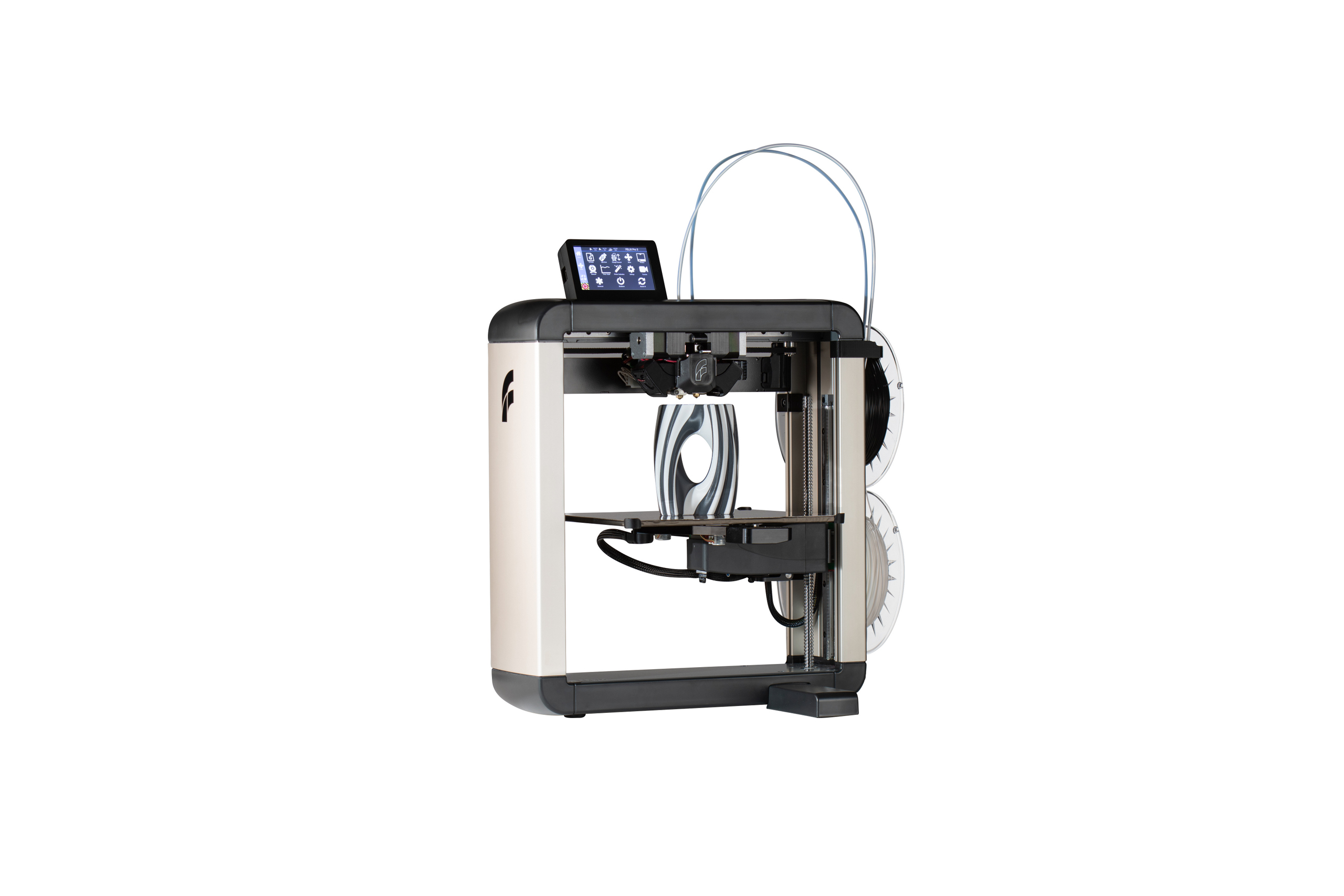

FELIXprinters, a Netherlands-based desktop 3D printer manufacturer, has released its latest additive manufacturing system, the Pro 3, designed to maximize productivity and efficiency.

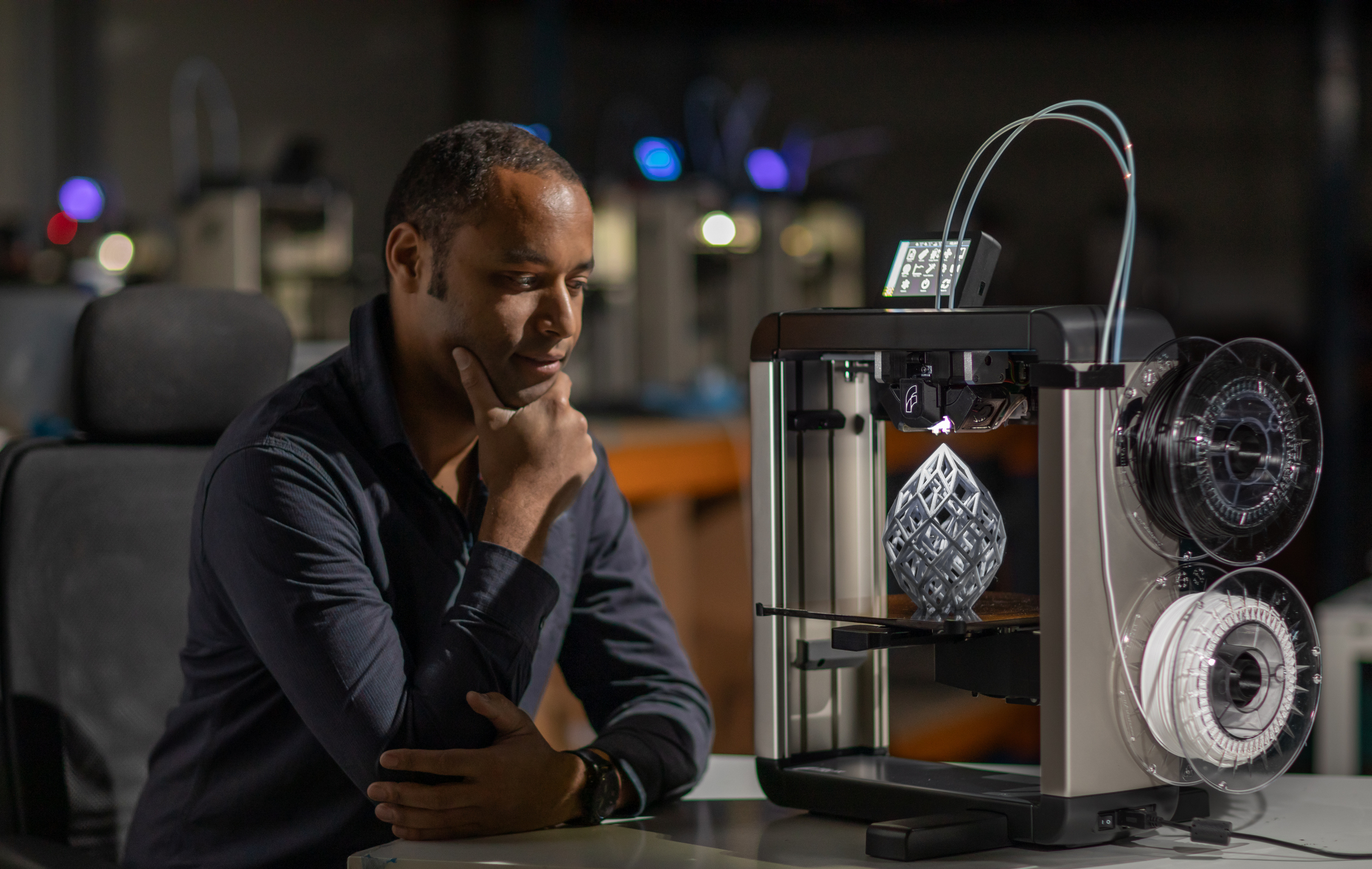

“The Pro 3 has been developed to integrate seamlessly into industrial workflows, whether that is in an office, a workshop, lab or factory environment,” said Guillaume Feliksdal, Founder and Director of FELIXprinters.

“The priority was to deliver a 3D printer that produces optimized print results — every time! This is what customers tell us is most frustrating for them in their day-to-day operations with 3D printing, and these are the issues we set out to address with the Pro 3.”

Redesigning desktop 3D printers

In 2015, FELIXprinters released its range of professional desktop 3D printers with the FELIX Pro 1. It’s successor, the FELIX Pro 2, designed with an emphasis on ease-of-use, was previously recognized by the 3D Printing Industry Awards receiving votes from readers in the category “Personal 3D Printer of the Year (FFF/FDM).”

Last year, FELIXprinters announced a repositioning of its portfolio of products and services to meet the changing demands of the 3D printing industry. In particular, the company recognized the demand from industrial customers to automate and optimize production.

Feliksdal added, “Our team at FELIXprinters all have technical engineering backgrounds, so we know that “quality in” equals “quality out”! We have sourced extremely high-quality components to ensure that the Pro series of printers are both robust and reliable – and these are the cornerstone of the new FELIX Pro 3.”

The FELIX Pro 3

Thus, the FELIX Pro 3 is built to “offer the highest possible price/performance ratio in its class with dedicated features that ensure minimal downtime and optimal performance as well as high-quality parts.”

With a build Volume of 237 x 244 x 235mm, the FELIX Pro 3 is built from custom designed anodized aluminum, which according to FELIXprinters, is the same aluminum used in aerospace and military designs. In addition, its frame is made from powder-coated steel parts for maximum rigidity.

Furthermore, the printer features a dual head printing system within its open system which enables more design freedom. The system also claims to be “one of most silent printers available” emitting 32 decibels of noise.

Technical specifications and pricing

| Build Volume | 235 x 244 x 235mm |

| Weight | 11.5kg |

| Print Technology | FFF |

| Layer Resolution | Low: 250 microns Normal: 200 microns High: 100 microns Extreme: 50 microns |

| Material Compatibility | Recommended: PLA, PETG, ABS-X,PVA

Specials: Any filament which melts under 275 °C |

| Nozzle Diameter | 0.35 standard. Optional 0.5 and 0.7mm

|

| Nozzle Temperature | Up to 275 °C |

| Filament Diameter | 1.75mm |

| Build Plate | Quick swap, magnetic flexplate. Up to 105 °C |

| Build plate leveling | Fully automatic motorized |

| Build speed | 0.35mm nozzle up to 18 mm3/s (ABS @ 250°C) |

| Printer Communication | Standard: USB serial, Standalone via micro SD card (included) Touchscreen: USB stick, WIFI, Wired Ethernet |

The FELIX Pro 3 3D printer is now available from €2,599.00.

Nominate for the upcoming 3D Printing Industry Awards 2019.

For the latest 3D printing news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Seeking a fresh start in the new year? Visit 3D Printing Jobs to commence your career in additive manufacturing.

Featured image shows the FELIX Pro 3 3D printer. Photo via FELIXprinters.