Electrochemical Additive Manufacturing (ECAM) is a new method of low-cost metal fabrication in development at Imperial College London (ICL). Expanding on a presentation of the technique from Advanced Materials Technologies in August 2017, the ICL team has recently published a paper on ECAM’s potential for 4D printing.

Dr. Billy Wu is one of the three corresponding authors of the new ECAM article for Scientific Reports. In his tenure as Senior Lecturer in Energy and Manufacturing at the ICL Dyson School of Design Engineering, Dr. Wu also co-leads the university’s Additive Manufacturing Network (AMN). 3D Printing Industry speaks to Dr. Wu to learn more the ICL’s team’s vision for self-assembling metal.

Laser-free metal additive

ECAM is a fabrication method based on the principles of electroplating, commonly used to add more valuable metal layers to pieces of jewelry. It uses a liquid solution of electrified metal ions as a feedstock, creating solid layers of metal upon contact with a negatively charged copper bed. Common materials used for this process, as explained by Dr. Wu, include “copper, zinc, nickel and tin,” though it is also possible to use alloys. “Essentially,” he adds, “any metal that can be electroplated can be used in the ECAM process.”

One of the benefits of an electrochemical process over other metal fabrication techniques, that rely on laser power for example, is that it becomes much easier to fuse multiple metals together. In turn, this allows scientists to experiment with different material combinations, and explore possibilities otherwise impossible in single metal structures. One such possibility, is the creation of 4D printed metal objects, i.e. objects capable of transforming after fabrication. As stated by Dr. Wu, this is one the key developments of the team’s most recent publication, “we have now demonstrated the ability to print with multiple metals. […]”

“This therefore, enables us to design 4D structures which are able to move when actuated with temperature due to the difference in thermal expansion coefficient of the 2 different metals.”

4D printing for higher temperature applications

As Dr. Wu rightly points out in our conversation, 4D printing is typically limited to polymers, e.g. ETH Zurich’s deployable trusses and the self-folding tulip at TU Delft. “However,” he adds, “these [polymers] are limited by their operational temperature.”

Pinpointing the driving factor behind his team’s latest research, Dr. Wu adds:

“With a 4D metal approach, higher temperature operation can be achieved.”

Furthermore, enhancing the original purpose of ECAM’s development, “Passive actuation simplifies the design of complex items making them cheaper, more reliable (fewer parts) and more energy efficient.”

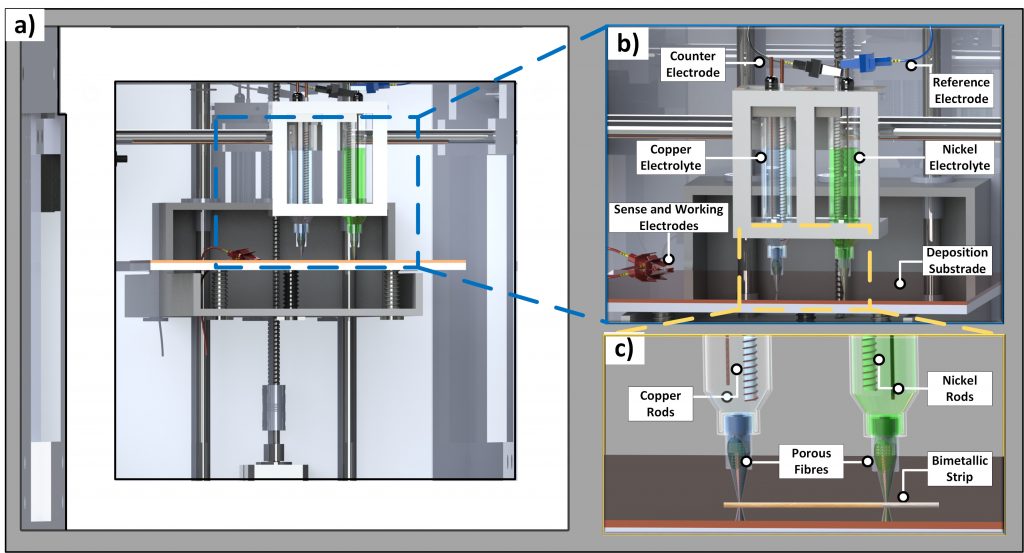

To enable multi-metal 4D printing, the ICL team simply added to its existing ECAM system from 2017: “Through the simple addition of another print head with a different electrolyte copper/copper sulphate and nickel/nickel sulphate,” explains Dr. Wu, “we are able to selectively deposit different metals in different locations.”

Self-switching lights

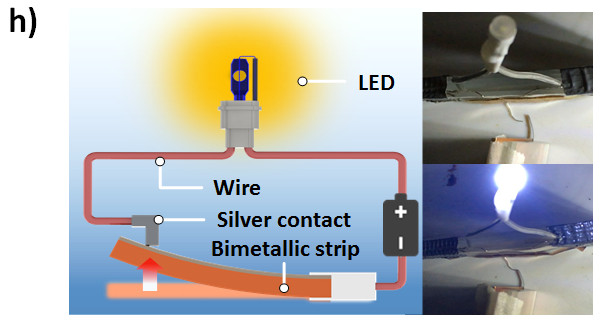

To demonstrate ECAM’s new capabilities, the ICL team 3D prints a selection of self-assembling structures, including “a bimetallic strip which controls a circuit which turns on a light.”

Further describing this device, Dr. Wu says, “With this we can therefore program into a structure the ability to turn things on and off without external control. For example we might make a valve which constricts flow if the temperature gets too hot. Or make structures which self assemble when heated.”

The full results of this experimentation are published open access in the article “Multi-metal 4D printing with a desktop electrochemical 3D printer” which was co-authored by Xiaolong Chen, Xinhua Liu, Mengzheng Ouyang, Jingyi Chen, Oluwadamilola Taiwo, Yuhua Xia, Peter R. N. Childs, Nigel P. Brandon and Dr. Wu.

For more of the latest 3D printing research subscribe to our 3D printing newsletter. You can also join us on Facebook and Twitter. Looking for a job in the industry? Visit our 3D Printing Jobs board.

Featured image shows an illustration of ECAM-made heat-activated 4D metal samples. Image via Scientific Reports