Chinese 3D printer manufacturer Farsoon Technologies has unveiled expansion plans after achieving its highest ever monthly turnover during November 2021.

Across its material, service and application offering, Farsoon managed to generate $15 million over the course of the month, including the sale of over forty machines. Following its recent rise in demand, the firm now intends to grow its capacity via a new polymer powder production facility, designed to enable it to better meet the needs of its client base.

“Despite the challenging pandemic situation, Farsoon has been able to deliver strong performance, supporting recovering global industrial demand,” said Don Xu, Director of Farsoon’s Global Business Group. “With continuous technology innovation and increasing market share, Farsoon has proved itself a strong and stable additive manufacturing partner that customers can trust.”

Farsoon’s market expansion

Since being founded by ex-DTM Corporation (now 3D Systems) technical director Dr. Xu Xiaoshu in 2009, Farsoon has gone on to establish itself as one of China’s leading powder bed fusion (PBF) 3D printer manufacturers, and it continues to grow its metal and polymer portfolio along with its global addressable markets.

After expanding into the U.S by setting up Farsoon Technologies-Americas in Austin, Texas during 2017, the firm launched its first Continuous Additive Manufacturing Solution (CAMS) system, the HT1001P. This was followed by the establishment of Farsoon Europe GmbH in Stuttgart, Germany a year later, and the roll-out of the company’s next-gen ‘flight’ polymer 3D printing technology a year after that.

Since then, Farsoon has continued to add larger and more powerful machines to its metal 3D printing offering, including its cost-efficient FS273M and heavy-duty FS721M systems, which pack up to two and eight lasers respectively, enabling them to open a wider variety of automotive, tooling and industrial applications to users.

The success of these technologies has been borne out in periodical sales updates, with the company announcing its largest ever polymer printer order in September 2020. Late last year, it was also revealed that Farsoon doubled its revenue between Q1 and Q3 2020, and more recently, the firm announced that it had reached a landmark, having installed 500 3D printers worldwide.

Metal 3D printing leads the way

Due to the fact that Farsoon isn’t publicly-traded, we only tend to get an insight into its finances when it reaches significant sales milestones. As a result, it can be difficult to contextualize the firm’s revenue figures, but given that its latest numbers represent its highest of any month to date, it’s safe to say that Farsoon is enjoying something of a mid-pandemic sales boom.

According to the company, it achieved “increased growth across its whole product portfolio” during November 2021, thanks largely to its metal-related offering which drove more than 60% of this demand, with its machines being bought to power “several major projects” in the aerospace, transportation, medical, molds and tooling and service bureau sectors.

In particular, Xu has hailed the growth of Farsoon’s metal printing base in Europe and North America as an important step, and said that due to its strong machine order backlog, he’s “confident of its positive outlook for 2022.” To support its ongoing expansion, the firm has also ramped up its R&D spending, grown its dedicated team from 300 to 450 staff and unveiled plans to build on its material capacity.

“In the year of 2021, Farsoon has been rapidly growing our team,” added Hope Hou, General Manager of Farsoon. “We are also glad to share that we are well on the way to completing our new manufacturing facility expansion with a new dedicated site for increased polymer powder material production; in order to offer high quality machine and material solutions to our global customers.”

How do Farsoon’s figures compare?

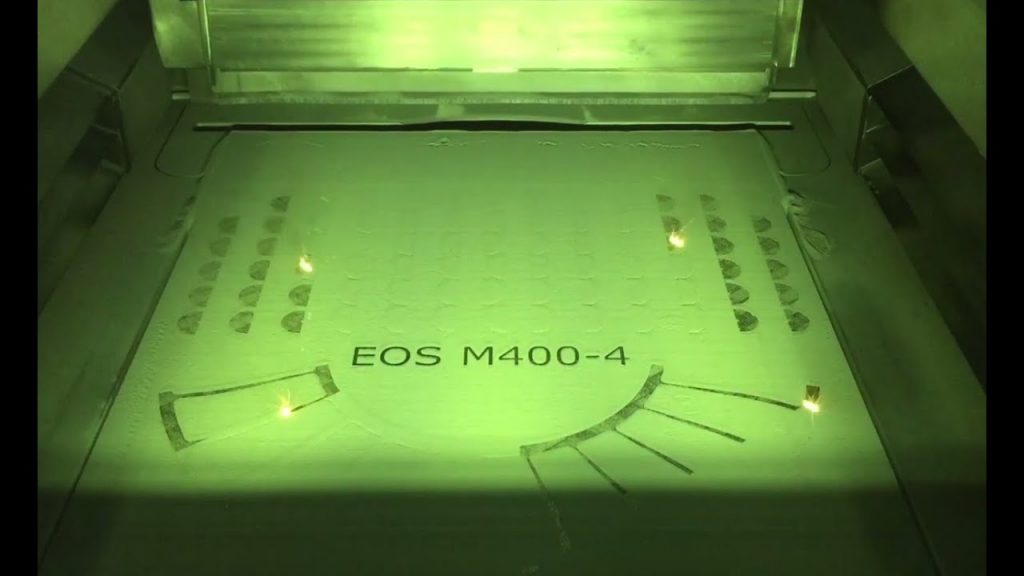

Given that fellow market leader EOS is also traded privately, it’s somewhat difficult to assess how Farsoon’s figures stack up against those of its competitors, but there is some evidence to suggest that PBF manufacturers are seeing rising demand.

Metal 3D printer manufacturer TRUMPF, for instance, announced in July that it expects to have generated €3.3 billion in product orders, of which additive systems are a part of, for the 2020/21 financial year. Although the firm is also traded privately, thus it doesn’t publish its full results, it does provide occasional insights into its business, with its latest revealing a growing demand from Chinese clientele, particularly those in automotive.

Elsewhere in Germany, publicly-traded PBF system manufacturer SLM Solutions, published flat revenue figures for the first half of 2021 earlier this year. However, at the time, the company’s CEO Sam O’Leary maintained that he expects “business to continue to pick up” during H2 2021, due in part to the firm’s significant €30.2 million order backlog.

In the UK, meanwhile, Renishaw reported a pre-tax profit of £120 million within its FY 2021 financial results. Despite posting very healthy figures, including a total revenue of £566 million, the company’s 3D printing sales actually fell during the period, after the division underwent a ‘Fit for the Future’ resizing which saw it refocus on productivity, reduce its cost base and prioritize ‘significant design projects.’

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured shows Farsoon’s FS421M metal 3D printers installed at Falcontech Super AM Factory. Image via Falcontech.