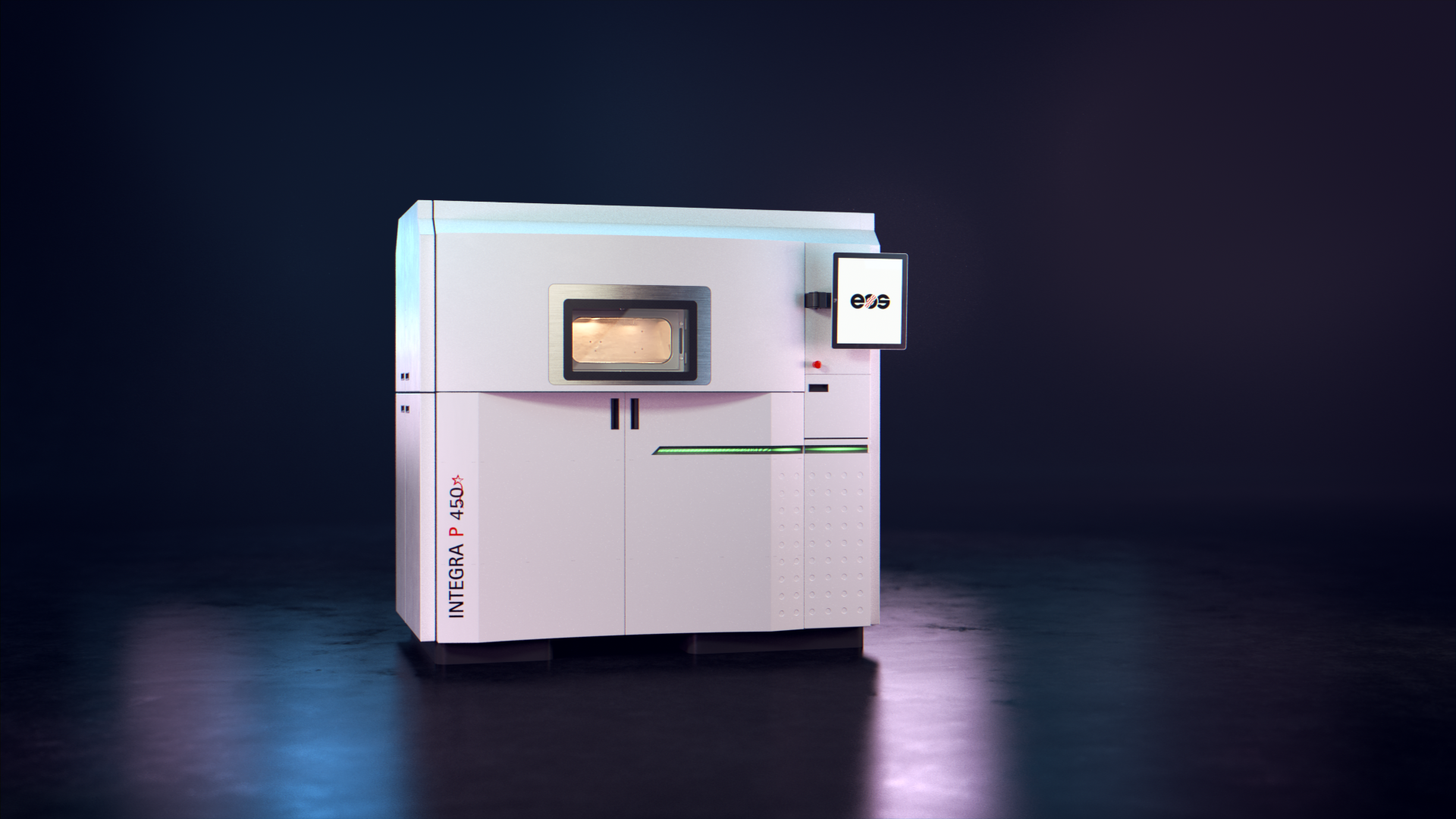

EOS North America has launched its new INTEGRA P 450 3D printer.

The mid-range temperature, polymer SLS system aims to bridge the gap between prototyping and serial production with a scalable, modular design. With a maximum temperature of 300°C, the INTEGRA P 450 caters to a wide range of SLS-suitable polymers for industrial applications.

David Leigh, COO of EOS North America, stated: “Our customers spoke, and we listened. Every aspect of the INTEGRA P 450’s design – from its serviceability and material flexibility to the thermal imaging camera and workflow-based approach – was thoughtfully measured against customer feedback to create a machine that can easily scale and bridge the gap, from R&D and prototyping, to serial production.”

Powder bed fusion technology

Founded in 1989, EOS made its 3D printing debut with the STEREOS 400 system, one of the first business-ready SLA machines to be developed. Since then, the company has moved into powder bed fusion systems with a focus on polymer sintering in the last decade.

EOS’ portfolio of SLS systems includes but is not limited to the FORMIGA P 110 Velocis, a compact cost-efficient system suitable for users just entering the production-grade AM market. The EOS P 396, optimized for serial parts, provides a higher rate of output with repeatable tight tolerances. The EOS P 770, housing two lasers, is suitable for large part production and high-throughput industrial manufacturing.

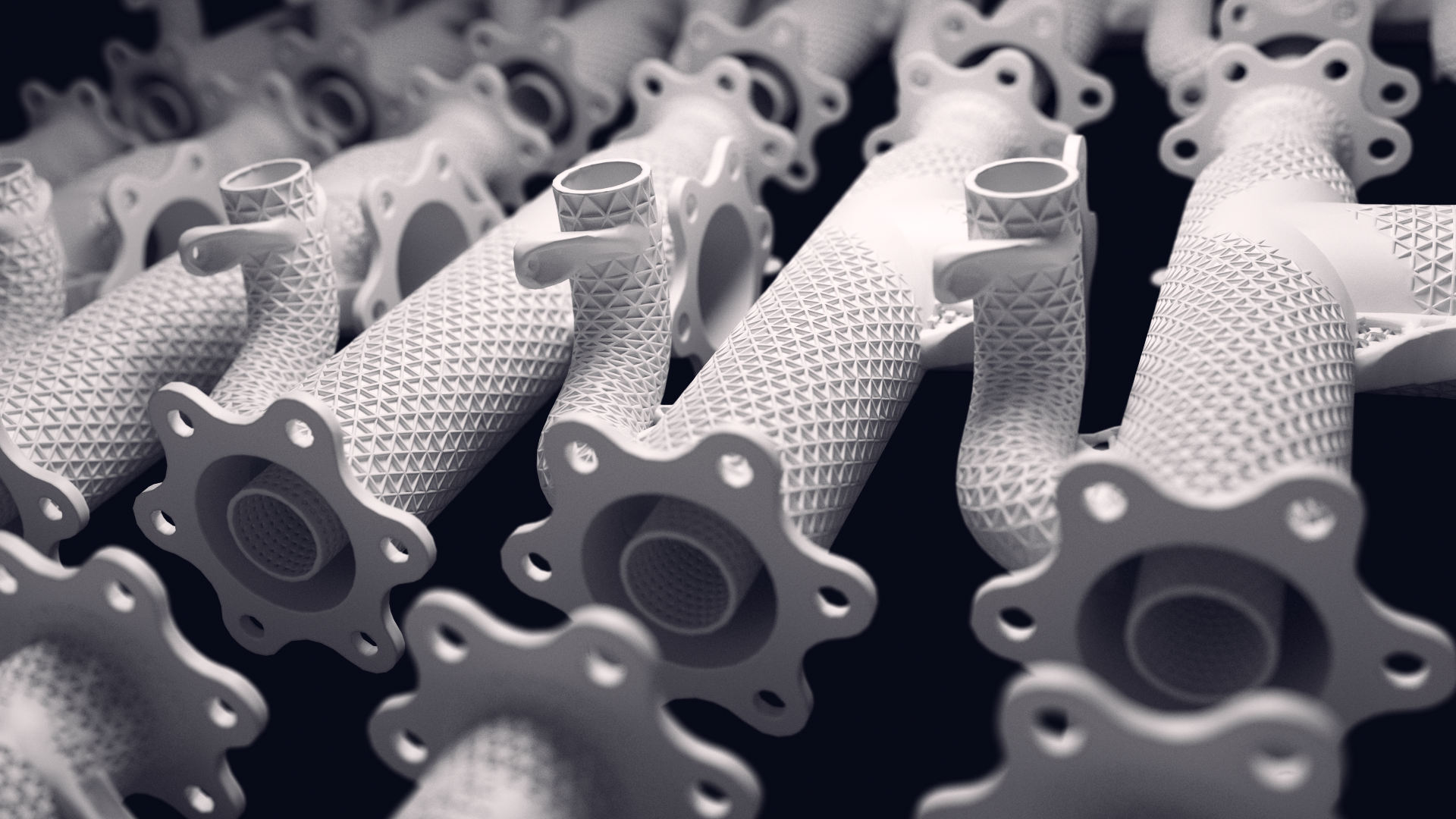

With the release of the INTEGRA P 450, EOS intends to provide its customers with an adaptable system. Scalability and versatility are at the heart of this 3D printer, allowing INTEGRA P 450 users to manufacture components for a wide range of applications.

The INTEGRA P 450

The P 450 is capable of temperatures of up to 300°C, allowing for the 3D printing of a broad range of polymers. Its 8 independently controlled quartz heating zones result in more consistent part production as well as an efficient use of the 420x420x500mm build volume. The printer’s improved process chamber enhances thermal uniformity to ensure production-grade mechanical properties. A thermal imaging camera integrated into the system provides real-time thermal analysis of part beds for superior in-situ quality control.

An exchangeable optics tray and upgradable build volume were developed with significant input from service professionals, making the system all the more serviceable to reduce downtime. Optional accessories include additional exchange frames, changeable laser window units, additional multibox feed system units, and a reduced build volume adaptor that is currently in development.

A CO2 120W laser provides a scanning speed of 12.7m/s. A dual-roller recoating system reapplies powders at speeds of up to 0.4m/s, resulting in a typical build rate of 25mm/hour. New plane segmentation capabilities allow for different layer thicknesses within the same part, ranging from 0.10mm to 0.18mm. EOS’ proprietary EOSPRINT 2 software enables simple progression from CAD model to 3D printed part.

Technical specifications and pricing

Below are the technical specifications for the INTEGRA P 450. The system is priced at around $499,000. Orders are already being accepted, although availability is currently limited to North America. Visit the INTEGRA P 450 website for more information.

| Build volume | 420 x 420 x 500 mm |

| Laser type | CO2 120 W (70 W available on request) |

| Building rate | 25 mm/hour |

| Layer thickness | 0.10 mm to 0.18 mm (depending on material) |

| Scan speed during build process | Up to 12.7 m/s sky-writing |

| Power supply | 240 VAC, 3 Phase / 40 A – peak operating current 30 A |

| Dimensions | 2.08 x 1.32 x 2.46 m |

| Recommended installation space | Min. 4.6 x 4.1 x 3.3 m |

| Software | EOSPRINT 2 |

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows INTEGRA P 450. Photo via EOS North America.