Over the last two decades, Ellen Lee has worked her way up the career ladder at Ford, a firm synonymous with automotive innovation, which remains one of the world’s leading car manufacturers.

During that time, Lee has witnessed Ford going from an early prototyping adopter to a business that uses 3D printing to create more functional mock-ups, jigs, fixtures and even end-use parts. Nowadays, in her role as Technical Leader of AM Research, Lee is heavily engaged in the firm’s additive manufacturing R&D, and as such, she sees both the technology’s benefits and ‘gaps’ that prevent its wider adoption.

In order to provide just a glimpse into the future of automotive 3D printing, Lee has now agreed to speak to 3D Printing Industry, as she prepares to deliver a keynote speech at this year’s Additive Manufacturing Users Group (AMUG) Conference.

“AM has quickly become an essential part of our design and engineering validation process, and continues to be used for more and more functional prototype testing as the technologies advance,” explains Lee. “We now also use AM technologies for the direct production of end-use parts, both for our manufacturing lines as well as for our vehicles.”

3D printing at Ford: a brief history

Having acquired the SLA 3 during the late 1980s, only the third 3D printer ever made, Ford regards itself as one of the technology’s earliest adopters. Since then, Lee says that additive manufacturing has fundamentally “changed its process for new product design,” becoming vital to the company’s validation efforts, including areas such as fluid flow visualization, fit and finish and wind tunnel testing.

Much of this work takes place at the firm’s Advanced Manufacturing Center (AMC) which now not only houses SLA 3D printers, but FDM, SLS, and sand-printing machines. At the AMC, Ford’s team works towards verifying the feasibility of printed parts, and determines how to integrate 3D printing into the factory, as well as validating process quality.

According to Lee, her team “works hand-in-hand” with colleagues at the AMC, in addition to helping develop new materials, processes, and designs capable of being scaled so that they can support wider production. While much of the knowledge around this cutting-edge R&D tends to stay in-house, Ford does occasionally provide a glimpse into related projects, like its truck part 3D printing initiative.

In the past, the firm has also worked with DLS 3D printing specialist Carbon, and it partnered with HP last year to develop a means of recycling 3D printing waste into Ford truck parts. On the subject of sustainability, Lee explains that it’s now of the “utmost importance” to the company, and it’s currently working on ways to reduce the energy, material, and other waste associated with its 3D printing activities.

“This includes the recycling of waste streams and 3D printed prototype parts, among other activities, and using them in downstream applications where possible,” said Lee. “Some examples include the recycling of waste AM powder and parts into injection molded applications for our vehicles, as well as researching the use of factory waste from packaging into filaments for prototyping.”

Identifying R&D opportunities

Within Ford’s current setup, 3D printing is a valuable tool, as it both enables it to streamline its new product design and validation process and make operational cost savings and quality improvements. As the firm develops and evaluates materials and processes for functional prototyping or tooling applications, this work also indicates the feasibility of such technologies for use in vehicle part production.

Although Lee didn’t outline specific use cases in this area, she did suggest that 3D printing is now deployed to “support low-volume, high-mix, high-value applications,” which can be particularly expensive to manufacture with tooling.

When it comes to the advances needed to widen the technology’s automotive applications, Lee points out that Ford already uses it to build end-use parts in both its series production and aftermarket support businesses. However, that being said, she also suggests that the cost of current 3D printable alloys remains too high, while polymers still require work in terms of durability and weathering performance.

Specifically, on the metal 3D printing front, Lee says that while titanium has been deployed at scale in the aerospace and medical industries, more focus on heat-treatable low-alloy steels and aluminum is needed by the automotive industry.

More widely, Lee also recognizes the necessity of standardization within the automotive industry and highlights how Fords’ work as part of the US Council for Automotive Research could be vital to achieving this.

“More work in standards development, especially for the automotive sector, is needed to ensure we are able to measure and reduce variability,” added Lee. “Ford has worked with other automotive OEMs through USCAR to publish ‘The Roadmap for Automotive Additive Manufacturing,’ which highlights opportunities and pathways for the more widespread use of AM technologies in our industry.”

AMUG’s automotive-led keynotes

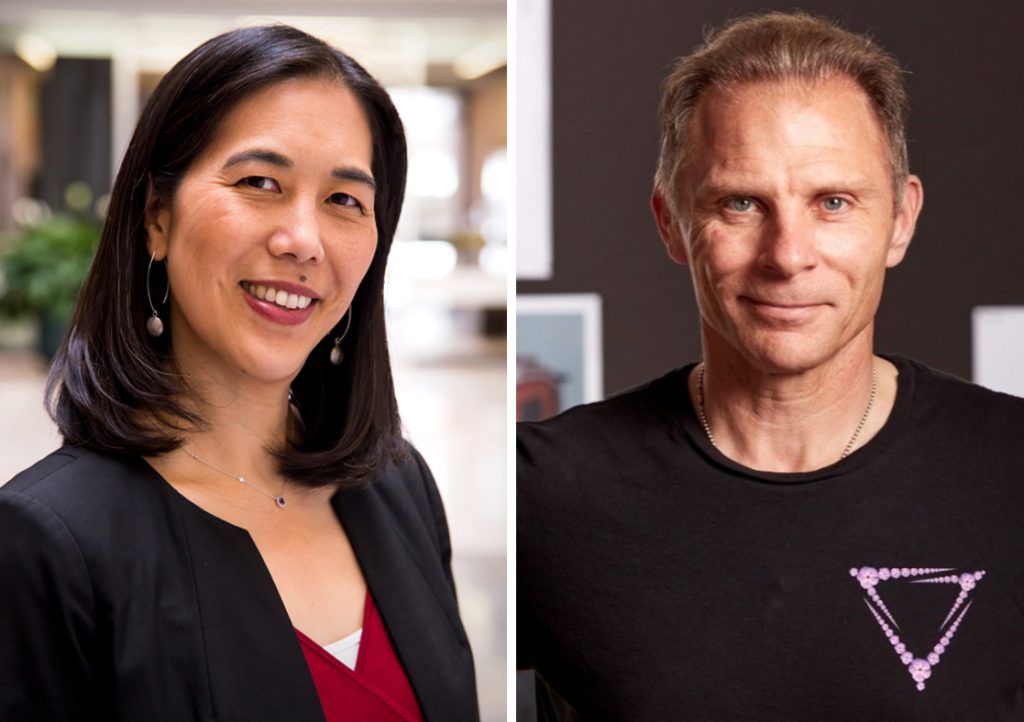

Looking ahead to the AMUG 2022 Conference, Lee explains that she’s excited about connecting with colleagues from around the 3D printing community, and learning about the technology’s latest use-cases, though she’ll have to squeeze this in around plans to speak at the event, alongside fellow keynote speaker Kevin Czinger of Czinger Vehicles.

At the show, Lee says that she plans to start by speaking generally about the “influence the automotive industry has had on the manufacturing landscape,” before delving into the future of production in the industry, covering “where additive manufacturing can play today” and where she “sees opportunities for tomorrow.”

As well as listening to Czinger and Lee’s keynotes, conference attendees also stand to gain access to 150 presentations, discussions, workshops, and hands-on sessions. Fans of the AMUG Technical Competition will be able to check out the contest too, while the ever-popular DINO Awards return for this year’s event, as does the Innovators’ Showcase, which last year featured EOS’ Dr. Hans Langer.

Those interested in attending the AMUG 2022 Conference can still register, and if they sign up before March 11, 2022, they can take advantage of a 27% registration fee discount, with the fee covering tickets to all of the above plus a variety of off-site gatherings, networking receptions and catered meals.

Prospective attendees can use the AMUG online registration form to apply now.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Ford F-250 Super Duty. Photo via Ford.