GEFERTEC, the German developer and provider of 3DMP metal 3D printers and technology, is opening a manufacturing facility in Danville, Virginia.

The facility will be the company’s first in the U.S., and will lead to the establishment of eight new jobs. Initially, the new manufacturing space will launch at the Institute for Advanced Learning and Research (IALR) in Danville, remaining there for two years until relocating to a permanent location in Danville/Pittsylvania County.

The GEFERTEC U.S. facility will be aided by $1.9 million of capital investment. This includes a $45,000 grant from the Tobacco Region Revitalization Commission as part of its Tobacco Region Opportunity Fund (TROF) program. The cost for temporary space at the IALR will be covered by the Danville Pittsylvania Regional Industrial Facility Authority (RIFA).

As told to ABC 13 News, Andrea Clark, President of GEFERTEC, states

“GEFERTEC is excited to announce the opening of our Danville – Pittsylvania County location as our first U.S. location for our 3DMP additive manufacturing business.”

Bringing 3DMP to the U.S.

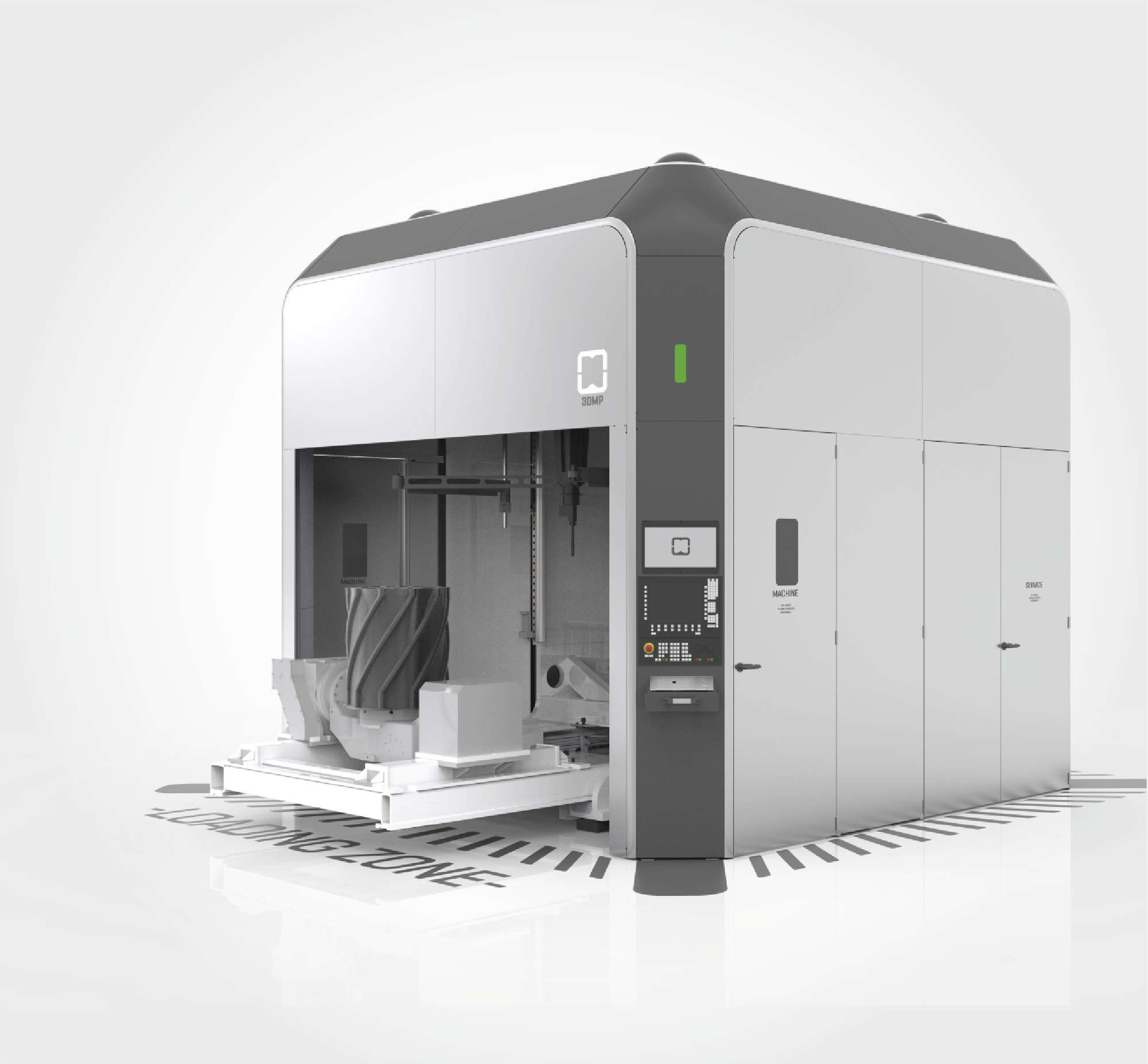

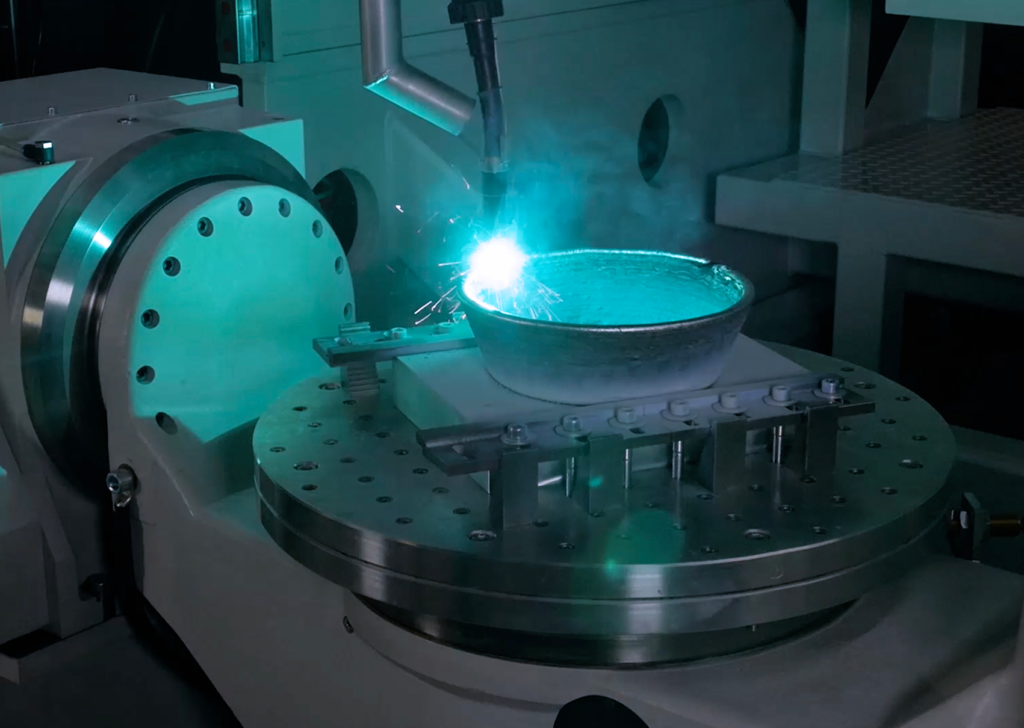

GEFERTEC 3DMP technology uses wire-arc welding based metal additive manufacturing to create near-net-shape components. According to GEFERTEC, 3DMP technology promises to eradicate waste with “nearly 100% material utilization,” and cost savings of “up to 60% versus conventional manufacturing.” The company also claims that the technology can simplify the process of conventional manufacturing to three steps: warehousing, manufacturing and then finishing with the integration of an optional milling system.

Currently GEFERTEC has developed four 3DMP machines in its portfolio. This includes the arc603, a 3-axis machine capable of creating components up to 3 m³, with a maximum mass of 3000kg and the arc605, a 5-axis machine with a maximum capacity of up to 0.8 m³ and 500 kg mass.

GEFERTEC has also developed the arc405, a 5-axis machine with 0.06 m³ capabilities and a maximum mass of 200 kg, and the arc403, the 3-axis machine selected by Airbus for use in the aerospace industry.

The systems are suited as a manufacturing solution for metalworking companies in a variety of industries, as well as for research and development institutions. Tobias Roehrich, CEO of GEFERTEC, adds that “[The U.S. facility] is in alignment with our longterm commitment to Danville and the Institute for Advanced Learning and Research and we are excited to expand our business to the U.S.. Danville has been chosen for its excellent business and community support and its involvement in the advanced manufacturing sector.”

Helping manufacturers produce metal parts

Various companies are using 3DMP machines to improve their manufacturing capabilities. For example, Aircraft Philipp Group is another aerospace company utilizing GEFERTEC’s 3DMP technology. A German supplier of aeronautic metals, the company is using the arc605 to produce components of up to two tons in mass, thereby responding to user demands for larger parts.

Over in the railway industry, Deutsche Bahn has also employed 3DMP additive manufacturing in its production processes. The company implemented 3DMP to improve the availability of hard-to-procure spare parts.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows GEFERTEC application center. Photo via GEFERTEC.