3D printing has been around for more than 30 years already and sparked excitement among the public and futurists alike. In an episode of ABC’s Good Morning America from 1989, stereolithography is introduced to the audience as a technology that will dramatically change the way we manufacture products. Replace the technical expression “stereolithography” with “3D printing” and the rather odd hair style of the show’s host and this report could still air today.

For one, this is due to the fairly high value of a design itself, compared to the material price. This design premium enables entrepreneurs to operate with manufacturing prices that are far higher than the usual mass-production unit cost. Some of 3D printing’s advantages, like quick product development and the possibility of producing items on-demand, caters to the industry. Like the first private computers in the early eighties, 3D printing is about to find its first meaningful large-scale applications that might catapult it to become truly mainstream. Jewelry could be this large-scale application.

For others, 3D printing could mean liberation. Producing jewelry used to be expensive and often frustrating for independent designers. To be able to keep up with the big guys, you needed money – a lot of it. In order to stay competitive, large orders needed to be placed abroad and pre-financing was put at risk, with the hope, to reap the rewards during trade fairs half a year later. This took a good network, even better nerves, and quite some luck when it came to production-quality and customer demand.

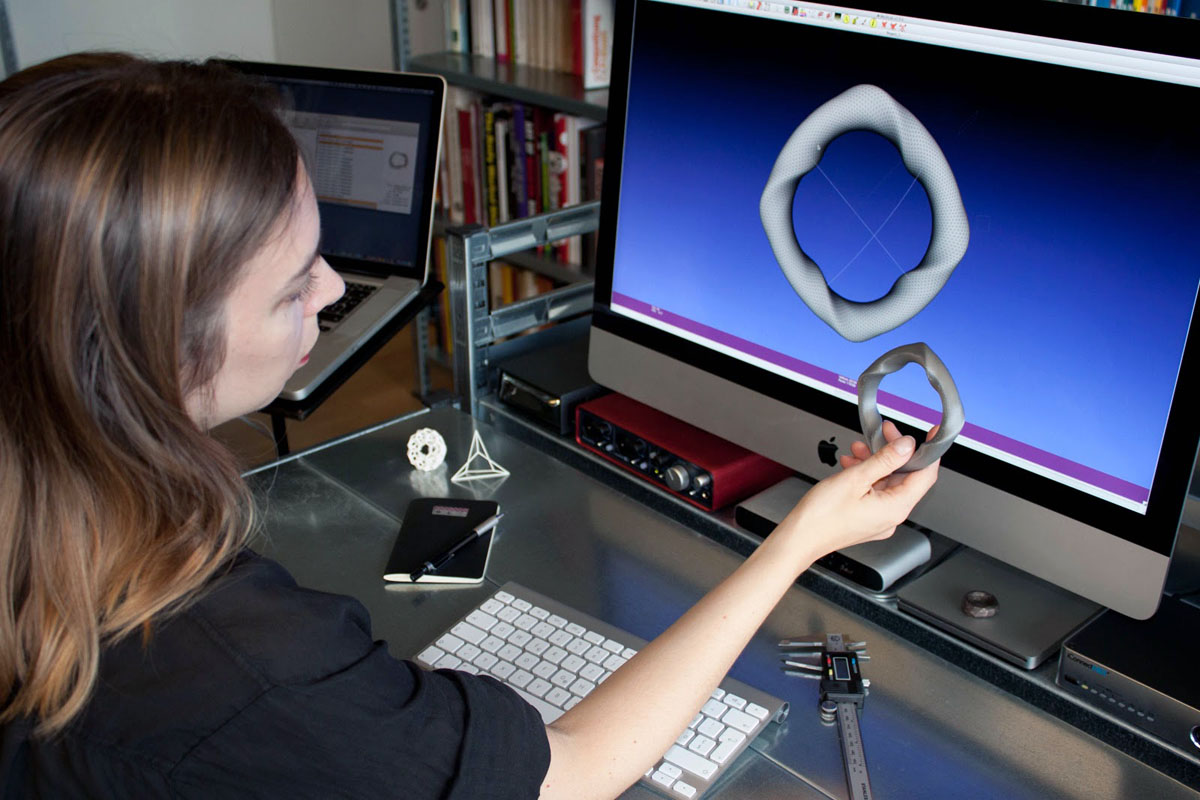

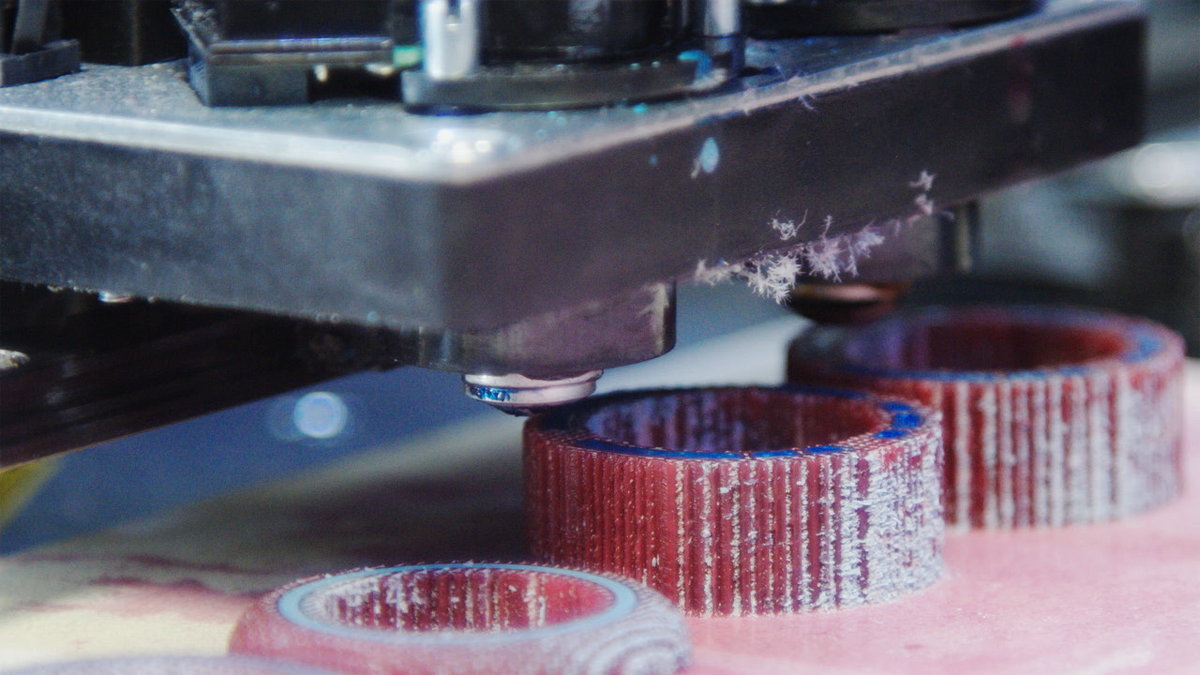

3D printing is changing the economics of the jewelry design market drastically. Independent designers are now able to bring their designs into the world without having to invest a lot of money first. You have a good idea? Create a CAD file and have it printed directly. Service providers are already hitting the market, that provide a full list of related services, ranging from mere production to quality assurance, packaging, branding, sales, and even processing and customer care. The designer can now cherry-pick what suits his/her talents best – s/he might decide to control the whole process or simply focus on designing great products. Giving the designer a whole new avenue to explore, there are plenty of new objects to be discovered. 3D printing enables shapes with undercuts, complex structures, and even directly functional parts.

But something else becomes possible, too: The connection between local and international. Because the CAD files can be sent via email and the production can be done locally, you have designers in Hawaii selling to the rest of the world, and the other way around. The actual production can stay in areas close to the actual demand. The orders come in and can be printed on demand; you don’t have to stock big bulks of products, so overproduction might soon be a thing of the past.

For the big brands this is quite the challenge. To receive as-low-as-possible production costs, big brands make a dangerous pact: Products are ordered months in advance, leaving companies inflexible and vulnerable to rapid trend adaption. That is a serious threat as Zara successfully showed its competitors in the fashion industry two decades ago. With the help of 3D printing, however, the designer can directly react to current developments and micro-trends without having to plan beforehand. S/he can make customisations, test his/her designs and learn to understand what the customer really needs. On-demand production is already as fast as one week – from factory to the customer’s doormat.

Thinking a step further, this digital design is as costly as writing a blogpost. The design takes up a few megabytes and the time of its creator. It can easily be changed, customised, and adapted. Combined with some other trends like self-learning algorithms, an evolutionary approach can produce several versions of the same design, the popular version is further promoted, while the least favorites blend out – its fate is determined by the amount of views it receives.

It is easy to get carried away by the future potential of a technology. However, different from the report that aired in 1989 on Good Morning America, this article describes the current production method being used by a few pioneering companies and ambitious designers alike. Twenty five years might be forever in the life of a hairstyle, but it is only the infancy of a life for a trailblazing technology like 3D printing.