3D measuring and testing specialists GOM GmbH have launched an international competition inviting proposals for the inspired use of the ATOS desktop 3D scanner. For the competition a student’s lab experiment could involve anything from industrial measuring to product design, and 3DPI certainly see this competition as having great potential for the reverse engineering and rapid prototyping of a product.

Inciting interest in 3D metrology

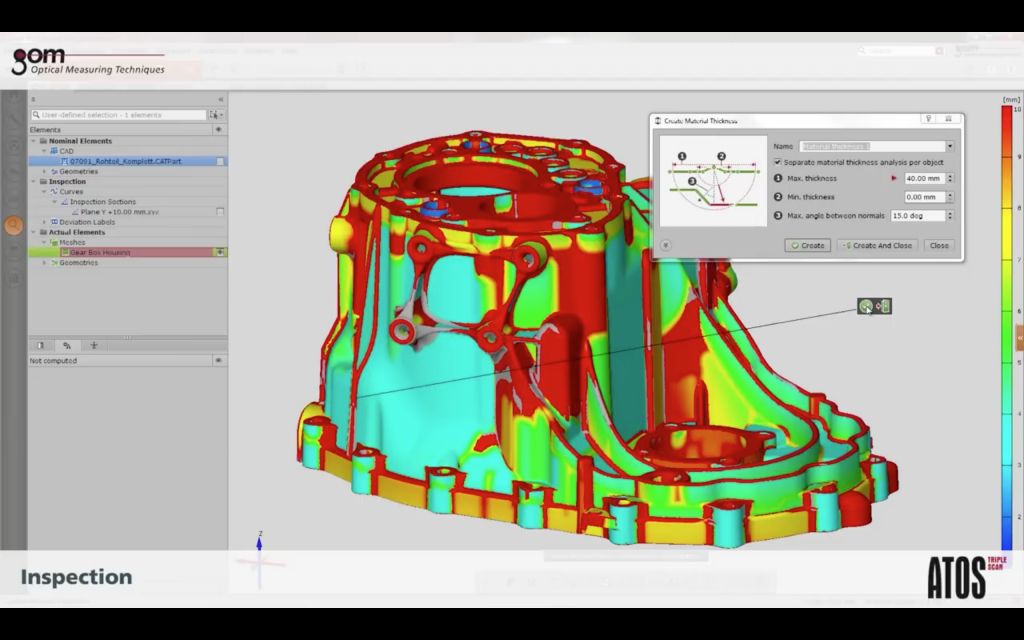

3D scanning for industrial metrology adds another level to figuring out how things work. Instead of scrutinising every inch on an object by eye alone, a 3D scan gives a heightened vision of the chosen object that is capable of being digitally manipulated, annotated and iterated in computer software. It also gives engineers and designers a base to work from, rather than having to redesign, say a car part, each time it needs to be changed.

This ‘digital eye’ of a physical object, forms the basis for the Smart Factories of Industry 4.0, as machines are taught how to ‘see’ what they’re working with, and create digital copies shared with the people running the project. If students were to propose a model for how the ATOS could be used in the ‘factory of the future’, it will no doubt attract the panel’s attention.

Cars, planes & turbines

Industrial use cases of GOM Metrology Systems include automotive, aerospace, power, transport and medicine industries, who implement scanners for quality control, capturing complex geometries and wind tunnel tests. This competition is intended as a gateway project for students looking to get into areas of engineering or R&D, and will award €3,000 to the winner(s) along with the opportunity to present their project at the 13th GOM 3D Metrology Conference in 2017. Some of this year’s speakers included Felix Mönch of Volkswagen AG, and Jeffrey Spaulding from SRAM racing bicycles, both of whom use GOM scanning technology in their product development.

Ideas

Some similar projects we have seen on 3DPI is the optimised use of 3D scanning to create a 3D model of your house. And the extensive preservation of cultural heritage. There could also be some inspiration taken from the influx of 3D printed GoPro modifications, as in this story about a GoPro skateboard mount.

Registration for the competition is open until June 2017. For those interested, you can find out more details here.

Featured image shows scanning a part with ATOS Triple Scan. Screenshot via: GOM on Youtube