Every so often (actually quite often) I run into 3D printing companies that open up a window into a yet unfamiliar world. With a highly-detailed, four-part, blog entry, Gyrobot – a Swindon, UK-based mechanical design consultancy – just opened me up to one of 3D printing’s biggest consumer promises: the world of custom-made 3D printed insoles.

Not to say that I had not heard or thought about 3D printed insoles before. There are many professional grade experiments and investments being made in this sense. Gyrobot’s blog, however, delves into the very practical aspects of making 3D printed insoles yourself, offering a wide range of open source, freely accessible tools to optimize results.

It all begins with Filaflex’s TPU, and a soft material compatible filament extruder and 3D printer. Gyrobot uses a Witbox and goes as far as suggesting the €2,995 Lewihe 3D printer, which, as Michael had reported some time ago, is particularly focused on the use of flexible material.

Gryobot’s goal is to show that “anyone without any qualifications, experience or knowledge in the podiatry field (that’s me) can produce comfortable insoles using a completely free open source tool chain”.

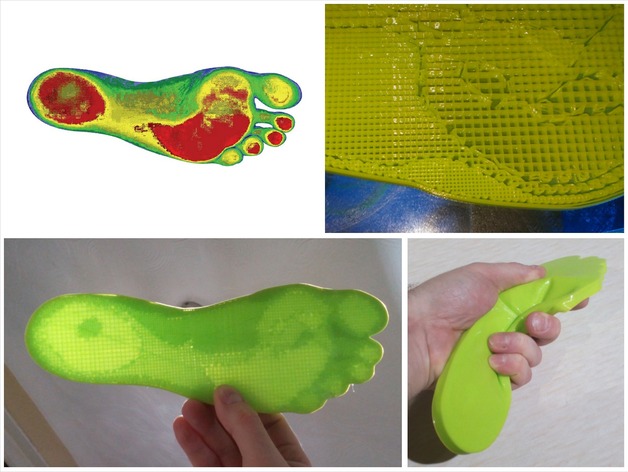

The first “lesson” is on the Open Core Mesh of the insole; that is, the omission of the top and bottom layers of a print to expose the infill structure and, thus, increase ventilation,while reducing material use and time requirements. The options explored include the use of multiple color materials, while maintaining a shape that is still comparable to subtractively or traditionally manufactured insoles.

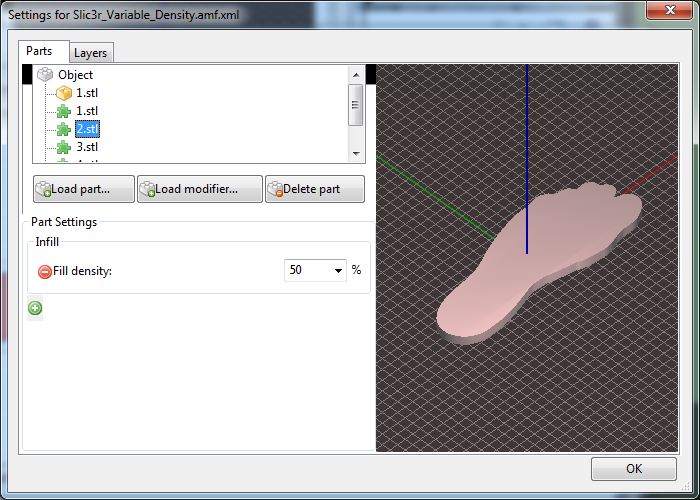

The third blog entry explores customization through 3D scanning and “topological optimization” of the mesh through the use of Slic3r’s later revisions (preferred to software like Simplify 3D, for its open source availability). Slic3r’s “modifier meshes” allow you to modify the infill percentage in selected parts of your still model. This blog entry shows how, even using a single material and 3D printer, a complex structure can be created with differing grades of hardness, according to the individual recipient’s needs.

The final blog entry, yet to be published, includes information on acquiring scanned foot data. Gyrobot says that all you will need is a 5-year-old,flat-bed document scanner and also argues that it is difficult to describe in words just how flexible and comfortable the final result is.

Keeping in mind that this is not a medically certified product, I am fairly certain that there are a lot of people who can’t wait to find out more or to download the open source insole and all the relative information from Thingiverse.