Fast Radius, an advanced digital manufacturing company based in Chicago, has raised $48 million in Series B funding led by the United Parcel Service (UPS) to expand its production capabilities worldwide. In doing so, the company will further develop its software, the Fast Radius Operating System (FROS), which helps customers to integrate additive manufacturing for new product development.

This funding, of which Drive Capital was a strong contributor, will also expand production sites outside of the U.S as well as its sales team. Pat McCusker, COO of Fast Radius told 3D Printing Industry, “FROS helps customers identify potential applications, conduct engineering, and economic evaluations, accelerate new product development, and ultimately manufacture industrial-grade parts in Fast Radius factories at scale with the latest additive technologies.”

“It enables our engineers to work with customers to identify potential applications and makes possible the development of potentially thousands of prototypes until the right part or product is created.”

“This additional funding will allow us to further expand our partnerships with leading global companies across aerospace, consumer, industrial, medical, and automotive verticals.”

Accelerating additive manufacturing

Founded in 2015, Fast Radius provides additive and traditional manufacturing solutions to its customers, fostering product development and supply chain digitization. With its ongoing partnership with UPS, 3D printing on demand services have been established globally, enabling a 24-hour turnaround for part manufacturing and shipping.

With UPS, Fast Radius offers CNC machining, injection molding, and additive manufacturing processes covering FDM, SLA, SLS, DMLS, and HP Multi-jet fusion. In a previous interview with Lou Rassey, CEO of Fast Radius, it was said that the company holds the largest deployment of Carbon 3D printers in the Western Hemisphere, and is one of HP’s largest production partners.

When asked about how this funding will push metal additive manufacturing in particular, McCusker said, “We will be scaling up our metal capabilities this year. As part of that initiative, we will soon be announcing a partnership with Desktop Metal, about which we’ll have more details to share in the next few weeks.”

Expanding in Asia and Europe

In 2018, Fast Radius was selected by the World Economic Forum (WEF) and the McKinsey & Company Initiative on Shaping the Future of Production as a Fourth Industrial Revolution “Lighthouse”. This project aims to develop an international learning platform for manufacturers seeking to leverage additive manufacturing and other processes under the umbrella of Industry 4.0.

McCusker adds that Fast Radius’ expansion as part of this $48 million fundraising will lead to facilities into markets in Asia and Europe. Also participating in the Fast Radius Series B financing were investors Jump Capital, Skydeck, and Hyde Park Venture Partners.

Vote for the best 3D printer for 2019 3D Printing Awards.

For more information on the latest trends in additive manufacturing subscribe to our 3D printing newsletter and follow us Facebook and Twitter.

We also have jobs in the industry, visit our 3D Printing Jobs board to find out more.

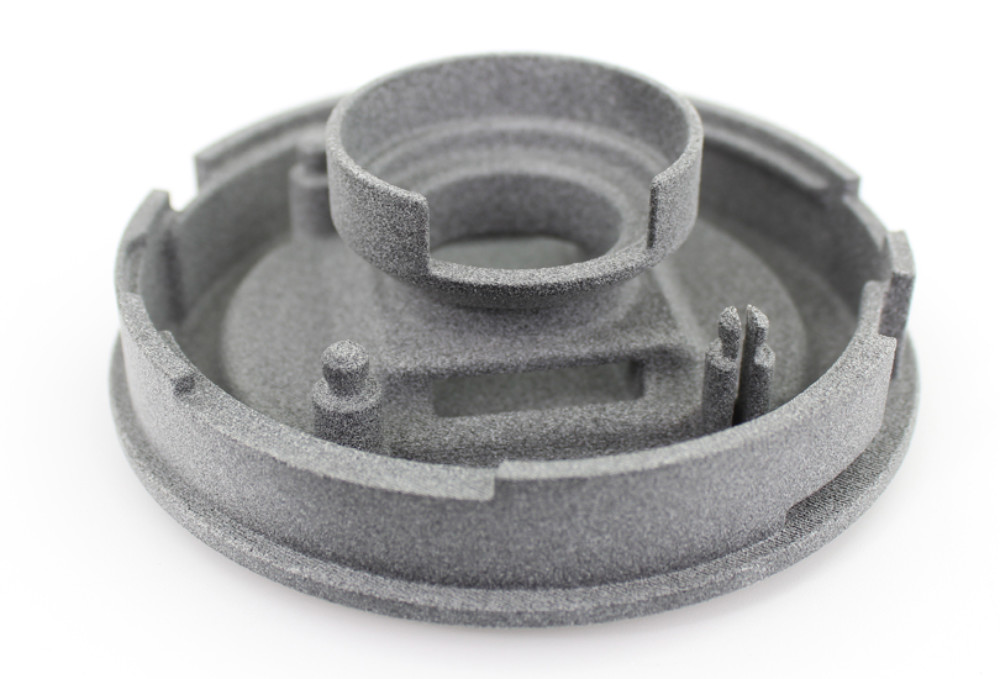

Featured image shows industrial-grade 3D printed parts. Photo via Fast Radius.