Munich-based chemical company Linde Group has partnered with clinical printing specialist 3D Medlab, to research optimizing atmospheric conditions within the 3D printing process.

Gases often play a fundamental role in additive manufacturing, as any impurities that remain in the print chamber, even once purged, can have a detrimental effect on the part being produced. In a newly-announced research project, the companies will conduct a series of atmospheric trials, with the aim of developing a smoother, cleaner method of recycling gases during production. Streamlining manufacturing in this way could enable the creation of complex lattice structures with wide-ranging medical applications.

“We are proud to be collaborating with 3D Medlab on this important and forward-looking project,” said Pierre Forêt, Senior Expert Manufacturing at Linde. “As a customer at the forefront of medical device manufacturing, anything less than optimal product outcomes is critically important to avoid, so it is testament to our gases expertise and know-how that we have been selected to partner in this endeavor.”

The Linde Group in the 3D printing industry

Founded in 1879, and based in Ireland, the Linde Group is one of the world’s largest industrial gas companies, reporting sales last year of $28 billion. The business operates in a variety of markets ranging from automotive and aerospace to food and beverages, but within 3D printing, Linde is known for its ADDvance O2 precision analysis technology.

Launched in 2016, the system enables metal additive manufacturers to analyze and more precisely control the level of oxygen (O2) and humidity within a printer’s chamber. Impurities caused by incomplete purging and small machine leakages can influence the printer’s oxygen level, and the system allowed users to compensate by adjusting the level of argon or nitrogen.

Later, at Formnext 2018, Linde released an updated ADDvance powder cabinet for metal materials which was designed to retain the quality of valuable, sensitive metal powders used during 3D printing. Utilizing its new system, the company agreed to work initially with German 3D printer provider GEFERTEC, and later with 3D Medlab, to investigate gas processing within additive manufacturing.

The benefits of optimized 3D printed parts

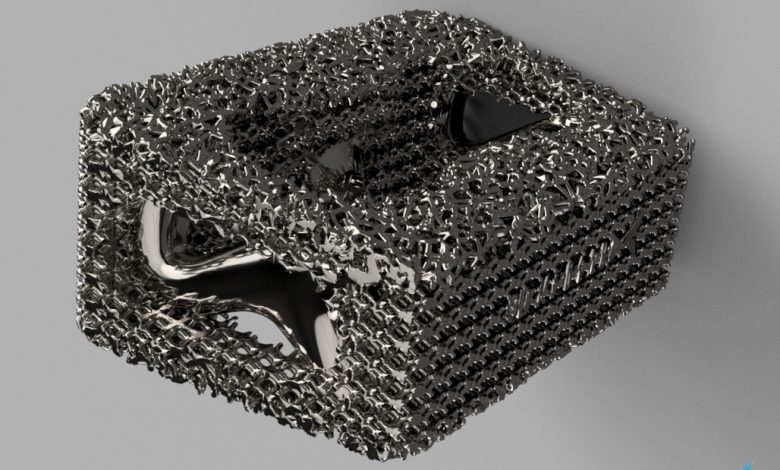

In its latest collaborative project with Medlab, Linde is now seeking to optimize the additive manufacturing process in order to create enhanced products for the medical sector. 3D printed clinical parts present a number of advantageous features compared to their conventionally produced counterparts. Multifaceted, latticed orthopedic products are more able to accurately mimic the movements of the human body, and this allows components to better assimilate into the patient’s own bone and tissue structure.

Additive manufacturing could also accelerate the production of such components, by ensuring that the process is repeatable, and yields the maximum possible part finish. Nonetheless, in order to achieve a high-quality reproducible 3D printing method, the atmosphere in the print chamber needs to be optimal. If fumes created during production remain on the part, for instance, the component will require post-production cleaning, which acts to lengthen the overall manufacturing time.

Additionally, even extremely small variations in oxygen content can impair the mechanical or chemical properties of metals that are sensitive to atmospheric imbalance. In materials such as titanium and aluminum alloys, for instance, this can affect the composition of the end product. As a result, Linde and 3D Medlab have agreed to conduct a number of research trials, with a particular focus on the Ti-6AI-4V titanium alloy.

Linde and Medlab’s collaborative project

As part of their collaborative effort, the partners will conduct a series of atmospheric tests on a new helium/argon gas mixture that Linde has developed especially for the project. Linde will also provide Medlab with its patented ADDvance O2 precision measuring and analysis technology, as the companies seek to ensure the optimal mix of gases within the print chamber. The machine enables the precise, granular control over the oxygen concentration and humidity levels required to optimize conditions in their experiments.

While the current partnership between Linde and 3D Medlab is focused on Ti-6AI-4V lattice structures, the companies are planning to continue working together in the future. Nickel titanium materials are of particular interest to the firms due to their shape memory and elasticity qualities, which make them an ideal candidate for surgical products such as next-generation stents. As a result, further 3D printed medical products could be the target of further research for the duo’s collaboration.

“Our experience with Linde shows that they are as committed to the same high standards of precision and excellence in additive manufacturing that we are,” concluded Gaël Volpi, CEO of 3D Medlab. “Full regulatory compliance is a fundamental cornerstone in our engineering and design process, and our customers trust us to ensure all proper measures and controls are in place.”

You can now nominate for the 2020 3D Printing Industry Awards. Cast your vote to help decide this year’s winners.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a metal 3D printed product manufactured using Linde’s 3D printing technology. Photo via the Linde Group.