At present the combination of additive and subtractive manufacturing, known as hybrid manufacturing, has been primarily for professional use. However, research shows how efforts to bring this technology to the desktop are progressing, especially for education. The idea is that additive manufacturing, while being perfect for a variety of functions, is not neccessarily a ‘fits-all’ solution and can complement, rather than replace tradition subtractive manufacturing. This combination of the two may provide the best of both worlds. This is not a new concept, it is used and has been developed by a number of companies, such as DMG Mori and BeAM for industrial clients, yet few enterprises are focusing on bringing these techniques to the desktop.

DMG Mori and BeAM are both showcasing their latest hybrid offerings at Formnext.

Recent developments in the hybrid AM space a discussed in new research from the University of California, Davis (UCDavis) and published in the paper Development of a Desktop Hybrid Multipurpose Grinding and 3D Printing Machine for Educational Purposes. The research was conducted by a group of graduates and undergraduates in a summer camp program at the university keeping the end-user, a hobbyist or student, in mind. The research also has an overlap with recent news that Fab Labs continue to grow in popularity and multiple universities are developing their own MakerSpaces.

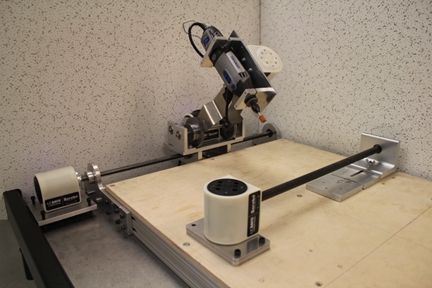

The Modular Hybrid Desktop Machine from UCDavis uses a Linkbot modular robot design. This is a concept developed at UCDavis by a spin-out company called Barobo. The company are developing these modular robot components with education also being the primary focus. These components are easy to use and to set up – hence the focus on students and education. The machine is small in size with the use of modular components meaning it is ideal for desktop, and it also has a small energy footprint. In addition to this, the current conception of the machine uses a Wii nunchuk to help control the rotational velocity of the linkbot motor modules. This further emphasizes the idea that these machines will be user friendly.

The paper, published in Procedia Manufacturing Vol. 5, talks heavily about the impact of this hybrid technology on DIY use, in addition to the main focus on its educational impact. The paper focuses on the development of a desktop hybrid machine which involves mainly grinding and wire extrusion. As the paper is quick to highlight, the machine is in its first iteration and thus there is room for improvement and also room for future components of the device to be printed themselves. The research continues with the overall aim of bringing hybrid manufacturing to rural areas. It would certainly be a handy machine to have in one of the world’s 1000 Fab Labs.

Featured image shows The Modular Hybrid Desktop Machine from University of California. Image via MASTeR Lab.