Leading American technology company Aerojet Rocketdyne Holdings, Inc. (NYSE:AJRD) has added a company to its 3D printing portfolio. Additive manufacturing service provider 3D Material Technologies (3DMT), headquartered in Daytona Beach, Florida, has been bought by Aerojet from its parent metal stamping company ARC Group Worldwide, Inc. Full terms of the deal remain undisclosed. Aerojet Rocketdyne has stated “both the purchase price and ongoing financials are deemed immaterial to the business.”

Eileen Drake, President and CEO of Aerojet Rocketdyne Holdings, Inc., commented, “The addition of 3DMT’s capacity and expertise in metal alloy additive manufacturing expands our range of products and services in the space and defense markets.”

“As we look to the future, additive manufacturing will continue to play an important role in lowering costs and production timelines. This deal allows Aerojet Rocketdyne to broaden its application of this revolutionary technology.”

“We respect the long-standing reputation for quality and customer focus that 3DMT has built in the aerospace industry and we are thrilled to welcome them to our company.”

Additive manufacturing at Aerojet Rocketdyne

Established in 1915 as the General Tire and Rubber Company, Aerojet Rocketdyne Holdings, Inc. is a technology manufacturer in aerospace, defense, and a real estate business. As part of the former, the company is the parent of Californian rocket and missile manufacturer Aerojet Rocketdyne.

A leading manufacture of rocket engines Aerojet Rocketdyne prides itself on the application of additive manufacturing technologies to, as Drake states, “reduce costs and improve the efficiency of proven engines.” In 2014, the company successfully test fired the “Baby Bantam,” a 5,000-pound-thrust engine fabricated entirely using 3D printing. Beyond this, 3D printing is also used at the company to make critical parts of the AR1, RL-10, and the RS-25 for NASA’s Space Launch System (SLS) project, as well as MPS-120 CubeSat and NASA’s Orion Crew Module propulsion components.

Inside 3DMT

3DMT is an on demand manufacturer service provider with metal additive, polymer 3D printing, CNC machining and MIM capabilities. Founded in 2013, the company employs between 11 and 50 employees within a 28,000 square ft. facility in Daytona Beach. Following its acquisition by Aerojet Rocketdyne, 3DMT will continue to operate at the same site. Aerojet Rocketdyne nearest sites to 3DMT are in West Palm Beach and Orlando, between which the company employs around 650 people.

In a guest article for 3D Printing Industry, investor Gary Anderson visited 3DMT in 2014. At the time, it was believed to be one of the largest metal 3D printing capabilities in the world, housing a number of Concept Laser machines.

Vote for your Aerospace Application of the Year in the 2019 3D Printing Industry Awards. For all of the latest 3D printing aerospace and business news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Join 3D Printing Jobs to find your next opportunity.

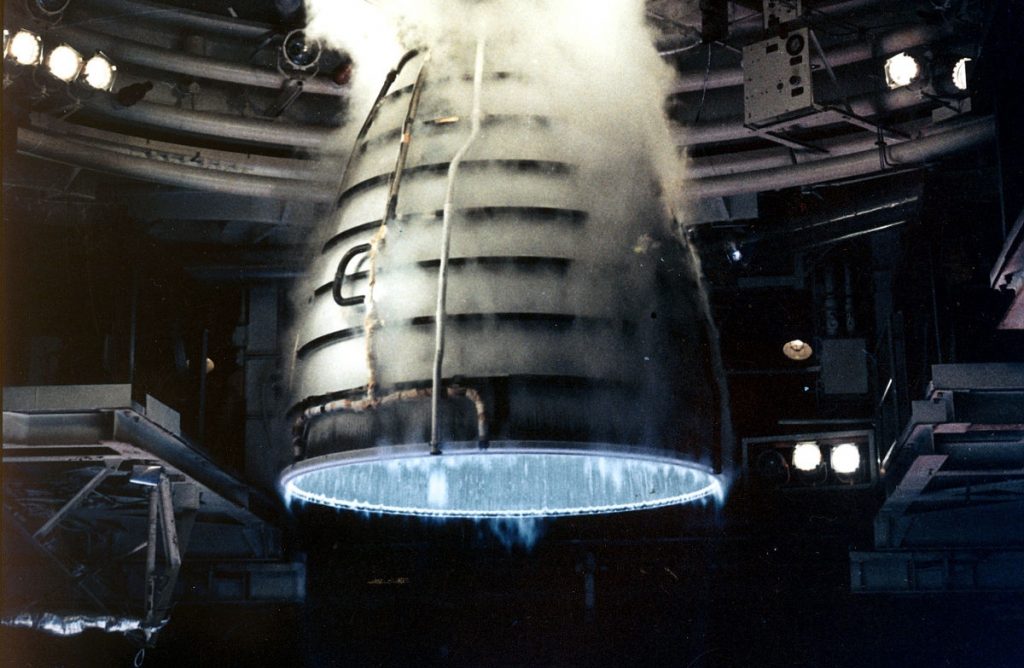

Featured image shows Aerojet Rocketdyne testing the AR1 preburner at NASA’s Stennis Space Center. Photo via Aerojet Rocketdyne.