Höganäs AB, the world’s largest producer of powdered metals, has developed a new product venture focused on the areas of additive manufacturing and Metal Injection Molding (MIM).

Called Customization Technologies, the new area will be part of the Höganäs Industrial business, and has been created to meet recent demand for the technical development of AM and MIM .

The relationship between additive and MIM

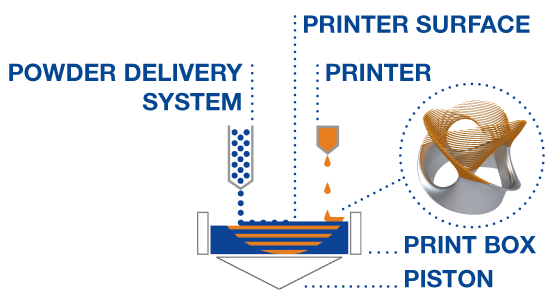

Additive manufacturing and MIM are closely linked by the metal binder jetting process. The MIM process gained recognition in engineering throughout the 1990s. Following this prominence, a number of companies have invented binder-jetting based 3D printing technologies by utilizing the comparatively cheap metal powder used in the MIM process.

Höganäs subsidiary Digital Metal is one such company that has developed metal binder jet 3D printers using MIM powders. By jetting a liquid binder onto the powder that is afterwards sintered from the metal by heat, Digital Metal 3D printers can create incredibly detailed bespoke components, including bespoke busts.

Genesis of strong position in the market

In its new Customization Technologies business segment, Höganäs will work on solutions across entire additive and MIM value chain. Products will include the development of new applications for the technologies, support, market development and global sales.

Customization Technologies will also leverage the expertise of the company’s recent acquisitions of America Makes partner H.C. Starck Surface Technology and Ceramic Powders, and Swedish spherical metal powder producer Metasphere Technology – in an endeavour specifically focused on materials production for AM.

Kennet Almkvist, Senior Vice President of Commercial will be heading up the Customization Technologies segment. “With this new venture,” explains Almkvist, “Höganäs becomes a strong global supplier of products and services within these fields on an international, expanding market.”

Fredrik Emilsson, CEO of Höganäs AB, concludes:

“Höganäs already has a number of successful metal powders in AM and we see further opportunities to grow rapidly within both AM and MIM.”

For 3D printer materials, hardware and software news subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Decide material of the year in the 2018 3D Printing Industry Awards before voting closes.

For all the latest industry opportunities and to advertise your current vacancies visit 3D printing jobs.

Featured image shows a 3D printed sample from Höganäs subsidiary Digital Metal. Photo via Digital Metal