Metal additive manufacturing has hit on a clear niche within the healthcare industry for producing small and complex medical grade implants at scale. Many 3D printing companies working within medicine have a portfolio of devices for the purpose, typically including a sample of 3D printed cages used to support the spine.

However, in what is tipped to be a first in the U.S., the Food and Drug Administration (FDA) has cleared a 3D printed cervical device that can be used in a number of injuries/defects from the middle to the top of the spine.

Made by Cellular Titanium technology

The multilevel cervical cage was made by Emerging Implant Technologies GmbH (EIT) using its trademark Cellular Titanium® technology.

Cellular Titanium devices are 3D printed in a process of selective laser melting (SLM). By precisely programming the laser’s movements, EIT is able to make implants with a core that mimics the cancellous (“spongy”) and cortical (hard) structure of bone.

When implanted in the body, biomimetic lattice-like structure ecourages tissues to grow through the center and graft broken pieces of bone back together.

7 levels of treatment

The remarkable quality of EIT’s cervial implant is that it is a 3D printed device that can be applied across 7 levels of damage to the spine.

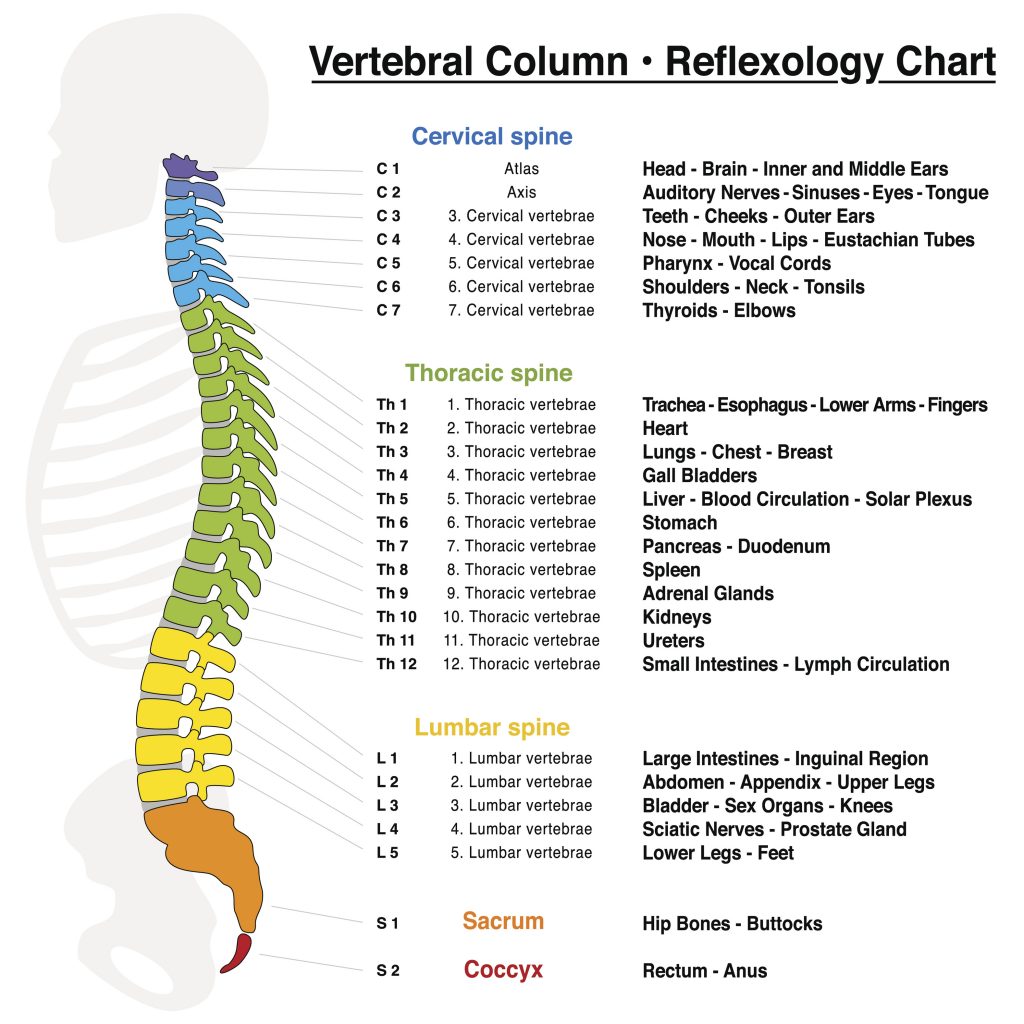

In reference to the international chart for spinal cord injuries, EIT’s cervical implant can be applied to levels C2 to T/Th1 relating to the mid and upper segments of the spine. At the upper level (C2) the implant can be used to treat injuries to the auditory nerves, sinuses, eyes and tongue. The lower levels encompass the shoulders, neck, elbows, arms and fingers.

Guntmar Eisen, Founder and CEO of EIT, comments, “This is another important regulatory milestone for EIT,”

“Only very few cervical cages are approved for multilevel use and we are poised to quickly enter the US market with the most advanced technology and state of the art FDA labeling and compliance.”

More from EIT

The FDA clearance of EIT’s multilevel cervical cage is an extension of the company’s existing Cellular Titanium® label first approved summer 2017.

More recently, EIT also signed a contract with the Hospital Corporation of America (HCA), the largest group purchasing organization (GPO) in the United States covering almost 400 hospitals and surgery centers across the nation.

Stay up to date with the latest FDA advances by subscribing to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook here.

Nominate the best in medicine in the 2018 3D Printing Industry Awards here.

Featured image shows surface structure of an FDA approved 3D printed cellular titanium implant. Image via EIT