Voting shortlists for the 2021 3D Printing Industry Awards are now open. Who do you think should receive top honors this year? Have your say now.

3D design software firm General Lattice has announced plans to expand its operations in the continental United States after raising $1 million via a pre-seed funding round.

Provided by technical services company All Points Logistics’ investment arm AP Ventures, the capital will be used to not only bolster the firm’s lattice-related commercial and Federal R&D initiatives, but build on its client base in the U.S, where it sees its newfound backing as an opportunity to help “facilitate the widespread adoption of AM technology.”

Inside General Lattice’s Studio

Founded in 2018, General Lattice is a software developer that’s known for its CAD integrated GL Studio platform. Built to enable users to design, prototype and manufacture complex 3D printed parts, the program is marketed as the first of its kind to allow for the creation of complex lattice geometries using native B-rep data.

When installed as a plug-in for the Rhino 3D modeling software, the company says that its platform allows adopters to “move beyond traditional design constraints,” and enter “next-gen applications.” For instance, once deployed in commercial, industrial or military settings, the firm’s lattice tools are said to provide users with the chance to improve their part throughput, weight and overall costs.

Alongside its core Studio offering, General Lattice also markets automation tools as well as custom software and material R&D services, in which it pledges to help clients bring their design ideas to life. Given that the firm was founded on the idea of facilitating ‘real-world’ applications, these services are central to its offering, and following its funding round it is potentially one step closer to achieving its goal.

Federal contractor-led funding

According to General Lattice, its newly-raised funding will allow it to meet the “strong demands of a burgeoning additive manufacturing industry.” Specifically, the company now intends to scale its ability to “demonstrate the unique capabilities” of lattice structures to clientele, while ramping up the development of its parametric design tools, which are built to simplify lattice generation processes.

The background of its new investor’s parent company, All Points Logistics, is also significant given its vast experience as a U.S. government contractor. Based in Florida, the firm provides engineering, software R&D and other tech services to Federal clients including NASA and the U.S. Department of Defense, thus General Lattice now has a backer capable of introducing its technology to new users.

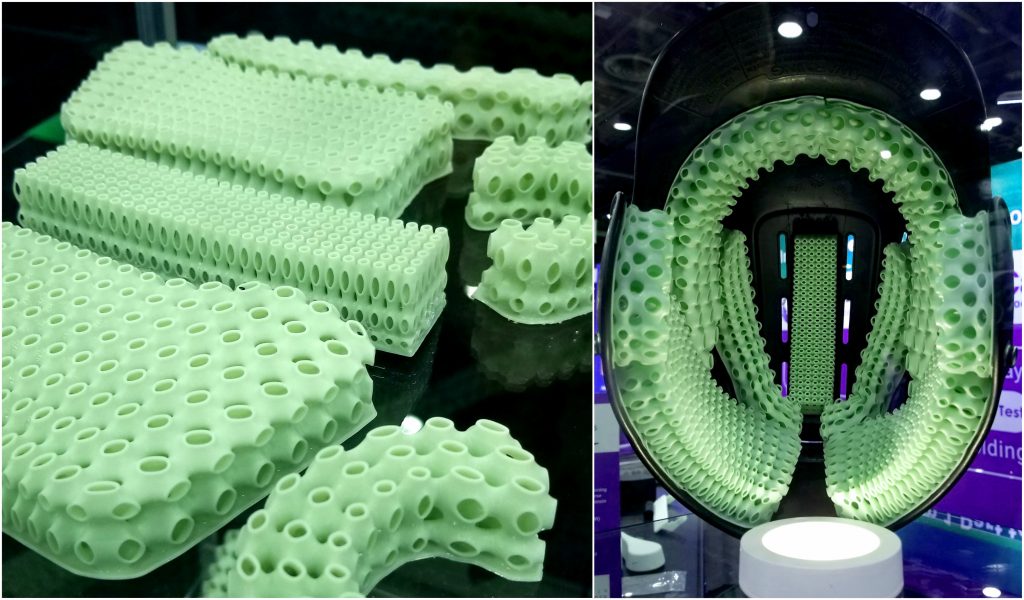

Earlier this month, General Lattice itself was contracted by the U.S Army to improve the shock absorption of DEVCOM Soldier Center helmets using 3D printing and advanced lattice geometries. In practise, the firm aims to achieve this by developing a predictive modeling toolset over the next year, with which it could be able to design superior lattice materials, that have various defense applications.

While General Lattice has said that its fundraising round will enable it to “invest resources” into its DEVCOM R&D program, its CEO Nick Florek has also highlighted the role of its investor as a future ‘partner,’ with extensive contract vehicle expertise.

“We have the support of a partner with proven processes,” explained Florek. “All Points continues to deploy optimized practices based on over twenty years of government contracting, and will allow us to create an environment for passionate innovators in the computational design and digital manufacturing industry.”

Lattice designs in-action

Due to the potential part weight savings, material efficiency gains and impact-resistance qualities it’s possible to achieve using lattice geometries, they’re increasingly finding new 3D printing applications. Earlier this year, service provider Rapid Product Manufacturing (RPM) revealed that it was developing elastic lattice structures, which could be used in both the industrial and consumer goods sectors.

Much like General Lattice, 3D printer manufacturer Carbon has deployed its technologies to create a lattice shockproof design for the world’s first NHL-certified 3D printed hockey helmet liner. Developed for sports goods manufacturer CCM Hockey, the headgear is specifically designed to deliver improved breathability, comfort and protection to its wearers.

On the medical front, chemical firm Linde Group has also partnered with clinical printing specialist 3D Medlab, to develop a means of 3D printing latticed orthopedic products. By identifying a smoother, cleaner method of recycling gases during additive manufacturing, the firms aim to enable the production of titanium medical devices, that are capable of adapting to the movements of the human body.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows All Points Logistics’ Florida headquarters. Photo via All Points Logistics.