The 2022 AMUG Conference officially got underway with a sprint through the labyrinth beneath the Chicago Hilton tonight.

For those unfamiliar with the event, the AMUG Expo is compressed, both in terms of the booth space and time allocated. It opens on Sunday afternoon and closes for general exhibitors on Monday. While not prohibited from launching new 3D printers, software, 3D scanners, or materials, many marketing teams choose the wider audience, and bigger booths, available at next month’s RAPID in Detroit. But the expo isn’t really the primary function of the AMUG conference, plus products launched here do have the advantage of being seen by a very select audience: remember this event is not open to the general public.

That being said, there are several launches, and quite a lot of previously unpublished information coming up in this article.

Addressing a market need

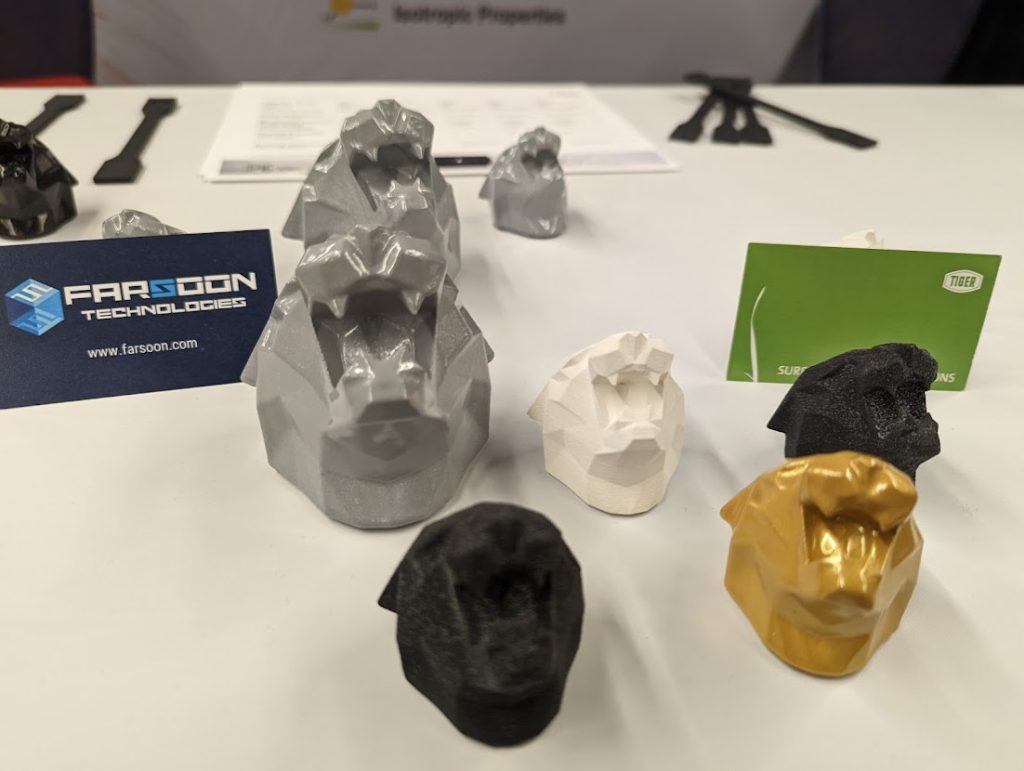

One of several insights gained from our recent State of Resin 3D Printing Survey was widespread dissatisfaction with a number of categories of functional materials. Materials marketed as flame retardant in particular caught smoke. Tiger Coatings was founded over 90 years ago, and was one of the first enterprises to offer powder coatings – and hopes to provide a solution.

In the 1970s, the company developed the RAL color swatch for matching powder coatings, a standard similar to the Pantone Matching System. Tigital 3D Set thermoset materials from Tiger, are post-processing solutions for SLS 3D printers and CBAM systems i.e. Impossible Objects. The company claims that with their post-processing material flame retardant up to UL 94 V0 is possible.

Australia’s SPEE3D have several examples of the capability of their cold-spray additive manufacturing systems to put down a significant amount of metal in a short space of time. An 8kg solid copper hammer printed in 90 minutes was on display. For RAPID, SPEE3D will be 3D printing metal on the trade show floor. Specifically, a demonstration of how the Australian Army additive manufacturing field tests are conducted will be available to visitors.

AMFG is currently in the process of relocating from the UK to the USA. AMFG’s Sven Hinrichs is a first-time attendee and says of the event, “It’s brilliant, but a bit strange!” AMFG hopes to address three sweet spots, “mass production at scale, traceability and connectivity.” On the question of data security, specifically preventing unauthorized 3D printing of a file, Hinrichs highlights the Secured Distributed Additive Manufacturing initiative by a Netherlands-based alliance. Control here will be gained by “watermarking” files with serial numbers, that while not preventing printing do permit audit and investigation work, and so may serve as a deterrent.

Visitech may not be a name familiar to everyone. However, its DLP scrolling lithography technology can be found in industrial 3D printing systems where high throughput and low cost are required. Adam Kunzman is the CEO of Keynote Technologies the US distributor for Norway’s Visitech, a company he describes as “the power behind the projection industry.”

Kunzman does not reveal the names of the companies using Visitech systems, however, he explains that one of the main challenges working with Direct Image Sintering is tuning the systems to the process, or “twisting the knobs behind the scenes.” In the future the company expects its subsystems to be used for powder bed fusion AM.

For Azul 3D, the AMUG Conference is all about applications with throughput remaining a highly valued asset. “How are you going to mass production without the materials your customers want?,” says Azul’s Chief Revenue Officer Tuan TranPham. This solution is customized materials. In particular requests for flame retardant materials are increasing as are requests for materials that do not degrade with environmental exposure, as CEO Cody Petersen puts it, “People are getting killed on UV.”

Catching a delegate’s attention without recourse to the lavish booth spaces at shows when the conference is not the main attraction can prove challenging. During my time at the Tech Met Inc. booth and number of people stopped to find out just what was going on with this sign:

The answer? Tech Met offers post-processing for metal parts using a chemical milling system that takes off the rough high points. Oh, and Tech Met was also giving away branded “dog poop bag dispensers” – truly a 360° marketing campaign.

Coming up

If I were a gambling man I would not bet against Todd Grimm taking issue with the rampant use of the term “industrial” as an adjective when he gives his traditional early conference take on the tech. “Diamond Sponsor Insights and Highlights” will be in the first session on Monday during the 8:00-10:00 AM slot. While tight-lipped on what to expect in his presentation, highlights from the AMUG event so far include a visit to the DMG Mori facility on Sunday for a first look at the LaserTEC 3000 DED Hybrid AM system.

A couple of product launches at the AMUG 2022 Conference include the launch of Titanium and Aluminum metal powders from Höganäs. Nexa3D is launching the NXE200 resin 3D printing system. The NXE200 is priced at under $50,000 is a smaller version of the NXE400. Nexa3D also reports that the XIP went on sale on 1st April at $6000 and the first units will arrive in June.

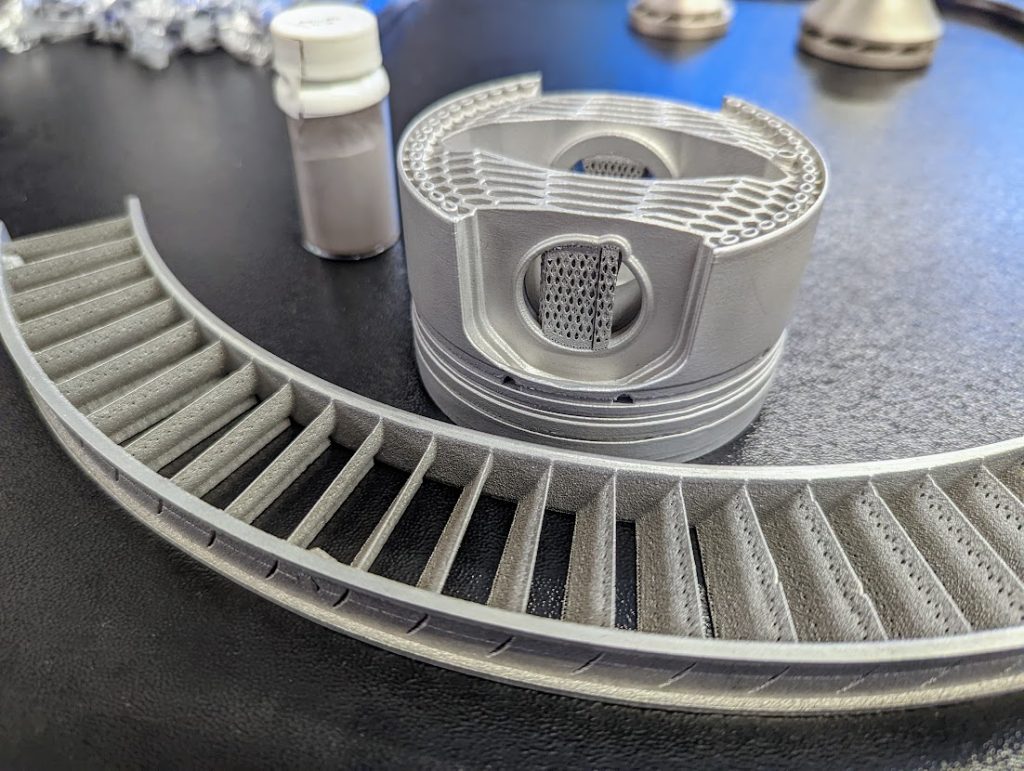

Back to Aluminum and Valimet is tackling the material Chris Adam, President, says “only so many people can print with it.” The material is expected to scale within five to ten years, and R&D is underway to develop parameters. “It’s coming,” says Adam. When asked why Aluminium, Valimet highlights the lightweight piston head and turbine blade on display at their booth.

Staying with metal, Meltio is in Chicago after recently opening up a Florida office. Meltio systems are suitable for very large parts, up to 100kg. This could include heavy-duty repair work, for example in mold making. A spool of 316 Stainless Steel weighs 15kg, costs approximately 20 dollars per kilo, and can be fully 3D printing in around 30 hours.

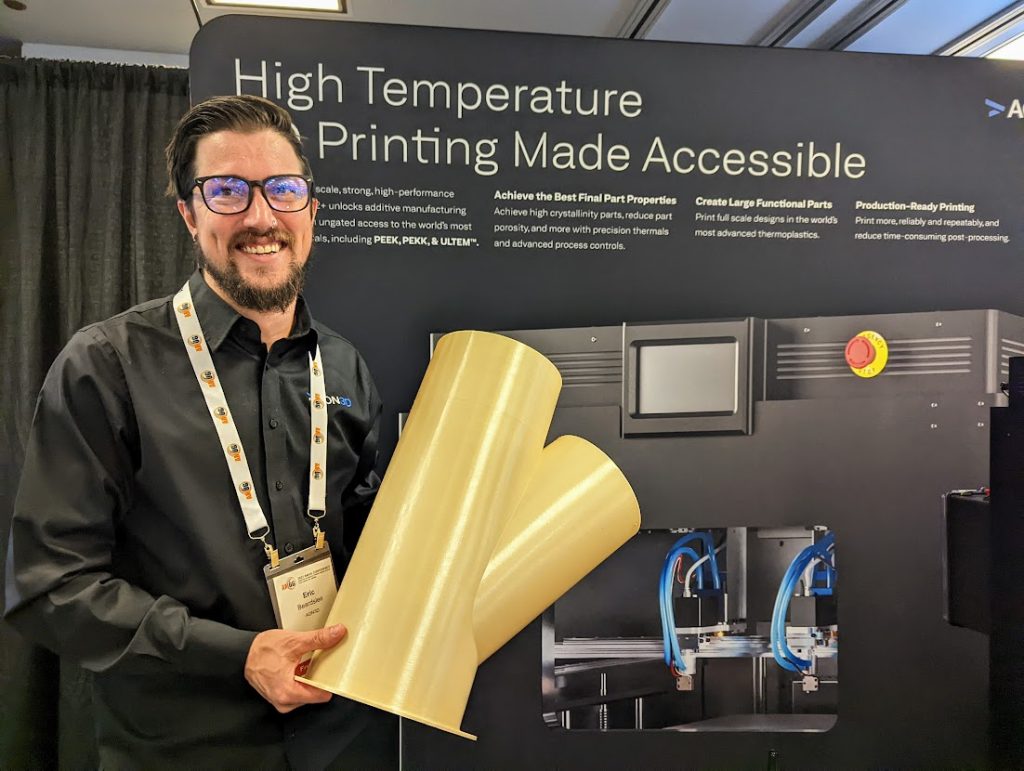

AON3D is really picking up the pace, especially with a new CRO and moving towards true plug and play usability. The company’s 3D printers have been used to create housing for the first commercial payloads destined for the moon. The “moon boxes” are scheduled for launch sometime during the early summer, payloads will include earth taken from Everest. 3D printing in Carbon Fiber PEKK gives half the mass of a metal object with the same strength.

DyeMansion’s collaboration with Bauer Hockey will be commercially available in the Fall. These ice hockey helmets use 3D printed lattice structure, and while currently available to elite athletes custom fitting will be available to all. The material is certified by CSA, HECC, and ISO. Thierry Krick, who heads Bauers advance group believes around “300 retailers will have a 3D scanner in-store. We have only dipped our big toe in the industry. Optimization will be way better. “ Bauer is using nTopology’s nTop software to generate the lattices.

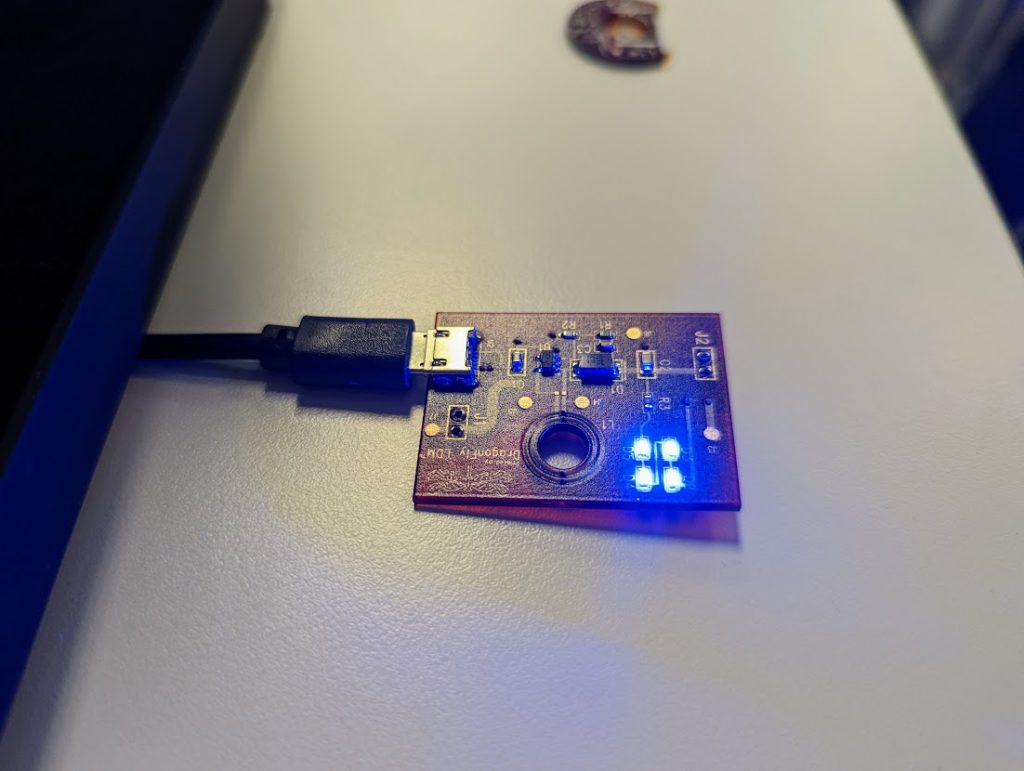

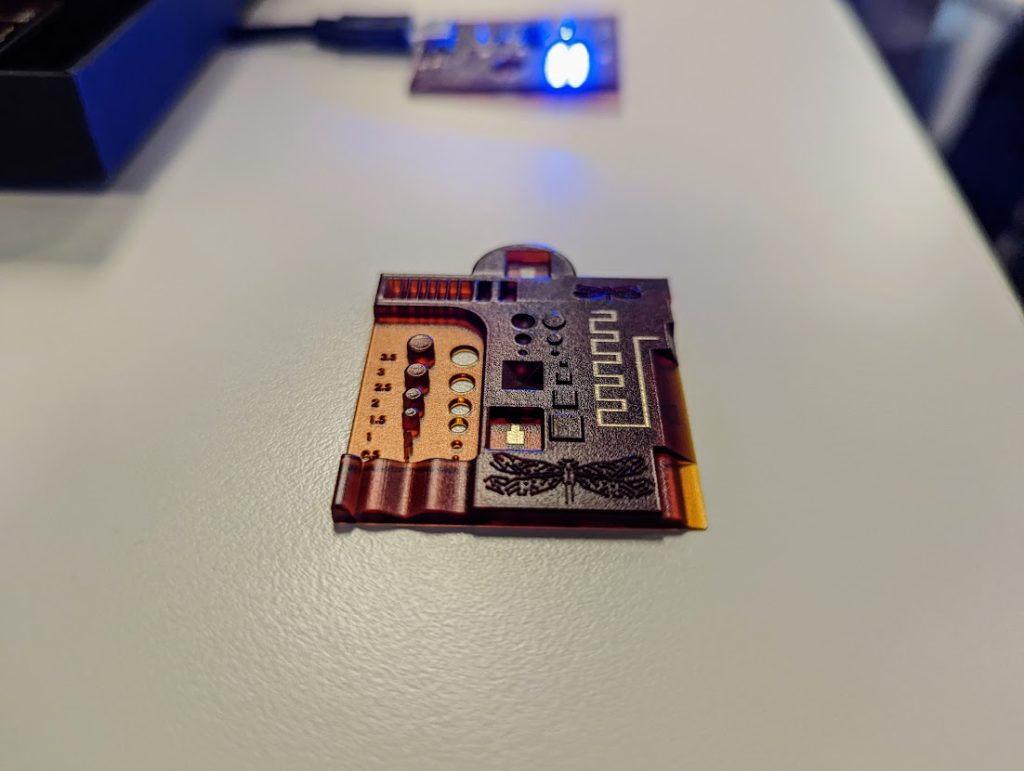

Nano Dimension is exhibiting for the first time at the AMUG Expo. The 3D printed electronics company wants to raise its profile in the additive industry. The parts printing on the DragonFly 4 has certainly evolved impressively since earlier iterations.

Fabweaver might be an unfamiliar name. But the company is not a newcomer, essentially this is Sindoh’s approach to the professional market. With a price point of $10,000 and offering “industrial level” FFF 3D printing in ABS, ASA, and other materials the company is targeting the middle range of users.

This is just a small sample of the AMUG Expo. 3D Printing Industry will be in Chicago for the whole week – so make sure you subscribe to the 3D Printing Industry newsletter for the full coverage.

You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the AMUG Conference 2022 New Members Reception. Photo by Michael Petch