The International Data Corporation (IDC) has released ten predictions that will significantly impact the 3D printing market over the next three to five years.

As a result of its worldwide research, one of IDC forecasts attributes ongoing trade wars and manufacturing automation to a 40% drive in additive manufacturing implementation by discrete manufacturers worldwide by 2021.

Furthermore, the IDC analysts believe that by 2022, 75% of all new 3D printers will support new materials with properties like gel and rubber, thus driving $2 billion in new spending related to 3D printed products.

The race to innovation

Headquartered in Framingham, Massachusetts, IDC employs more than 1,100 analysts located in over 50 countries. With 49% of its analysts active in emerging markets, the company boasts global, regional and local expertise on technology and industry trends and conducts primary demand-side research with more than 350,000 end users surveyed annually.

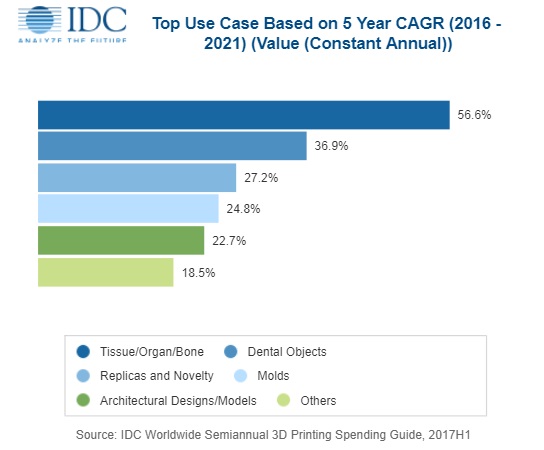

Earlier this year, IDC updated its Worldwide Semiannual 3D Printing Spending Guide forecasting market-wide spending on additive manufacturing throughout 2018 to be approximately $12 billion.

The IDC FutureScape: Worldwide 3D Printing 2019 Predictions, headed by Keith Kmetz, the Program Vice President of IDC’s Imaging, Printing & Document Solutions programs, offers guidance for managing the forecasted future of additive manufacturing regarding IT investments and implementation strategies.

The future of additive manufacturing

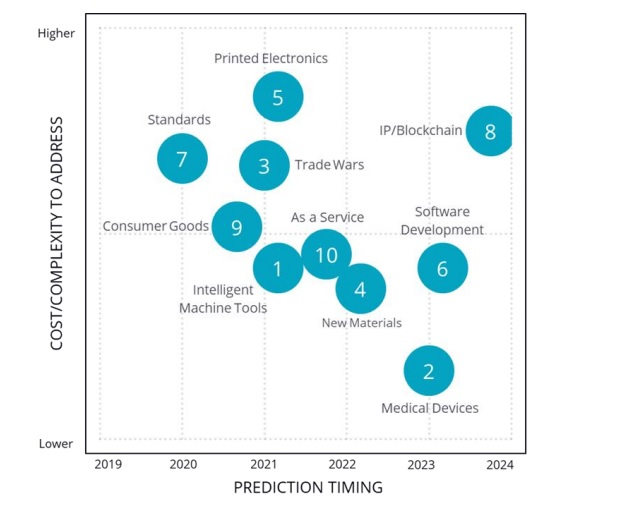

The IDC 3D printing predictions have been categorized under different themes as seen from the graph below; the forecasts are also numbered for identification. The first (1) prediction states that by 2021, 40% of the top 2,000 manufacturers will utilize 3D printing combined with intelligent machine tools to optimize material usage, thus reducing waste by at least 25%.

The second (2) claims that despite rapid ongoing advances in 3D bioprinting, patient-specific durable medical devices will account for 80% of the commercial healthcare 3D printing market in 2023. As previously mentioned, analysts predict that (3) trade wars and automation will have driven more than 40% of discrete manufacturers towards 3D printing by 2021.

Furthermore, within the healthcare sector, (4) by 2022, 75% of all new 3D printers will support new materials with properties like gel and rubber, thus driving $2 billion in new spending related to 3D printed products.

Moreover, it is estimated that (5) by 2021, 30% of electronics manufacturers worldwide will have incorporated 3D printed electronics and 4D printing to address the demand of stretchable and flexible electronics amid growing IoT adoption. Before 2023,(6) 50% of industrial and professional 3D prints will be influenced by generative design, topology optimization, and marketplace software.

Within advanced industries, (7) by 2020, 3D printing advances will have driven more than 50% of aerospace manufacturers worldwide to partner with industry-standards development groups to formalize the use of 3D printing. Also within software developments, (8) by 2024, 35% of 3D printer CAD files will be protected by blockchain as companies look for decentralized low-cost options to protect digital IP from theft and loss.

Looking at the consumer markets, it is believed that by 2021 (9), every major international footwear manufacturer will produce, market, and sell an athletics shoe line that is nearly 100% 3D printed. Finally, the tenth prediction (10) forecasts that by 2022, 20% of 3D printer equipment manufacturers will have adopted an “as a service” model as the primary avenue to reach customers and maximize their market potential.

Make your nominations for the 2019 3D Printing Industry Awards here.

Also, for all the latest 3D printing news, subscribe to our free newsletter, follow us on Twitter and like us on Facebook.

To commence your career in additive manufacturing or post new opportunities, join 3D Printing Jobs.

Featured image shows a depiction of advanced and connected technologies. Image via IDC.