Migrating to AM takes storage digital and makes costly warehousing obsolete.”

The benefits of VoxelDance Additive

The 3D printed last builds were prepared exclusively using the VoxelDance Additive data preparation software. Beyond just slicing and support generation functionality, the program allows for on-the-fly part editing and STL model repair, ensuring smooth surfaces and higher print success rates.

Key to this particular build was VoxelDance Additive’s lattice infill structure functionality, which enables users to hollow a part out and replace its internal volume with a lattice. The feature can be used to automatically reduce internal material consumption as well as print times, resulting in further cost and lead time reductions.

Finally, the shoe lasts were sliced using the software’s adaptive slicing abilities. The approach works to restore the shape of the sliced model with Z-axis compensation in mind, meaning it enhances the print speed of the build while maintaining part precision. For readers interested in finding out how this is all done, DREIGEIST has posted a real-time workflow video tutorial here.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D printed shoe last variants – hollow vs solid. Photo via BASF Forward AM.