FELIXprinters, a Netherlands-based desktop 3D printer manufacturer, has announced the commercial availability of its BIOprinter, marking the company’s move into the bioprinting market.

First introduced by FELIXprinters at 2019’s Formnext exhibition, the BIOprinter has been developed with key features that are specifically designed for medical, scientific, and research applications. These features include syringe cooling, print bed cooling and heating, a dual head system, easy syringe positioning for ergonomic access, and automatic bed levelling. Development of the FELIX BIOprinter was carried out in partnership with Training4CRM and the Technical University of Denmark (DTU), with funding from the European Union Horizon 2020 Programme.

“The BIOprinter has been designed to be the ultimate bio research instrument in a cost-effective package. It has been developed alongside the brightest minds in the bioprinting sector,” explains Wilgo Feliksdal, Co-Founder of FELIXprinters.

“The BIOprinter consists of an adaptable and flexible ecosystem to ensure that it can meet a wide range of researchers’ needs without generating unnecessary costs.”

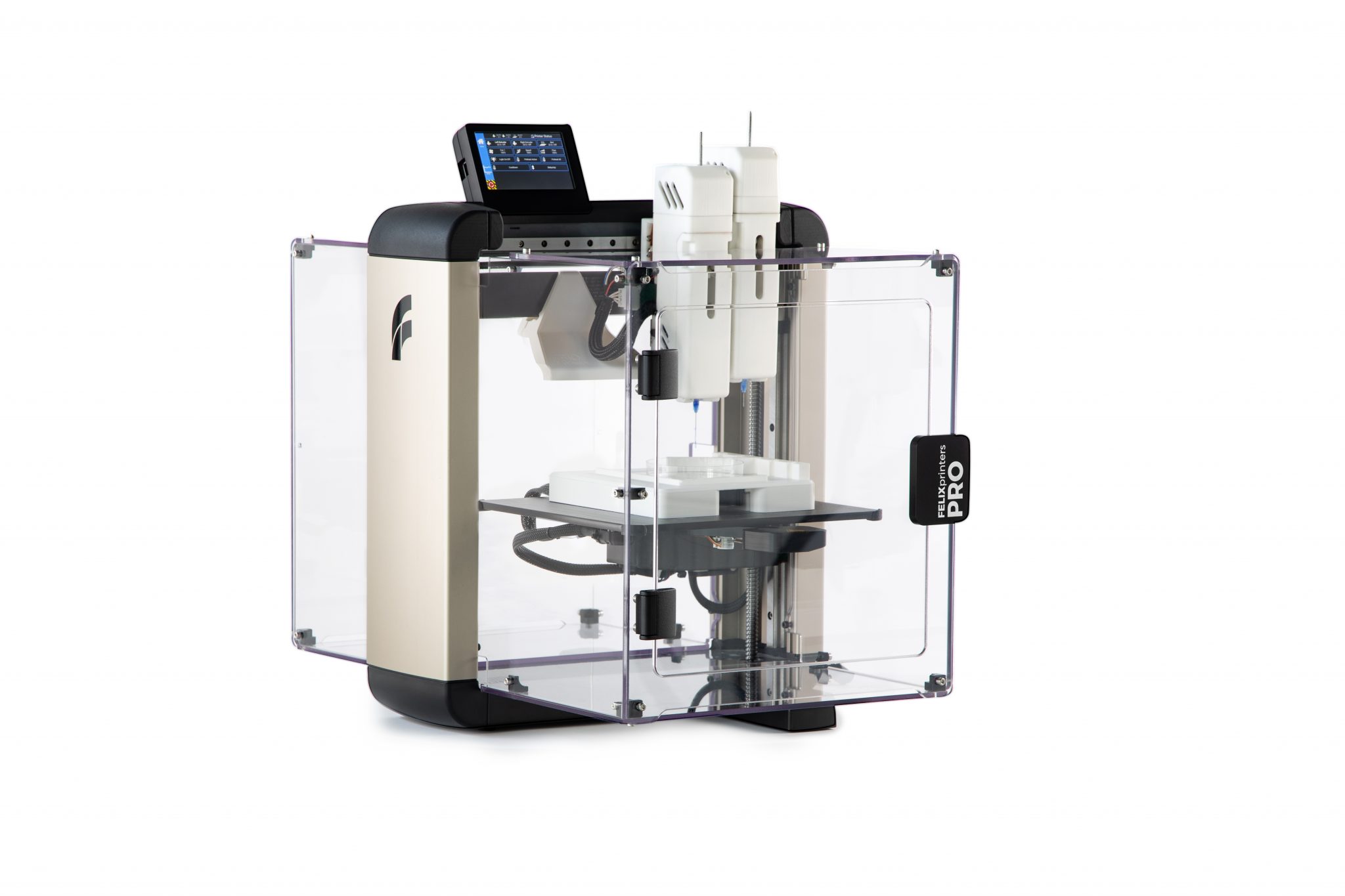

FELIXprinters Pro series

Founded in 2011, FELIXprinters was established by Guillaume Feliksdal and his father Wilgo Feliksdal, a mechanical engineer. The company initially operated out of two rooms when it began taking orders for its first 3D printer, the Felix 1.0. To fulfil these requests, Guillaume and his father had seven Felix 1.0 printers replicating themselves in the two rooms. As the firm grew, the duo outsourced the production of the parts. Key to the design of FELIX 3D printers is a minimalist and upgradeable setup, ensuring fast assembly, upgradeability, and functionality for improved ease of use.

Since then, the company has perhaps become best known for its Pro series of desktop 3D printers. In 2015, FELIXprinters released the FELIX Pro 1, which was then followed by the FELIX Pro 2. The latter was designed with an emphasis on ease-of-use, and is a previous winner at the 3D Printing Industry Awards, having received the most votes from readers in the category “Personal 3D Printer of the Year (FFF/FDM)” in 2017. In early 2019, FELIXPrinters then released the FELIX Pro 3 3D printer, designed to maximize productivity and efficiency. In that same year, the company also launched two additional large-format FDM printers in the series, the Pro L and XL.

The BIOprinter

FELIXprinters explains that its entry into bioprinting comes at a time where the market is expected to grow at a compound annual growth rate of nearly 20 percent up to the mid 2020s. Such growth, the company claims, is driven by increased healthcare demands, as well as the search for an alternative to organ donation and tissue repair. Additionally, bioprinting meets the increasing demand for personalized patient-specific healthcare solutions.

FELIXprinters built its BIOprinter using the same chassis it used to construct its previous FDM 3D printers, in order to rely on “tried and tested technology.” Thus, in accordance with the older systems, the BIOprinter has been designed to be easily upgradeable. Development of the system was carried out alongside Training4CRM, a consortium established to address gaps in Cell-based Regenerative Medicine (CRM). Training4CRM is funded by the European Union Horizon 2020 Programme.

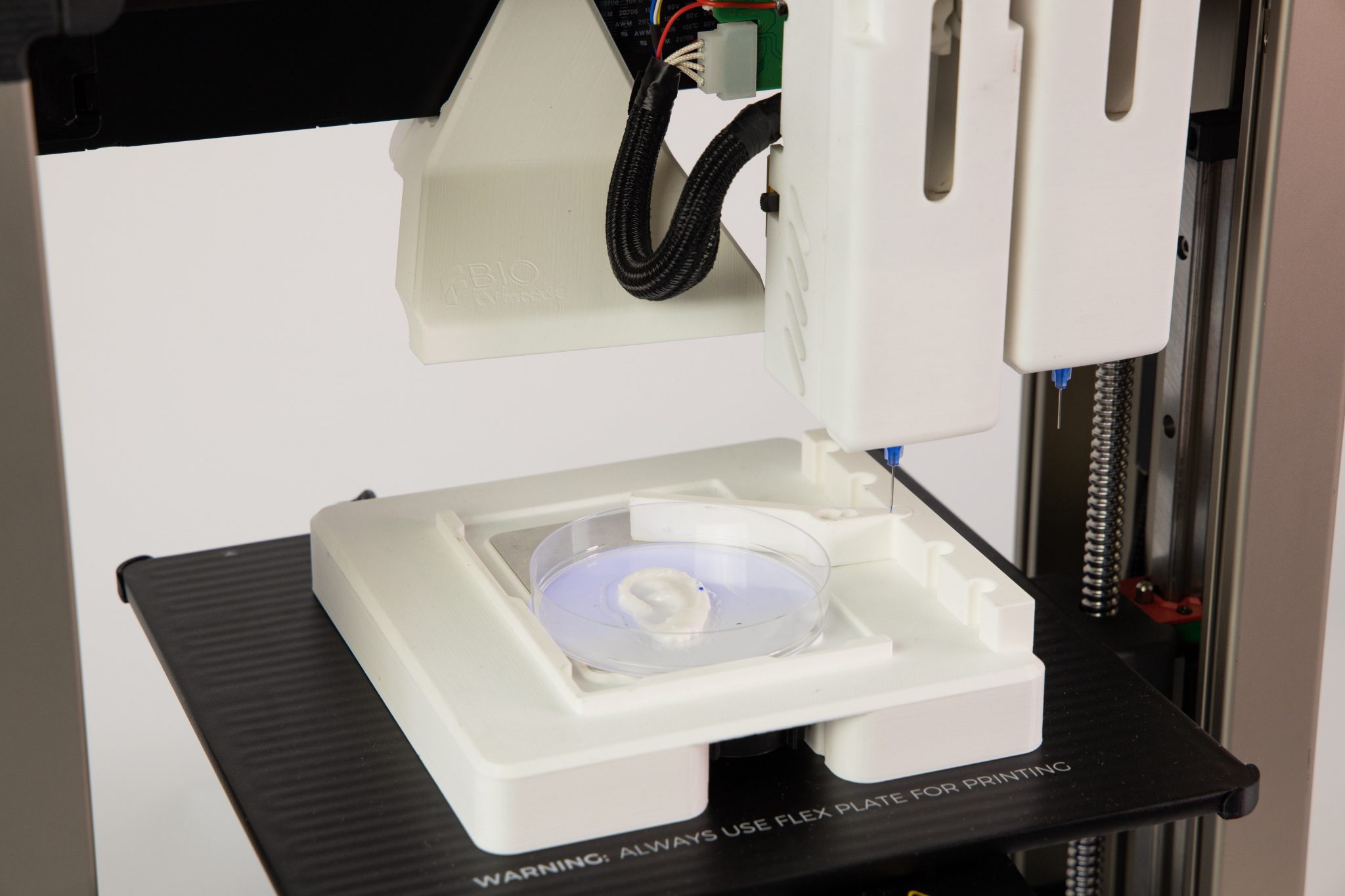

The BIOprinter includes dual sterilizable printheads which have a modular design to support changeovers. Separate heads are available for printing in different bio-inks at the same time. This allows users to integrate different material properties into a single scaffold structure. Additionally, the BIOprinter leverages motors that can extrude a range of different viscosity of materials.

The system also has an automatic bed levelling system in order to improve the quality of the final print, alongside a precise motor for accurate material flow versus alternative air pressure systems. FELIXprinters explains that users of the BIOprinter will benefit from print heads that are easy to sterilize, alongside compatibility with standard slicing software: “One major advantage is the source control system which enables the user to use standard slicing software and make changes themselves if needed. Also, syringes are not restricted to expensive brand-specific or in-house produced products that essentially drive up operating costs. The machine instead has been designed to use a standard 5ml syringe, and standardized petri dishes and culture plates, so there are no limitations on auxiliary parts and materials,” adds Feliksdal.

Technical specifications and pricing

Below you will find the technical specifications for the FELIX BIOprinter. The system is priced around €9,650.00. Visit FELIXprinters’ website to receive a quote.

| BIOprinter specifications | |

| Layer Resolution | to 50 microns |

| Build Plate | Aluminium sandwich plate with steel flexplate |

| Print head | Dual syringe operation |

| Syringe Specs | 5 ml syringe(s) |

| Build Speed/s | Recommended build speed is 20 mm/s. Speed depends on material viscosity |

| Typical print accuracy | ± 0.05 mm for sizes below 20 mm |

| Syringe Min/Max print temperatures | 0-50 ˚C |

| Syringe heat up time / cooling times | 10 seconds |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s event? Have your say now.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows print heads on the FELIX BIOprinter. Photo via FELIXprinters.